CNC Machining and Sheet Metal Prototyping

The company takes "honesty as the foundation" busines philosophy to provide users with professional and quality services.

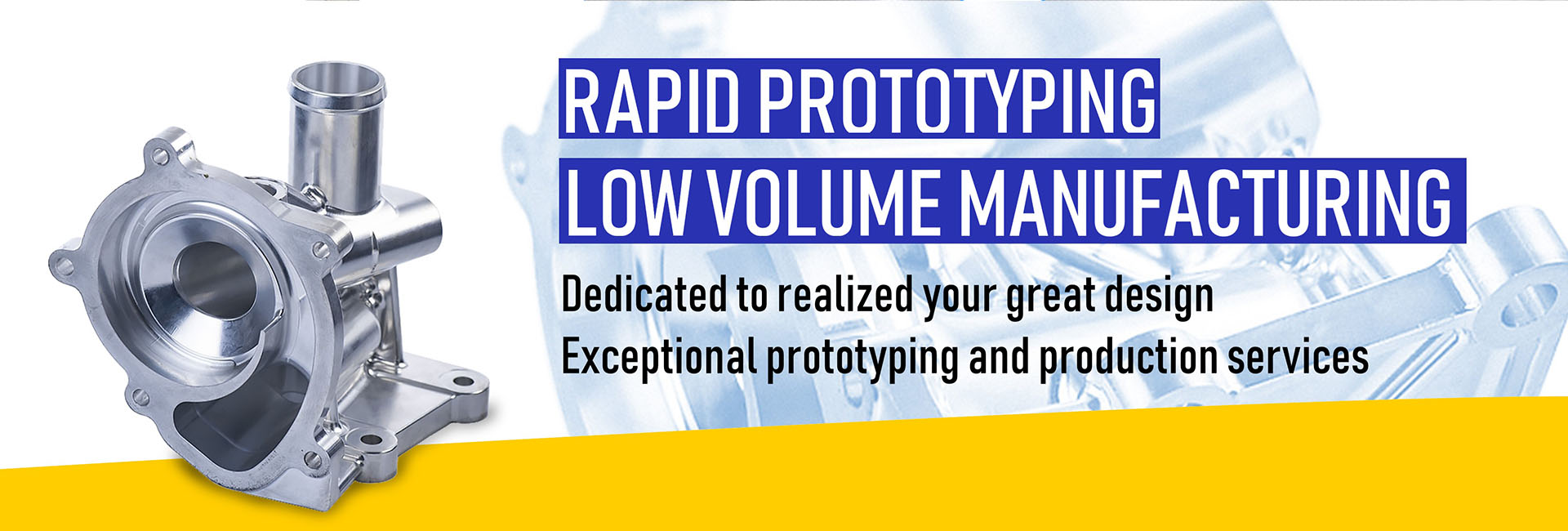

Rapid CNC machining is a new type of machining technology.

