차갑고 뜨거운 금속 스탬핑이란 무엇입니까? 판금 스탬핑을 만드는 방법?

2020-07-21금속 스탬핑 프레스를 이해하기위한 실용적인 가이드

The topic of 금속에모든 시대에 인기를 끌었습니다. 현대 기술과 관련하여 특히 유명합니다. 그러나 실제로 금속 스탬핑의 은 수세기에 걸쳐 진보 된 기술이 된 고대 공예품입니다.

금속 스탬핑이란 무엇입니까?

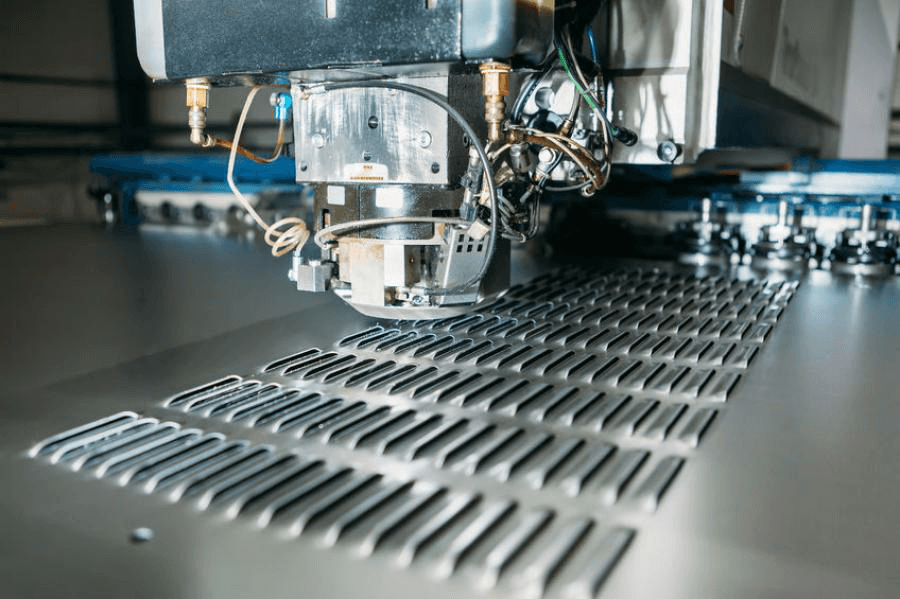

금속 스탬핑 is a controlled deformation process in which the body changes its shape under the influence of excessive pressure. Thanks to such processing, metal products are given the most diverse forms that they need to fulfill their functional duties.

Stamping gives in to parts of small thickness, since bending thick products is very problematic.

How metal stamping is carried out?

Metal stamping allows you to quickly and accurately shape the original sheet material into a finished product.

This process consists in the deformation of the metal under the action of directional pressure. In this case, the material changes its shape, while maintaining the initial thickness of the sheet.

The main types of metal stamping

This method of processing is used in small, medium and large volumes in industries.

Stamping of metal products is used in almost all industries. Moreover, it allows you to create any kind of detail. This technology has a very long history and is now actively developing.

New methods are constantly emerging that use forces of different origins other than gravity. Similarly, deformation occurs under the influence of:

- hydraulic pressure

- electric current

- Magnetic field, etc.

Next, we will consider issues related to the principle of operation of:

- 금속 스탬핑의

- types and

- methods of metal deformation

- The use of products created in this way in various industries.

What is sheet metal deformation?

Deformation of sheet metal can be carried out under the influence of high pressure. Based on this, all types of stamping can be divided into two large groups:

- cold;

- hot

Generally, both types have advantages and disadvantages that delimit the scope of their use. Cold stamping is carried out at a temperature below the melting point of the metal.

Furthermore, this avoids shrinkage during cooling. But it imposes restrictions on the shape of the final product. This method creates parts without a large number of embossed elements, for example, parts of a car body.

The main requirements for the material used during cold 금속 스탬핑의 are high ductility. In addition, the method is suitable for:

- low-carbon and alloy steels

- 구리

- Brass

- aluminum and magnesium alloys, and

The following is required for metal stamping:

- A soft pad, a metal foil and embossing tool.

- If you want to try out the technique first, you can use a simple embossing pen and a teaspoon as a tool.

- If you like this hobby then you should get the right tools. It is much easier to achieve much, much better results.

- The special 금속 스탬핑의 tools look a bit "old-fashioned". But also very stable - and that's exactly what they are! They serve their purpose better than some new tools. Because they are stable and fit well in the hand.

Why metal stamping?

금속 스탬핑 is an important manufacturing process, depending on what stamping requires shape and function. The advantages are:

- high production rate

- consistency and

- Low cost.

금속 스탬핑 technology is applied in many industries. Such as:

- 자동차

- heavy industry

- electronic industries

- electronic components

- hardware accessories

- Vehicle accessories.

