10 Best Practices for Aluminum Extrusion & Aluminum machining part in 2020

2020-07-24Problems and Troubleshooting with Aluminum Extrusion & Aluminum machining parts

Aluminium-Extrusions- und Aluminium-Bearbeitungsteil Introduction

Are you a DIY enthusiast and you work with various materials, especially aluminum? With this type of building material, you can achieve different shapes such as tube, flat and many more shapes. These various shapes are obtained from aluminum Extrusion & Aluminum machining part, a concept of mechanical manufacturing or creation.

This is the compression of a material which is forced to pass through a die with the shape of the part to be created. The result obtained is cleaner, more precise and does not require any modification.

Obtaining this perfect result no longer requires technicians to resort to machining parts. However, it is good to know that Aluminium-Extrusions- und Aluminium-Bearbeitungsteil can be used in other products. Such as:

- Metals

- Kunststoffe

- Composites

- clay, but also pasta

This process is also found in the pharmaceutical field for the manufacture of medicaments such as pills.

What is Aluminum Extrusion & Aluminum machining part?

Aluminium-Extrusions- und Aluminium-Bearbeitungsteil is a process by which the metal, originally in billet form, is pushed under high pressure.

The extrusion of aluminum alloys can be done cold in the case of alloys with low mechanical strength and high ductility. Moreover, aluminum alloys are considered to be the most suitable materials for extrusion.

Similarly, they are distinguished by a variety of profiles unmatched compared to other materials.

Aluminium-Extrusions- und Aluminium-Bearbeitungsteil is a mechanical manufacturing process consisting in compressing a material into a given format under the action of pressure. Extrusion can be carried out hot or cold and can be combined with a chemical or enzymatic reaction.

Generally, in this case we speak of reactive extrusion. It produces long shapes, with a flat or hollow section. Subsequently, a very large number of materials can be extruded:

- Metal

- Plastic

- rubber

- ceramics

- textile fiber

- pulp ...

Aluminium-Extrusions- und Aluminium-Bearbeitungsteil : Anwendungsbeispiele

- Nahrungsmittelindustrie:

Ein einfaches Aluminium-Extrusions- und Aluminium-Bearbeitungsteil wird verwendet, um Nudeln und einige Kekse herzustellen. Die Kochextrusion kombiniert Misch-, Scher- und Kompressionsvorgänge, bei denen Lebensmittel erhitzt werden, wodurch Wasser gekocht und verdampft wird.

Diese Technik verändert nicht nur die Struktur und Zusammensetzung von Lebensmitteln, sondern auch deren funktionelle und ernährungsphysiologische Eigenschaften.

Es wird zur Herstellung von:

- Frühstücksflocken

- Süßwaren

- Pfannkuchen vom Typ "Cracotte"

- Säuglingsmehl

- Aperitif Snacks

- Schmelzkäse

Das Extrusionskochen wird auch zur Texturierung von Proteinen oder zur Herstellung von Biokunststoff durch Modifikation der Stärke verwendet.

- Kunststoffe:

The plastic is introduced into an extruder in the form of granules. The machine heats the granules which melt to give a homogeneous plastic paste. It will then be "blown" or molded through the extrusion head. We thus obtain products of different shapes:

- Cups

- cans and

- containers

- cables

- PVC sheaths

- blinds ,

- pipes, plastic profiles , toys, signs ...

