Tips on improving the design of Sheet Metal Prototyping | 2020

2020-06-09How to improve the Sheet Metal Prototyping Design?

Sheet Metal prototyping has become an imperative part of the modern industry. If we say that both fabrication and sheet-metal prototyping is the back of the industry, we would not be wrong. This prototyping holds great importance in the aerospace, automotive, and several other industries.

Produsente wêreldwyd gebruik plaatmetaal vir die vervaardiging van onderdele, panele, omhulsels, hakies, toestelle en panele. Om die kwaliteit van die produk te verseker, is dit belangrik om 'n sterk prototipe van hoogwaardige plaatmetaal te hê.

Die kwaliteit van hierdie onderdele sal 'n groot verskil maak. Boonop is dit belangrik om die regte en foutlose plaatmetaalontwerp te hê. Die regte ontwerp sou immers die robuustheid van die prototipe verhoog.

Hierdie blogpost fokus op 'n paar belangrike wenke om die ontwerp van u plaatmetaalprototipe te verbeter.

Wenke om die ontwerp van prototipes van plaatmetale te verbeter

There are several factors that need consideration. These factors play an important role when it comes to defining the quality of the prototype. For starters, it is important that you partner with a professional and experienced prototyping manufacturer such as the Essaii.

A reasonable and accurate design holds great importance as well. If the design meets the required expectation, only then will it serve its purpose to perfection. The design lacking its ability to meet the requirement, you eventually cause the downfall of its respective product.

According to researches, manufacturers spend about 30% of their time fixing the problems that were in the design. The reworking of the parts leads to heavy, but thanks to modern prototyping, this all can be resolved at a minimal cost and within budget.

There is no denying the importance of correct design, achieving it is a different story. Here are some effective designs tips that would improve the overall quality of your prototyping.

Clear Design Purpose

It is crucial for engineers and designers to have a clear purpose for their design. In addition, they need to have a proper plan in place to make sure that the sheet metal design is easy for the manufacturer as well as cost-effective.

Several factors need consideration during the designing phase including the thickness, mechanical properties, function, tooling methods, features, and tolerance. All these factors need to be in accord with the actual application.

Focus on Sheet Metal Prototyping Hole Designs

Manufacturers mostly use sheet metal to make a metal prototype. They understand that the sheet metal would need slots for screw, holes, interlocking sections, bolts, among others. These things would be part of the design.

