أفضل 10 ممارسات لجزء بثق الألمنيوم وتصنيع الألمنيوم في عام 2020

2020-07-24المشاكل واستكشاف الأخطاء وإصلاحها مع أجزاء بثق الألومنيوم وتصنيع الألومنيوم

جزء بثق الألومنيوم وتصنيع الألومنيوم مقدمة

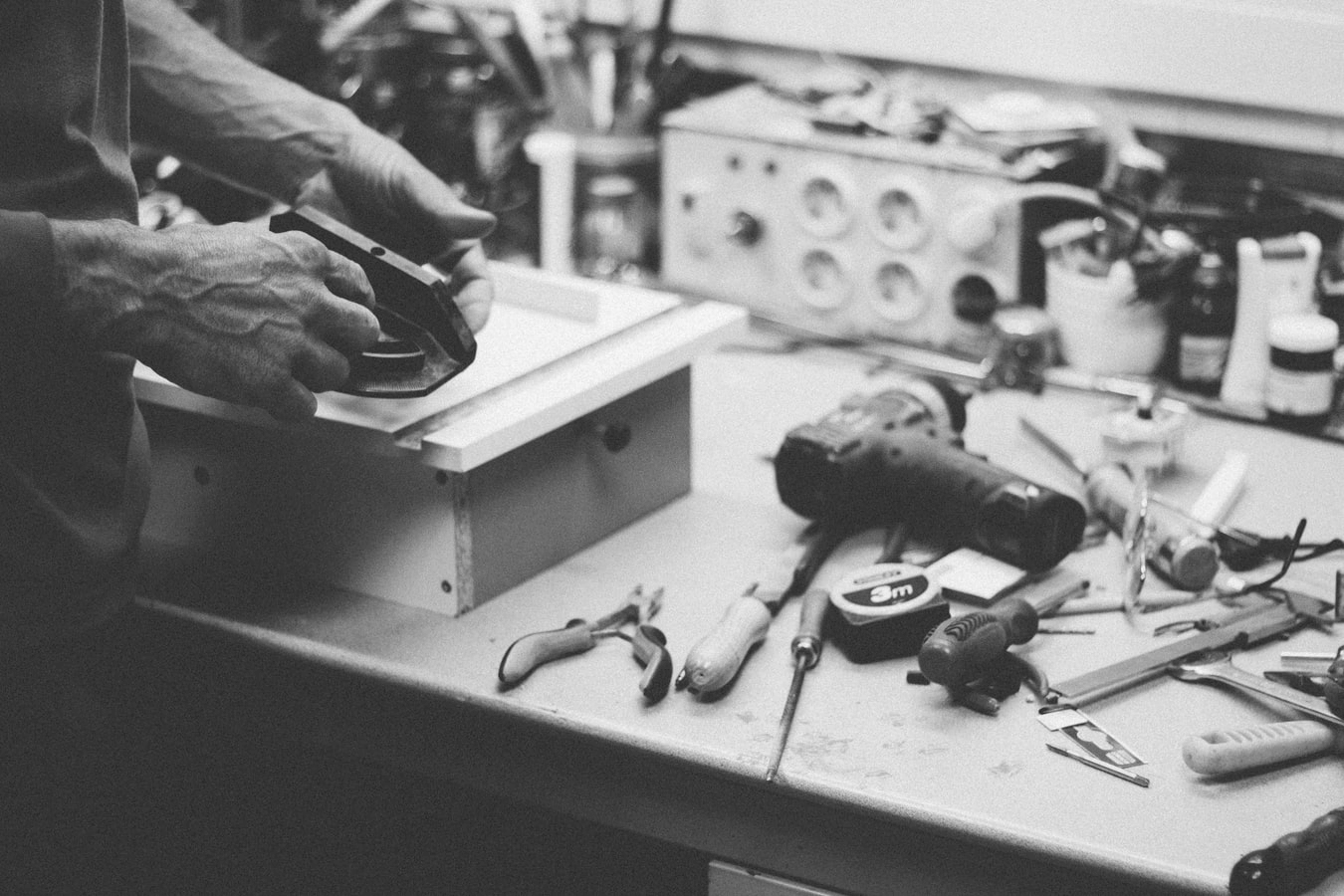

هل أنت من عشاق الأعمال اليدوية (DIY) وتعمل بمواد مختلفة ، وخاصة الألومنيوم؟ باستخدام هذا النوع من مواد البناء ، يمكنك تحقيق أشكال مختلفة مثل الأنبوب والمسطحة والعديد من الأشكال الأخرى. يتم الحصول على هذه الأشكال المختلفة من بثق الألومنيوم وتصنيع الألومنيوم ، وهو مفهوم التصنيع الميكانيكي أو الإنشاء.

