Aluminium Extrusion manufacturer: A Guide to Extrusion

2020-08-25Aluminum Extrusion manufacturer: A Step by Step Extrusion Process

In recent times, there has been an increased demand for Aluminium Extrusion in product manufacturing and design. This led to an increase in the demand for a professional and reliable Aluminium Extrusion manufacturer. Technavia presented a report showing that there would be an annual growth rate of almost 4%.

In case, you are unaware of this manufacturing process, you are in the right place. In the course of this article, we will talk about Aluminium Extrusion in detail. So, without any further delay, let us get started!

Un guide sur l'extrusion d'aluminium

Qu'est-ce que l'extrusion d'aluminium?

C'est un processus qui force un matériau en alliage d'aluminium à travers une matrice tout en utilisant un profil en coupe transversale spécifique. Le fabricant utilise un bélier puissant pour faire passer l'aluminium à travers la matrice. En raison de la pression intense, l'aluminium sort de l'ouverture de la matrice.

Lorsque l'aluminium sort de l'avant de la matrice, il a la même forme que celle de la matrice. Une table de sortie sort alors l'aluminium. L'extrusion d'aluminium est facile à comprendre le processus, en particulier au niveau fondamental.

Vous pouvez lier la force appliquée pour pousser l'aluminium via l'avant de la matrice à celle de presser un tube pour faire sortir l'ingrédient. La substance présente à l'intérieur du tube prendrait la même forme que l'ouverture du tube après avoir appliqué une pression dessus.

So, it means that aluminum shape would depend upon the opening of the die. For round shape, you would require round opening, for square, square opening, and so on.

Shapes to be Extruded

You categorize the extruded shapes in three different categories.

1. Solid

Solid shapes do not have enclosed openings or voids. Angle, beam, or the rod are common examples that fall under this particular category.

2. Hollow

Hallow usually comes with one or more voids. For instance, a rectangular tube or a square tube.

3. Semi-hallow

These shapes generally have a void that is partially enclosed. For example, the “C” channel having a narrow gap.

Extrusion is popular among numerous industries including the energy, aerospace, electronics, automotive, architecture, and several other industries. You can achieve even extremely complex shapes by using multiple extrusion processes.

The Aluminium Extrusion Process

Below, we have explained the Aluminium Extrusion process in ten steps.

Step 1: Preparing and Moving the Extrusion Die

For starters, an Aluminium Extrusion manufacturer would use H13 steel for the machining a round-shape die. Of course, some manufacturers would already have the desired shape. In that case, they would simply pull it out from their warehouse.

The die needs to be preheated between 450 to 500 degrees Celsius. This would not only help maximize the lifespan of the die but at the same it, it would make sure that the metal flows evenly. Once you preheat the die, you can load it into the extrusion press.

Step 2: Heating Aluminum Billet Before Extrusion

The next step is heating the aluminum billet. It is basically a cylindrical solid block of aluminum alloy. Manufacturers extract the billet form a longer log of aluminum alloy material. You should have to preheat this in an oven. The temperature needs to be between 400 to 500 degrees Celsius.

Heating the billet would not melt it completely. However, it would make it malleable enough to yield to the extrusion process.