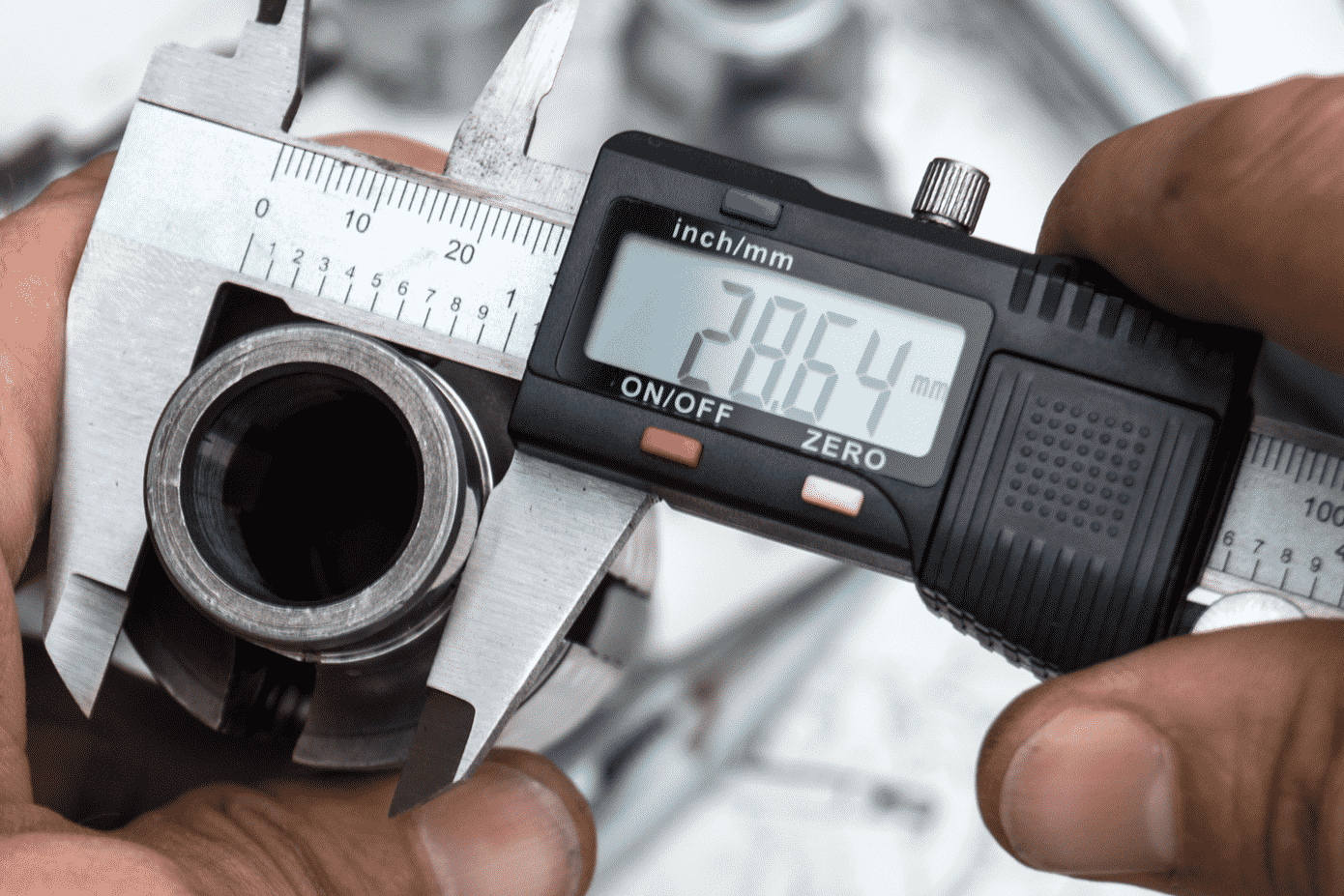

The engineers would specify the size, alignment, positions of the holes during the design phase. All these things are extremely important. Below, are some rules that you should follow:

Sheet Thickness

It is important that the thickness of the sheet is less in comparison to the hole’s diameter. A thicker sheet would lead to higher punch loading, something you would want to avoid. In addition, it would require excessive burr and a longer time to burnish. Also, a thick sheet would lead to slug-pulling. Thus, having an adverse impact on the metal sheet’s punch and lifespan.

Hole Spacing

Nog 'n belangrike reël wat u moet volg, is om die regte spasie tussen gate te hê. 'N Goeie vuistreël is om ruimte te hê wat gelyk is aan twee keer die dikte van die vel tussen elke gat. Die regte spasie tussen gate verseker immers die robuustheid van die metaalplaat en voorkom dat dit vervorm word. Dit verhoed ook die buigproses.

Gate on the Edge

As u gate aan die rande van die laken opneem, moet u seker maak dat die regte afstand is. Vir hierdie gate moet die spasie tussen elke gat ten minste gelyk wees aan die dikte van die vel.

Die regte vennoot

As u met die regte vervaardiger van prototipes saamwerk, is u minder geneig om foute te maak in die ontwerpfase. Immers, hulle ervare en kundige personeel sou daar wees om 'n foutbestande ontwerp van prototipering van staalmetaal te verseker.

Bestuur verdraagsaamheid

For a metal sheet, tolerance is important. Therefore, as an engineer, you need to pay close attention to this aspect of prototyping. When we talk about managing tolerance, you need to understand that it is just not one element that requires attention.

On the contrary, there are several factors that come into play. For instance, the material, features, thickness, function along with the capability of the prototyping manufacturer. It is vital to consider the die accuracy, along with the wear during the punching process.

You also need to pay heed to the fabrication process. After all, this process is majorly responsible for turning the sheet into prototypes and parts. The spacing between parts also has an impact on tolerance. So, the designers need to focus on this aspect as well.

Zero Clearance

If there is zero clearance between parts, it would lead to tolerance stack-up. Thus, it would lead to sheet parts finished, yet not matching the other parts during assembling. This is something that needs to be avoided at all costs.

Tooling Options

Tooling plays an important role, after all, they determine the shape of the sheet metal prototyping. For example, the straight-line bend is a common problem with conventional press-brake tolling. So, sheet-shaped using this tool ends up with the straight-line bends.

However, if you want to achieve the lowest cost, then a good idea is to constrain your design using this particular shape. Likewise, if you are interested in more detailed features, a good idea is to use the punch press.

It offers features like bridge lances, round embosses countersinks and many more. In the case of punch, we offer the standard sizes. Also, in terms of cost, these tools are the best option. When you choose experienced manufacturers such as the Essaii, you will have access to state of the art equipment.

Note: When you use the configuration of common tools, it would save you a lot of money in comparison to the part-specific tools.

Bends of Sheet Metal Prototyping

In sheet metal fabrication, bending holds great importance. Thank to modern and sophisticated technology, it is possible to turn flat sheet metal into a number of shapes. However, you do need to follow a certain set of rules to prevent flaws in the design of sheet metal bending parts.

Radius

It is extremely important to ensure that the radius of the inside bend is not more than the sheet metal’s thickness. Doing so will stop any sort of deforming in the future.

Consistent Bending Direction

Another rule that you really do to focus is to guarantee that the bending direction is consistent. With consistent bending direction, along with the correct bending radius, it is possible to cost fabrication. Also, the overall cost of making parts would come down.

Proper Bend Designing

Instead of relying on exclusive parts machines, it is a good idea to design bends while keeping in mind the standard forming process and tools. Doing this would ensure that the bends are cost-efficient as well as effective.

On the other hand, when you use specialized bending tools, it not only increases the cost significantly but also slows down the manufacturing process.

Neem weg

Following the above rules would improve the sheet metal prototyping design. Of course, a flawless design would lead to an error-less prototype and eventually to a successful product. However, to achieve this there are several factors that require consideration, robustness, weight, component assembling, and much more.

NOTE: If your sheet metal prototype is of a complex design, the above rules might not be effective.

In addition to focusing on all these elements, you also need to join hands with a reliable manufacturing partner. Essaii is among the leading steel metal prototype manufacturer. They will provide complete assistance from scratch. Their vast experience in the industry allows them to deliver high-quality, yet cost-efficient prototypes.

For further information, reach out to them on Essaii.