This is the compression of a material which is forced to pass through a die with the shape of the part to be created. The result obtained is cleaner, more precise and does not require any modification.

Obtaining this perfect result no longer requires technicians to resort to machining parts. However, it is good to know that جزء بثق الألومنيوم وتصنيع الألومنيوم can be used in other products. Such as:

- Metals

- Plastics

- Composites

- clay, but also pasta

This process is also found in the pharmaceutical field for the manufacture of medicaments such as pills.

What is Aluminum Extrusion & Aluminum machining part?

جزء بثق الألومنيوم وتصنيع الألومنيوم is a process by which the metal, originally in billet form, is pushed under high pressure.

The extrusion of aluminum alloys can be done cold in the case of alloys with low mechanical strength and high ductility. Moreover, aluminum alloys are considered to be the most suitable materials for extrusion.

Similarly, they are distinguished by a variety of profiles unmatched compared to other materials.

جزء بثق الألومنيوم وتصنيع الألومنيوم is a mechanical manufacturing process consisting in compressing a material into a given format under the action of pressure. Extrusion can be carried out hot or cold and can be combined with a chemical or enzymatic reaction.

Generally, in this case we speak of reactive extrusion. It produces long shapes, with a flat or hollow section. Subsequently, a very large number of materials can be extruded:

- معدن

- Plastic

- rubber

- ceramics

- textile fiber

- pulp ...

جزء بثق الألومنيوم وتصنيع الألومنيوم : examples of applications

- Food industry:

Simple جزء بثق الألومنيوم وتصنيع الألومنيوم is used to make pasta and some cookies. Cooking-extrusion combines mixing, shearing and compression operations which heat food, which produces “cooking” and evaporation of water.

This technique not only changes the structure and composition of foods, but also their functional and nutritional properties.

It is used for the manufacture of:

- breakfast cereals

- confectionery

- “cracotte” type pancakes

- infant flour

- aperitif snacks

- processed cheese

Extrusion cooking is also used for the texturing of proteins or the production of bioplastic by modification of thestarch.

- Plastics:

The plastic is introduced into an extruder in the form of granules. The machine heats the granules which melt to give a homogeneous plastic paste. It will then be "blown" or molded through the extrusion head. We thus obtain products of different shapes:

- Cups

- cans and

- containers

- cables

- PVC sheaths

- blinds ,

- pipes, plastic profiles , toys, signs ...

Metallurgy:

Aluminum Extrusion & Aluminum machining part makes it possible to obtain long pieces of metal with complex section shapes. Such as:

- aluminum profiles for automotive

- industry or construction

Given that obtaining long profiles with complex shapes with good mechanical resistance. They are in great demand by the market. It is done essentially by hot جزء بثق الألومنيوم وتصنيع الألومنيوم . This process will be dealt with exclusively in what follows.

