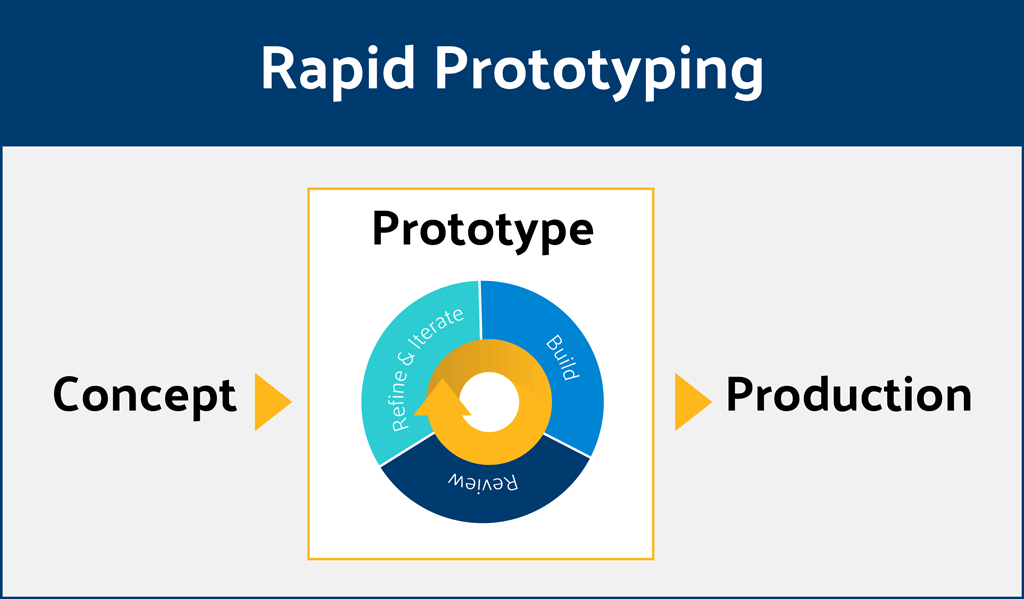

Professional rapid prototyping 2020: How does rapid prototype work?

2020-07-20An Ultimate Guide to Understand Rapid prototyping working for beginners

What is Professional rapid prototyping?

Professional rapid prototyping is basically a key for the success of any type of business or company.

Engineers agree that without prototyping, it is not possible to fabricate the best quality products. For the purpose of research and to make advanced development in your products, prototyping is an essential process. And rapid prototyping is the fastest way to meet your needs.

In today's fast paced and competitive world it is necessary to create your product development process faster like never before. And without rapid prototyping you can never achieve this goal.

What is the role of 3D printing in prototyping?

النماذج الأولية السريعة is actually the rapid and quick creation of a physical model, part or assembly. And للنماذج الأولية السريعة الاحترافية uses 3D computer-aided design (CAD) in its manufacturing. Manufacturers use 3D printing or additive manufacturing process in fabricating of the model, part or assembly.

in rapid prototyping, the created design thoroughly matches the final design of the product. Furthermore, engineers accept that a rapid prototype is a great allegiance type of prototype. But there is an obvious difference between the final product and low allegiance type of prototype.

Engineers admit that among all prototyping process rapid prototyping is best in all conditions. And it is a fact that rapid prototyping is more popular because of its lesser amount of time.

But maybe there is a question in your mind that what is للنماذج الأولية السريعة الاحترافية in fact? Here is a complete guidance for you in order to provide you information about a successful project of rapid prototyping.

Which type of material and technology is important for Professional rapid prototyping?

If you have decided to rapid prototyping with the use of 3D printing, then you generally have distinct choices of technology and material. And it totally depends on the kind of prototype you want to fabricate. There are certain conditions for rapid prototyping.

If you have made decision to fabricate initial or earlier prototype. Then never waste your money and time to invest more on the visible quality of your desired material.

Actually, you are only testing that the shape of your product is satisfactory or not. Hence for this purpose, you should use quite cheaper material for للنماذج الأولية السريعة الاحترافية. And never try to waste extra on this step. For this purpose, expert engineers use raw Nylon PA12.

So, it has suggested as a best material because it is a terrific choice. Because technology of Selective Laser Sintering has used for this raw material. But in the condition to obtain a prototype with the quality of good surface. We suggest you to choose the material that normally matches to your final or last material.

How does للنماذج الأولية السريعة الاحترافية work?

There are variety of manufacturing technologies which engineers use in rapid prototyping. Even though engineers use here bulk of additive manufacturing of utilize layered. But other technologies use for للنماذج الأولية السريعة الاحترافية are:

- casting

- high-speed machining

- extruding

- moulding

But engineers mostly use the additive manufacturing process for fabricating rapid prototypes. Furthermore, there are also some extra conventional procedures that engineers make use to produce good prototypes.

What are some of the advantages of للنماذج الأولية السريعة الاحترافية ؟

There are lot of advantages of Professional rapid prototyping. We are describing some of them here.

These advantages are:

- Ability to explain the final design

- Ability of several changes

- Cost efficient

- Quality of visual effects

- Choice and flexibility

Complete description about each of the above advantage of للنماذج الأولية السريعة الاحترافية

Ability to explain the final design:

A good prototype has the quality to display a complete and perfect figure of the final product. And it also has the ability to explain that how your final design of product will perform. It will show its performance during several cycles of manufacturing. It also has capability to improve the design.