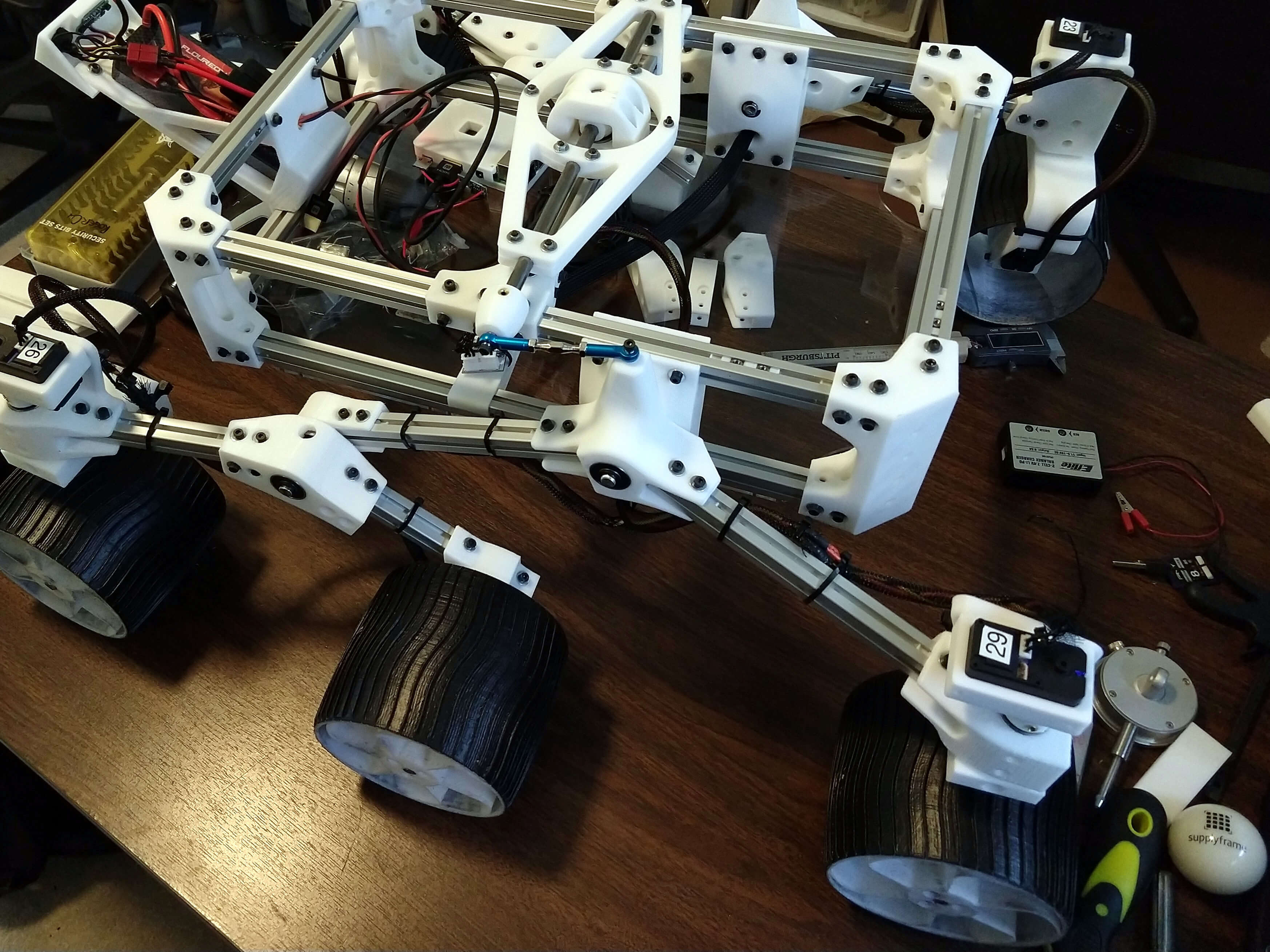

Metallurgy:

Aluminum Extrusion & Aluminum machining part makes it possible to obtain long pieces of metal with complex section shapes. Such as:

- aluminum profiles for automotive

- industry or construction

Given that obtaining long profiles with complex shapes with good mechanical resistance. They are in great demand by the market. It is done essentially by hot Aluminium-Extrusions- und Aluminium-Bearbeitungsteil . This process will be dealt with exclusively in what follows.

By the extrusion process, a long product is obtained with a constant cross section over its entire length. The section is generally more complex than that of a bar or tube. Depending on the shape of its cross section, it is called a solid, semi-hollow, or hollow profile.

Aluminium-Extrusions- und Aluminium-Bearbeitungsteil is a means of shaping which is not unique to aluminum. But this metal is the only one whose formability allows obtaining structural resistance profiles with very elaborate shapes that meet specific needs.

This is what makes extrusion very attractive to many processors. There are many functions that can be incorporated when designing a product made from extrusions.

Aluminium-Extrusions- und Aluminium-Bearbeitungsteil methods

There are two hot extrusion methods:

Direct Extrusion (Forward): The piston moves in the same direction as the extruded section, causing the billet to move relative to the container.

Indirect Extrusion (backward): The plunger is pushed against the billet in the opposite direction to that of the output of the profile. The billet remains stationary in the container.

Direct Aluminium-Extrusions- und Aluminium-Bearbeitungsteil is the simplest mode of production and can be done without lubrication. Likewise, direct extrusion makes it possible to confine the oxides initially present on the surface of the billet at the end of the profile.

And it aims to produce a product with a beautiful surface finish. Indirect extrusion, on the other hand, has the advantage of requiring a maximum load of 25 to 30% of that of direct extrusion of producing minimal heat and friction.