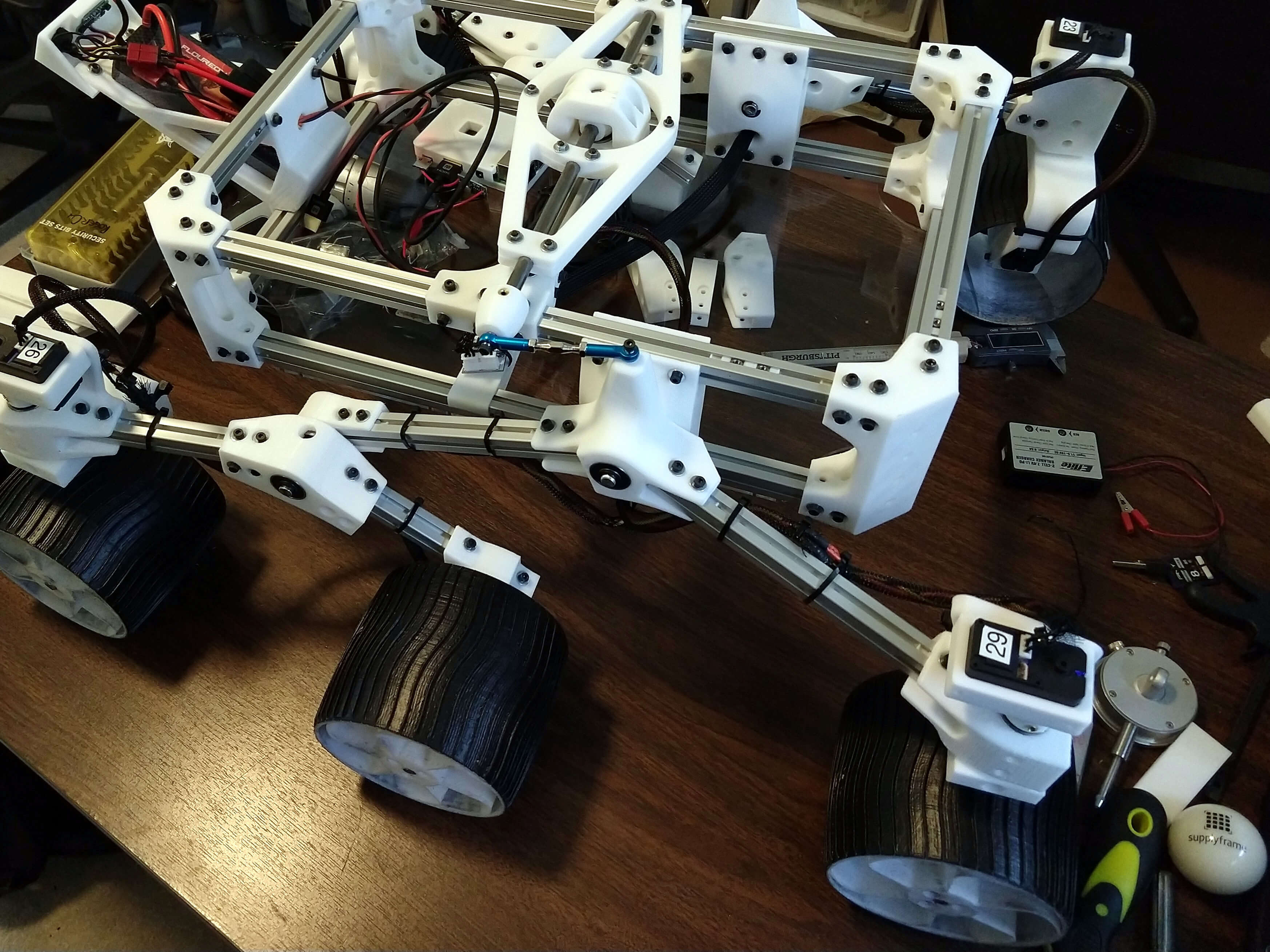

By the extrusion process, a long product is obtained with a constant cross section over its entire length. The section is generally more complex than that of a bar or tube. Depending on the shape of its cross section, it is called a solid, semi-hollow, or hollow profile.

جزء بثق الألومنيوم وتصنيع الألومنيوم is a means of shaping which is not unique to aluminum. But this metal is the only one whose formability allows obtaining structural resistance profiles with very elaborate shapes that meet specific needs.

This is what makes extrusion very attractive to many processors. There are many functions that can be incorporated when designing a product made from extrusions.

جزء بثق الألومنيوم وتصنيع الألومنيوم methods

There are two hot extrusion methods:

Direct Extrusion (Forward): The piston moves in the same direction as the extruded section, causing the billet to move relative to the container.

Indirect Extrusion (backward): The plunger is pushed against the billet in the opposite direction to that of the output of the profile. The billet remains stationary in the container.

Direct جزء بثق الألومنيوم وتصنيع الألومنيوم هو أبسط طريقة للإنتاج ويمكن أن يتم بدون تزييت. وبالمثل ، فإن البثق المباشر يجعل من الممكن حصر الأكاسيد الموجودة في البداية على سطح البليت في نهاية الملف الشخصي.

ويهدف إلى إنتاج منتج بسطح جميل. من ناحية أخرى ، يتميز البثق غير المباشر بميزة تتطلب حمولة قصوى تتراوح من 25 إلى 30٪ من البثق المباشر لإنتاج الحد الأدنى من الحرارة والاحتكاك.