Ability of several changes:

Furthermore, it holds the capacity to allow the design for several changes in the early process as well as at any stage of the final design. Time limits for this type of prototype vary from days to months. It usually depends on the methods which engineers use in للنماذج الأولية السريعة الاحترافية.

Cost efficient:

بغرض إنشاء نماذج أولية لمنتجاتك ، تعد RP أيضًا فعالة من حيث التكلفة. علاوة على ذلك ، فهي عملية تلقائية وبالتالي ليست هناك حاجة لتشغيلها مرارًا وتكرارًا. نظرًا لأن هذه العملية تستخدم التصميم بمساعدة الكمبيوتر (CAD) ، فهي تؤمن وتقلل من هدر المواد.

علاوة على ذلك ، ليست هناك حاجة أيضًا إلى بعض الأدوات الخاصة لعمل نموذج أولي لكل منتج جديد أو جديد.

علاوة على ذلك ، نحن نقدم تفاصيل حول بعض السمات المميزة للنماذج الأولية السريعة الاحترافية

جودة المؤثرات البصرية:

كما ترشد النماذج الأولية السريعة مستخدميها ومصمميها إلى ابتكار أفكار جديدة. يساعد المهندسين على إبراز مفاهيمهم وأفكارهم المتقدمة أمام ما يلي:

- العملاء

- أعضاء مجلس الإدارة

- المستثمرين

Hence, they can easily reach their target product. The process of Professional rapid prototyping has also the ability to visual effects, so that customers can easily understand the physical parts of their final designs. Hence, it is better than a concept because it has the final existence.

Choice and flexibility:

Engineers know that RP is a repetitive procedure. And has the capability to allow its customers to feedback about its final product. RP methods allows its customers and users to design and add changes in the final product.

Hence, it has great flexibility for the design and as well as for customers. It makes changes according to the demands of the customers and for target design. And also gives many choices and flexibilities to their users to reach their needs.

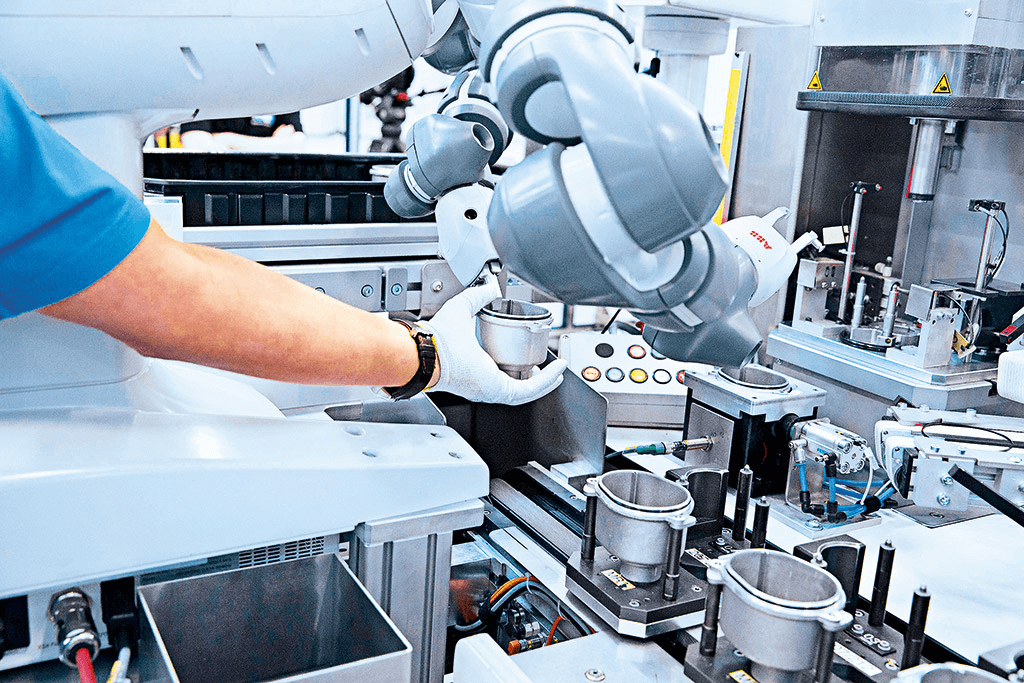

ما هي تطبيقات للنماذج الأولية السريعة الاحترافية ؟

يستفيد المهندسون والمصممون من للنماذج الأولية السريعة الاحترافية لتصنيع النماذج الأولية بسرعة. يمكن أن يساعد في تصنيع النماذج الأولية بالطرق التالية:

- التصميم

- التصور

- تطوير

في الأساس ، تم استخدام RP لأول مرة من أجل إنتاج ما يلي:

- مقاييس

- القطع

لصناعة السيارات. لكن المهندسين الآن يستخدمونها في كل صناعة معقدة مثل:

- الفضاء

- طبي

لماذا يفضل المهندسون صب الألمنيوم في للنماذج الأولية السريعة الاحترافية ؟

يفضل المهندسون صب الألمنيوم في RP. نظرًا لوجود استخدام واسع للألمنيوم في كل التطبيقات والأشياء تقريبًا.

Similarly, aluminum has the ability to make the raw material most durable and tough. Even though it is not as durable as iron but it is relatively strong and low cost for a huge production run.

Furthermore, aluminum cast in the process of للنماذج الأولية السريعة الاحترافية can half the spend in comparison to any other metal. It is all because of the lightweight qualities of aluminum metal.

Moreover, it also helps the engineers to fabricate rapid prototypes quite easily. Because aluminum metal has great flexibility to cut and fabricate the final designs in the form of rapid prototypes.