Parameters affecting the Aluminium-Extrusions- und Aluminium-Bearbeitungsteil process

Extrusion speeds and temperature

Die Temperatur, die während der Aluminiumextrusion und der Aluminiumbearbeitung entwickelt wird, hat einen großen Einfluss auf die Geschwindigkeit des Prozesses. Besonders bei Aluminiumlegierungen mit hoher mechanischer Festigkeit.

Knüppel aus Aluminiumlegierungen werden in der Regel am Eingang der Presse zwischen 350 und 500 ° C erhitzt. Während der Extrusion wird die Temperatur des Materials von mehreren Faktoren beeinflusst. Diese Phänomene treten gleichzeitig auf, was die komplexe Beziehung zwischen dem zu extrudierenden Material und den Prozessparametern erklärt. Sowie:

- Knüppeltemperatur

- Reibung

- Temperatur und

- Werkzeugmaterial

Probleme und Fehlerbehebung mit Aluminium-Extrusions- und Aluminium-Bearbeitungsteil

Oberflächliche Risse

Mögliche Ursachen : Zu hohe Extrusionsgeschwindigkeit, zu viel Reibung oder zu hohe Temperatur. Bei sehr niedrigen Temperaturen kann das Stick-Slip- Phänomen Risse verursachen.

Innenrisse

Ursachen : Diese Defekte treten unter Bedingungen geringer Reibung und geringer Extrusionsrate auf. Ein großer Düsenwinkel sowie ein hohes Verhältnis von Höhe und Dehnungszonenlänge (h / L) können diese Defekte fördern.

Innere Oxidbanden

Ursachen : In Homogenität der Verformung ziehen sich die auf der Oberfläche des Knüppels vorhandenen Oxide zur Mitte hin.

Lösungsvorschläge : Reduzieren Sie die Reibung und den Temperaturunterschied zwischen der Mitte und dem Umfang des Knüppels.

Aluminium Extrusion & Aluminium Bearbeitungsteil und Konstruktion

The majority of construction companies now use this new system since it allows obtaining impeccable results. These professionals can have doors and windows made in different styles at the customer's request.

Resorting to the use of aluminum is the safest. Because it is an easy material to work and it does not weigh heavy. It should be noted that aluminum is a malleable metal that is very resistant to oxidation.

According to scientific studies, it is the metal that is found in abundance in the earth's crust after oxygen and silicon. With its silver color, it can be integrated anywhere and go well with all colors and other materials. T

The products obtained from the Aluminum machining part are also used in the manufacture of reinforcement for reinforced concrete and the various accessories that compose it.

Products obtained from aluminum

There are many things that can be made from aluminum extrusion other than building materials. Some car manufacturers use it for the manufacture of mechanical parts, bodywork, rims, roll bars, etc.

It is also used in making furniture home such as tables, cabinets, and also for the manufacture of stairs and various media. Of all the existing building materials, aluminum is the most widely used.

There are many reasons for this choice, such as its price which is very attractive. Moreover, it is very light weight, and its handling. Aluminum is very decorative and this is also the reason why some designers use it as a raw material today.

Where to find an Aluminum Extrusion & Aluminum machining part professional?

In recent years, several aluminum Extrusion & Aluminum machining part professionals have embarked on this field since it is a type of market that pays a lot. Similarly, aluminum is present everywhere and the risk of shortage is still very far away.

However, some of these manufacturers of objects obtained by extrusion boycott the quality of their achievements. The later only think about liquidating their product and no longer pay attention to the small details.

Finding a true professional can be easy, just look back on their accomplishments and years of experience in the field.

How aluminum extrusion products are manufactured?

Aluminum and aluminum alloy semi-finished products are produced by rolling or extrusion. Simultaneously, these are the two main shaping processes. Global consumption of semi-finished products is approximately 50% of total consumption. That of spun semi-finished products is around 25%.

Aluminum Extrusion & Aluminum machining part Conclusion

Aluminum Extrusion makes it possible to obtain profiles with very varied sections and shapes, solid, hollow or semi-hollow. It is an essential factor in technological progress due to the number of new technical solutions that it allows.

The profile of aluminum is experiencing growing applications in the most diverse industrial sectors: transport, construction, aeronautics, etc.

A development explained by its great mechanical qualities of resistance and lightness, its resistance to corrosion. In addition, Aluminiumextrusion und der Aluminiumbearbeitung entwickelt wird, durability is vital.