العوامل المؤثرة في جزء بثق الألومنيوم وتصنيع الألومنيوم process

سرعات البثق ودرجة الحرارة

The temperature developed during جزء بثق الألومنيوم وتصنيع الألومنيوم has a great influence on the speed of the process. Especially in the case of aluminum alloys with high mechanical strength.

Aluminum alloy billets are generally heated between 350 and 500 ° C at the press entrance. During extrusion, the temperature of the material is affected by several factors. These phenomena occur simultaneously which explains the complex relationship that exists between the material to be extruded and the process parameters. Such as:

- billet temperature

- friction

- temperature and

- tool material

Problems and Troubleshooting with جزء بثق الألومنيوم وتصنيع الألومنيوم

Superficial cracks

الأسباب المحتملة : سرعة بثق عالية جدًا أو احتكاك شديد أو درجة حرارة عالية جدًا. في درجات حرارة منخفضة للغاية ، الانزلاق اللاصق تشققات.

شقوق داخلية

الأسباب : تحدث هذه العيوب في ظل ظروف انخفاض الاحتكاك وانخفاض معدل البثق. يمكن أن تؤدي زاوية القالب الكبيرة ، فضلاً عن النسبة العالية من الطول وطول منطقة الإجهاد (h / L) ، إلى تعزيز هذه العيوب.

عصابات أكسيد داخلية

الأسباب : في تجانس التشوه يتسبب في سحب الأكاسيد الموجودة على سطح الحبيبات باتجاه المركز.

الحلول المقترحة : تقليل الاحتكاك واختلاف درجة الحرارة بين مركز ومحيط القضيب.

بثق الألمنيوم وجزء تصنيع الألمنيوم والبناء

The majority of construction companies now use this new system since it allows obtaining impeccable results. These professionals can have doors and windows made in different styles at the customer's request.

Resorting to the use of aluminum is the safest. Because it is an easy material to work and it does not weigh heavy. It should be noted that aluminum is a malleable metal that is very resistant to oxidation.

According to scientific studies, it is the metal that is found in abundance in the earth's crust after oxygen and silicon. With its silver color, it can be integrated anywhere and go well with all colors and other materials. T

The products obtained from the Aluminum machining part are also used in the manufacture of reinforcement for reinforced concrete and the various accessories that compose it.

Products obtained from aluminum

There are many things that can be made from aluminum extrusion other than building materials. Some car manufacturers use it for the manufacture of mechanical parts, bodywork, rims, roll bars, etc.

It is also used in making furniture home such as tables, cabinets, and also for the manufacture of stairs and various media. Of all the existing building materials, aluminum is the most widely used.

There are many reasons for this choice, such as its price which is very attractive. Moreover, it is very light weight, and its handling. Aluminum is very decorative and this is also the reason why some designers use it as a raw material today.

Where to find an Aluminum Extrusion & Aluminum machining part professional?

In recent years, several aluminum Extrusion & Aluminum machining part professionals have embarked on this field since it is a type of market that pays a lot. Similarly, aluminum is present everywhere and the risk of shortage is still very far away.

However, some of these manufacturers of objects obtained by extrusion boycott the quality of their achievements. The later only think about liquidating their product and no longer pay attention to the small details.

Finding a true professional can be easy, just look back on their accomplishments and years of experience in the field.

How aluminum extrusion products are manufactured?

Aluminum and aluminum alloy semi-finished products are produced by rolling or extrusion. Simultaneously, these are the two main shaping processes. Global consumption of semi-finished products is approximately 50% of total consumption. That of spun semi-finished products is around 25%.

Aluminum Extrusion & Aluminum machining part Conclusion

Aluminum Extrusion makes it possible to obtain profiles with very varied sections and shapes, solid, hollow or semi-hollow. It is an essential factor in technological progress due to the number of new technical solutions that it allows.

The profile of aluminum is experiencing growing applications in the most diverse industrial sectors: transport, construction, aeronautics, etc.

تطور يفسر بخصائصه الميكانيكية العظيمة للمقاومة والخفة ، ومقاومته للتآكل. بالإضافة إلى ذلك ، جزء بثق الألومنيوم وتصنيع الألومنيوم أمرًا حيويًا.