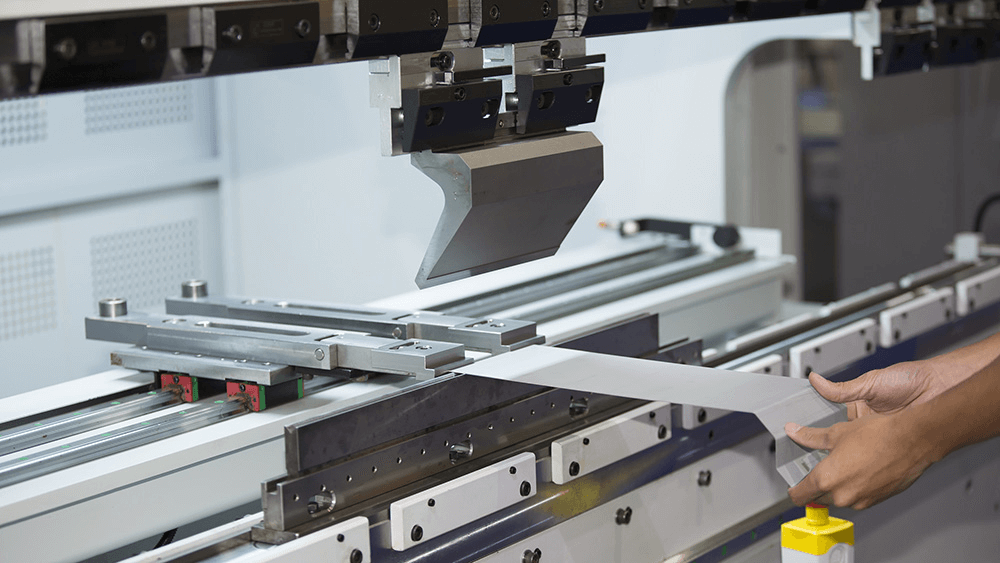

스탬핑 성형 기술은 기술을 결합하여 원하는 모양을 형성하는 기술입니다. 예 :

- 굽힘

- 그림

- 펀칭 및

- 금속판 재료 절단.

저비용으로 다량의 제품을 생산할 수있는 장점이 있습니다. 금속 부품 제조의 주요 기술 중 하나입니다.

단조에 사용되는 주요 기계식 해머

현대 단조 기계에는 주로 기계식 해머와 프레스 기계가 포함됩니다.

첫째, 단조에 사용되는 두 가지 주요 유형의 기계식 해머가 있습니다.

- 에어 해머

- 스프링 해머

유압 금속 스탬핑이란 무엇입니까?

유압 프레스는 물이나 기름이 공급되는 실린더의 압력을 사용하여 가공을 수행하는 프레스 기계입니다. 실린더에 전달되는 유압을 조정하여 부하와 속도를 제어 할 수 있습니다.

차가운 시트의 잠재적 인 금속 스탬핑

판금 금속 스탬핑의 및 성형은 라미 나에서 시작하여 물체와 금속 제품을 만들 수있는 생산 공정입니다. 도구 유형에 따라 다양한 모양과 크기로 압축되고 성형됩니다.

이 시트는 가구에서 전자 제품, 물체에서 난방, 식품에서 산업 분야에 이르기까지 많은 분야에 적용됩니다.

시트를 스탬핑하면 저렴한 비용으로 고품질의 물체를 생산할 수 있습니다. 모양과 특성이 매우 정교하고 세부 사항이 풍부한 경우에도.

이는 생산 및 생산 공정에 사용되는 기계가 모든면에서 매우 정교하고 최첨단이기 때문입니다.

The fastest and most efficient sheet metal pressing technique is the cold one. Let's look at how it works.

What is cold stamping of sheet metal?

The cold sheet is the most convenient and rapid type of industrial molding. Because it is operated at ambient temperature, without requiring the heating of machinery and metal plates before machining.

Generally, it greatly reduces the waste of energy, economic and temporal. This is why many companies use it for sheet metal stamping in Turin and throughout Italy.

Conclusion on metal stamping

It's used for a very long time. Since it comes from the forging of metals - a process that develops together with humanity. without which it is impossible to imagine the creation of tools, construction tools and weapons.

Modern methods of manufacturing parts require not only high precision, but also material savings. While cutting metal, a very large part of it goes into chips maximum rationality. It consumes material, giving it a shape that practically does not need further processing.

Although the presses used for 금속 스탬핑의 are constantly evolving, increasing power and productivity. Their technical characteristics sometimes do not allow the creation of parts of very large sizes.

In this case, alternative methods come to the rescue. Such methods use hydraulic, explosive and electromagnetic forces.

The introduction of these methods into production allows you:

- to reduce the consumption of materials

- increase the accuracy and

- reliability of products and

- speed up the production processes.