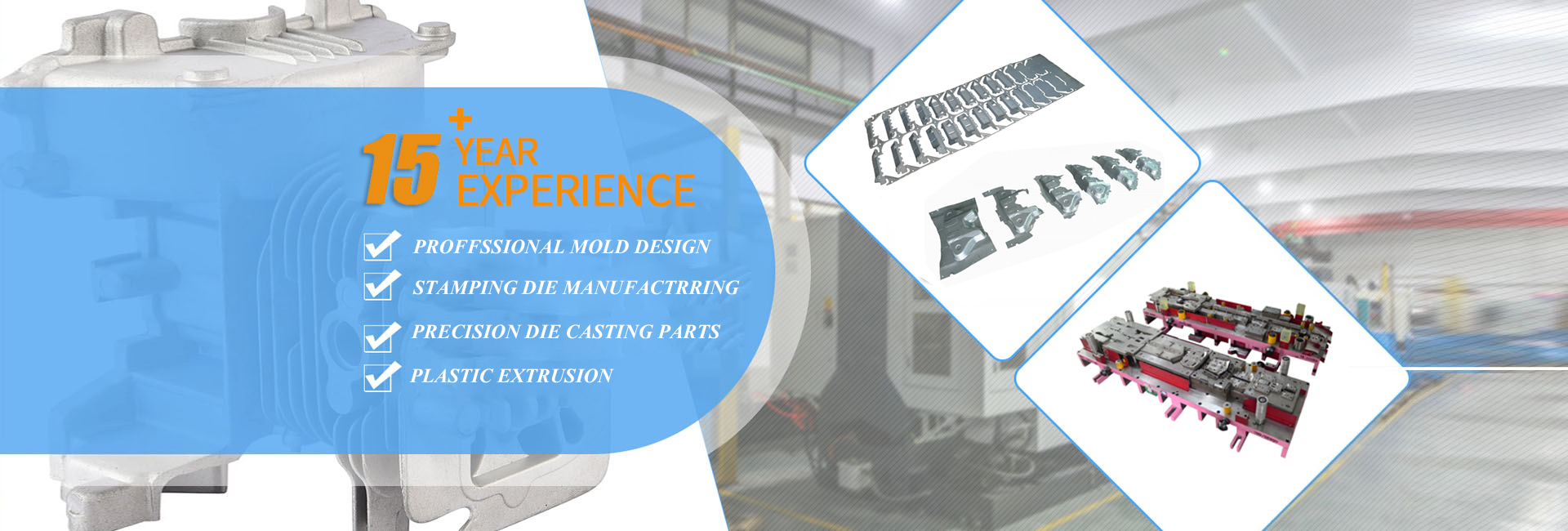

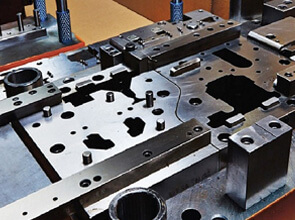

Die fabrication technology is the basis for the development of the mold industry.

Plastic Extrusion molding is an efficient, low-cost, wide-area molding processing method.

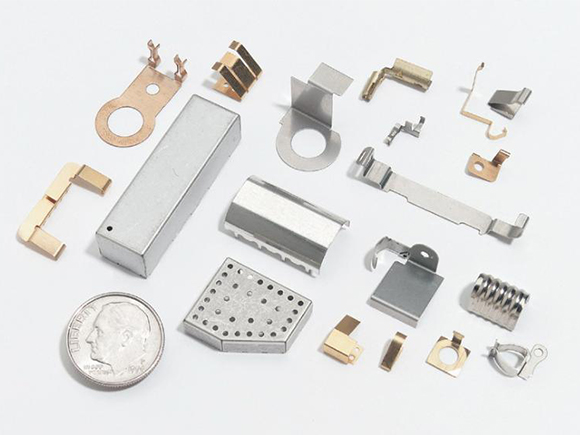

Sheet metal prototyping products are almost everywhere in our daily life.

ENGINEERING CASE

Provide technical hardware support for enterprises in various industries.

ABOUT ESSAI

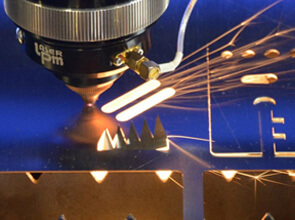

Established in 2006, Essai now offers an extensive manufacturing facility for the production of a wide variety of plastic & metal parts by means of injection moulding and tooling, die casting and tooling, sheet metal stamping & laser cutting, CNC machining, Metal Injection Moulding, plastic and metal extrusion, fabrication, assembly, painting, and printing, anodising, chrome plating and vacuum metalisation.

LATEST NEWS

Regularly update the technology and policy development trends of the electronics industry

VOICE FROM CUSTOMERS

CONTACT US

Tell us your project timeline or budget and let us find the most effective way to achieve your goals.

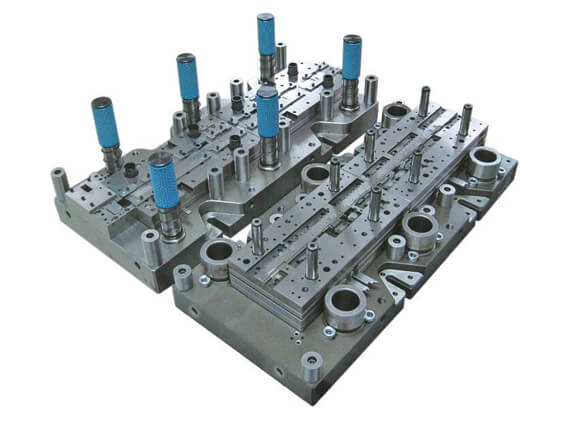

CNC metal parts

Computer Numerical Control (CNC) milling is a type of milling that uses computers to control the process. This basically means that instead of being moved and monitored by hand, the milling machine is moved and monitored by numerical computer control. CNC milling equipment use amazing precision to accomplish machining processes comparable to drilling and cutting items, leaving no space for human error. Because it can accept exact sizes and shapes of various types of materials, the method is becoming increasingly popular in industry.

The energy industry, as well as many other public-interest services, faces substantial problems as a result of the digital transition. Consistent and successful digital implementation of regulatory standards, technical possibilities, and consumer requirements can result in noticeable performance and quality improvements. Despite this, many stakeholders in the municipal and energy sectors have still not realized the benefits of end-to-end digitalization.

Essai, Inc. is a company that manufactures navigational, measuring, electromedical, and control instruments and is based in Fremont, California. Essai, Inc. employs 211 people throughout its many sites and generates $60.01 million in revenue (USD). (The sales figure is based on a simulation.) The Essai, Inc. corporate family consists of 63 firms.

At ESSAI, you'll find experts in digitalization strategy, new business models, process optimization, and system architecture who have real-world expertise. In the field of general interest services, our customers include the largest public utilities in Europe, the largest energy portfolios and network operators in Germany, as well as, of course, municipalities, energy groups, housing companies, service providers, technology suppliers, and software manufacturers.

CNC milling machines are extremely valuable in both commercial and industrial manufacturing. CNC Milling's products can help the aerospace, medical, and electronics industries.