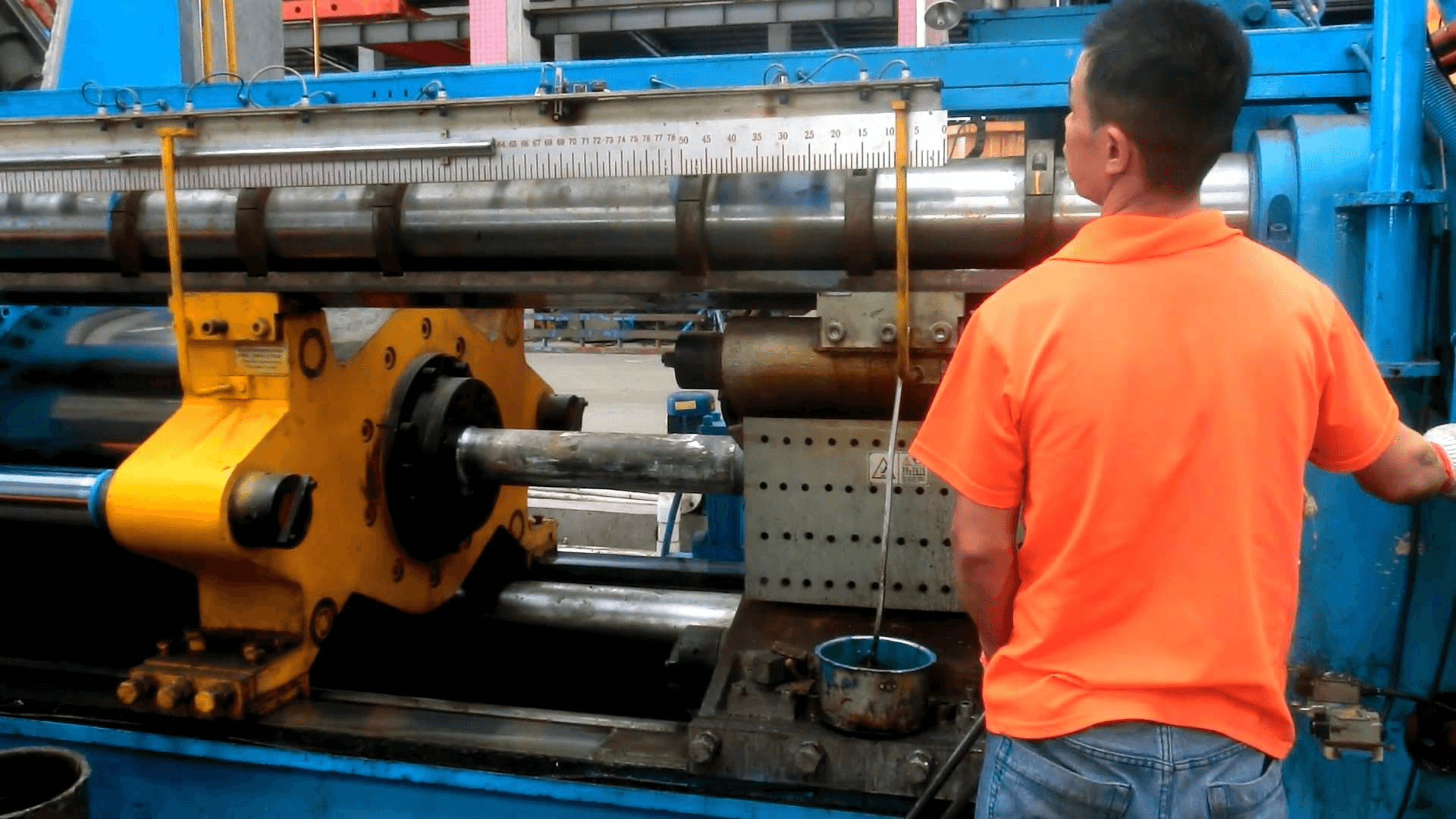

Step 3: Transferring Extrusion to the Billet Press

Once you heat the billet as required, it would mechanically be transferred to the extrusion press. However, applying a release agent or a lubricant onto the billet is important. This step needs to take place before the loading of the billet into the press.

Also, it is important to apply the same release agent to the extrusion ram. Doing so would ensure that the ram and the billet do not stick together.

Step 4: Pushing the Billet in the Container

After transferring the billet to the extrusion press, it is time for the apply the pressure. The ram would apply around 15,000 tons of pressure to the malleable billet. The application of the pressure forces the billet into the extrusion press’ container.

The material than would expand and gradually fill the container walls.

Step 5: Extruded Material Coming Out of the Die

Even after the material fills the container, the ram is still applying pressure. It means that now the material is pushed against the extrusion die. Due to continuous pressure, the aluminum material would go through the die’s opening.

When it comes out from the opening of the die, it is in the exact shape as that of the die opening. This means, that you have achieved your desired shape so far.

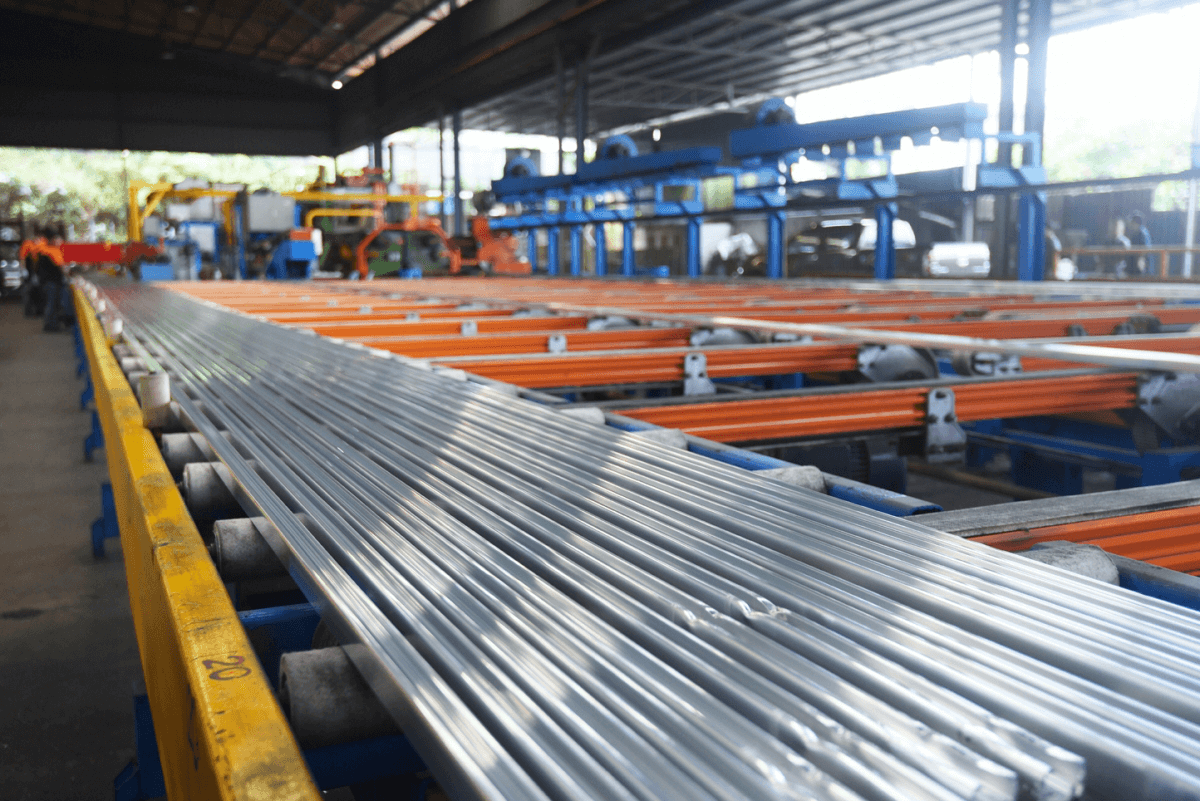

Step 6: Quenching and Runout Table

When the extrusion comes out from the die’s front, a puller holds onto it. This puller is then responsible for guiding it along with the run-out table. The speed of the table would match the speed at which the extrusion is coming out of the press.

Avec le mouvement de la table de sortie, le profil est trempé. Pour assurer sa robustesse, il doit être refroidi uniformément. Le fabricant d'extrusion d'aluminium utilise soit des ventilateurs situés au-dessus de la table, soit des bains-marie.

Étape 7: cisaillement par extrusion

Une fois que l'extrusion a atteint sa pleine longueur de table, il n'est pas temps de l'éloigner du processus d'extrusion. Dans ce but particulier, les fabricants utilisent une scie à chaud. La scie séparerait l'extrusion particulière du processus d'extrusion.

REMARQUE: La température est un aspect extrêmement important du processus d'extrusion. Vous devez le surveiller de près à chaque étape du processus d'extrusion.

Même si vous éteignez l'extrusion après sa sortie de la presse, il faut encore du temps pour refroidir complètement.

Étape 8: Refroidissement par extrusion à température ambiante

After the shearing takes place, it is time to transfer the extrusion from the run-out table to the cooling table. This process would take place mechanically. Now the manufacturer would wait for the profile to reach room temperature before shifting it to some other place.

After they cool down, it is important to let them stretch.

Step 9: Moving Extrusion to Stretcher

Sometimes, there is a certain twisting that occurs in the profile. As a professional Aluminium Extrusion manufacturer, you would have to work on it. In order to correct the problem, you move the table length extrusion on to a stretcher.

Every profile is gripped from both sides. It would mechanically be pulled until it reaches the desired specifications.

Step 10: Sawed According to Specifications

Now that the table length extrusions are fully cooled and they are straight as well, it is time to transfer them to the saw table.

Here, these extrusions are sawed according to the length. In general, the length ranges from eight to twenty-one feet.

NOTE: The properties of extrusion at this particular stage are similar to that of the T4 temper. After sawing, it is possible to age the extrusion to T5 or T6. In order to do so, you would have to move them to an aging oven.

The Final Touches

After the completion of extrusion, it is possible to enhance the properties of the profiles by giving them heat treatments. To enhance the finished look of the extrusions, Aluminium Extrusion manufacturer uses different finish types.

However, these finishes need to be done the heat treatments. To bring the extrusion to their final dimensions, they need to go through different fabrication operations.

Improving Mechanical Properties

It is possible to enhance the tensile strength and stress taking ability of alloys in the 7000, 6000, and 2000 series. In order to get these enhancements, it is important to put the profiles into ovens. These heating treatments would bring the alloys to T5 or the T6 tempers.

Surface Enhancement

There are numerous finishing operations that aluminum profiles would undergo. Surface enhancements not only improve the overall appearance of the aluminum but at the same time, it also improves it corrosion properties.

Par exemple, lorsque vous anodisez l'aluminium, cela entraînerait l'apparition naturelle de la couche d'oxyde. Ainsi, entraînant l'épaississement du métal. De plus, le procédé améliorerait la résistance à la corrosion du profilé. De plus, le métal deviendrait plus résistant à l'usure.

De même, il en résulterait une surface poreuse, cela signifie que la surface accepterait des couleurs différentes. L'émissivité de surface serait également améliorée.

Il existe également d'autres procédés de finition disponibles. Certains d'entre eux sont énumérés ci-dessous:

- Sablage

- Revêtement en poudre

- La peinture

- Sublimation

Sommaire

L'extrusion d'aluminium est un processus que les fabricants utilisent pour créer des composants et des pièces ayant certains profils transversaux. Pour améliorer à la fois les propriétés et l'apparence de l'aluminium, le fabricant utilise différents procédés mécaniques et d'amélioration de surface.

Le Le fabricant d'extrusion d'aluminium also uses certain fabrication process to acquire the final dimensions of the product. After all, their objective is to achieve high-quality aluminum parts.

In case, you are looking for an Aluminium Extrusion supplier or manufacturer, you can reach out to us. We will provide you with all that you are looking for.