How do CNC Milling Machines work?

A CNC Milling Machine transforms material into a vehicle or mechanical part by moving a spinning cylindrical cutter along many axes and creating slots, holes, and features in it. The majority of machines have three to five axes, which allows for far greater precision and detail. Both horizontal and vertical machining centres can be built into modern CNC milling machines. Plastics, ceramics, and composite materials, in addition to metals, can be used to construct components. Automatic tool changers, tool carousels and magazines, coolant systems, and enclosures are just a few of the technical characteristics that keep machines functioning efficiently without human intervention.

What are the different types of CNC Milling Machines?

The final output is significantly affected by the orientation of a CNC Milling Machine. A vertical mill is a common type of milling machine with a vertical spindle axis. Cutting tools on vertical CNC milling machines are typically long and thin, but cutting tools on horizontal CNC milling machines are often shorter and thicker.

Horizontal mills, on the other hand, are less adaptable and are better suited to long material work, such as cutting gears or machining axles.

Turret mills operate vertically, with no moving spindle, and a table that adjusts parallel and perpendicularly to perform the cutting operation. CNC Turret Milling Machines operate best when they're kept small, therefore they're perfect for fine work like making pieces for toys and plaques.

Turret Milling Machines and CNC Bed Mills are very similar. Nonetheless, because their lower table adjusts perpendicularly to conduct the cutting, they can be made larger than the Turret because their frame is sturdier. Bed mills are ideal for jobs like milling parts for mid-sized electronics that Turret mills couldn't handle because they have a larger structure.

How does a CNC Milling Machine benefit business?

Computer Numerical Control milling, as previously said, is extremely accurate. Turret mills, for example, can be programmed to execute complicated Rapid CNC Machining.

Essai specializes in quick prototyping, sheet metal fabrication, and small-batch custom part manufacture. Our multinational team of engineers and technicians employ cutting-edge technology and processes such as 3D metal printing, multi-axis CNC machining, and plastic injection molding to bring your ideas to life fast, correctly, and affordably.

We employ the most up-to-date software, advanced CNC machine tools, modern measuring equipment, and qualified technicians, as well as competitive quotes, quick delivery, and outstanding quality. Customers from all across the world have recognized Essai.

Production Capacity:

Essai can handle work pieces as little as a few millimeters in diameter up to sophisticated components like vehicle dashboards. Plastics and metal blanks, such as aluminum, stainless steel, carbon steel, PC, ABS, POM, and so on, are always in stock to satisfy a wide range of customer needs. We can also swiftly get more unusual materials for particular projects if necessary. The majority of Essai prototypes are made using CNC technology, which ensures accuracy comparable to or better than injection molding and allows customers to use their own materials to create their prototypes.

Associated post-treatment and surface treatment services, including as dusting and oxidation, are also available from Essai. Our metal CNC machining skills allow us to produce a wide range of parts in a variety of sizes for a variety of industries, including automotive, aerospace, marine, construction, scientific, and medical. We can make high-precision parts in small and big volumes using the most up-to-date CAD/CAM software and our experience processing most metals.

Advantages of the CNC machining:

Reduce the quantity of tools by a significant amount; complex items do not necessitate complicated tooling. If you'd like to alter the part's form and size. Only the part-processing programme needs to be changed. This is appropriate for the creation of new items and their modifications.

Processing quality is consistent, processing precision is excellent, and processing repeatability is high. It complies with the aircraft's processing needs.

The production efficiency is great in multi-variety and small batch manufacturing. They can cut down on the time it takes to prepare for production, change machine tools, and inspect processes. Due to the utilisation of the ideal cutting amount, the cutting time is reduced.

It's possible to connect many coordinates. Complex profiles that are difficult to process using traditional approaches can be processed with it. And it's even capable of digesting components that aren't visible.

When machining parts, changing the NC program is usually all that is required, saving time and money. The machine tool itself has high precision and rigidity. It can choose favorable processing volume and high productivity (generally 3 to 5 times that of ordinary machine tools).

High degree of machine tool automation can reduce labor intensity.

Our Services:

In CNC metal parts Essai provides following services

1) CNC Machine:

Three-Axis CNC

Four-Axis CNC

Five-Axis CNC

Turning CNC

Laser cutting

Sheet metal

2) Rapid Prototyping : 3D Printing / SLS / SLA/ Vacuum Casting

3) Silicon Compression

4) Low volume production and Assembly;

5) sheet metal part / stamping

Surface treatments:

Before the sample is ready to launch in the market, it is set to following treatments

Polishing, Painting, Anodizing, Electroplating , Sandblasting, silkscreen, Laser carving

We Served Industry:

Automotive, Home Appliance, Areospace, Consumer Electronic, Medical, Defence, Toy, ect.

Materials:

Material used for making the CNC is

1) Plastic - ABS, PMMA, PC, PP, PE, POM ect.

2) Metal - Aluminum, Stainless Steel, Brass, Zinc ect.

3) Others - Rubber, Silicon, ect.