Automobile

21/03/2020Qu'est-ce que CNC Automotive?

L'industrie des pièces automobiles CNC est la base et une partie importante du développement de l'industrie automobile. Le véhicule compte environ 30 000 pièces. Ils peuvent être divisés en pièces de système de moteur automobile, pièces de système de carrosserie, pièces de système de châssis, équipements électriques et électroniques et pièces générales selon leurs fonctions. Selon la classification des matériaux, il peut être divisé en parties métalliques et en parties non métalliques. Parmi eux, les pièces métalliques représentent environ 60% -70%, et les pièces non métalliques environ 30% -40%.

CNC automotive molds refer to molds used in the automotive field. They are called "mothers of the automotive industry." More than 90% of parts in automobile production rely on mold forming.

Generally, a car requires more than 1,000 to 1,500 sets of stamping dies. It accounts for about 40% of the total car output value. There are about 800 sets of plastic molds, about 300 pairs of sheet metal molds and about 100 sets of die-casting molds. Automobile stamping dies are important technical equipment for automobile production. Their design and manufacturing time accounted for about two-thirds of the entire car development cycle. They became one of the main constraints. Automobile stamping dies have the characteristics of large size, complicated working surfaces, and high technical standards, and are technology-intensive products.

Applications automobiles CNC

L'emboutissage automatique 1 automobile se réfère principalement aux pièces de forme et de taille requises. Ces pièces sont obtenues en déformant ou en séparant le matériau métallique de la matrice d'estampage extrudée par une force externe. Largement utilisé dans les housses de voiture, les systèmes de carrosserie, les systèmes de siège, les systèmes d'instrumentation et les systèmes d'échappement. Les pièces métalliques de carrosserie sont presque toutes des pièces estampées, et les pièces d'estampage automobiles sont l'industrie en aval des moules automobiles CNC.

L'estampage sur la carrosserie de la voiture est grossièrement divisé en plaques de recouvrement, panneaux de poutre et panneaux estampés ordinaires. Le sceau qui peut clairement représenter les caractéristiques d'une voiture est un panneau de voiture. Par conséquent, un moule d'automobile plus spécifique peut être considéré comme un "moule d'estampage de feuille d'automobile". Tout comme un moule de voiture.

Large and medium-sized automobile cover molds are an important part of body manufacturing technology and a key link in forming the independent development capability of automobiles. Automotive mold products include automobile cover molds, tire molds, plastic inner and outer molds, automotive lighting molds, automotive bumper molds and instrument panel molds.

Automotive Mold Market Development

With the increase in the development of new passenger vehicle models, the number of new models introduced has increased year by year. With the growth of the automotive market and the intensification of competition in the automotive market, the capacity of the automotive mold market will grow rapidly in the future. This is also the result of the rapid development of the automotive industry and the rapid development of new models.

Luo Baihui, secretary-general of the International Model Association, said that the market demand for automotive panel molds mainly depends on the number of new models to be launched each year, and the number of new models to be delivered mainly depends on the development of new models. Passenger cars (including cars with less than 9 seats, MPV, SUV, and minibus, etc.).

Car Cover Mold Level

According to the category of cover parts and the requirements of car manufacturers, car cover molds can be divided into three levels: low-end, mid-end and high-end. Among them, the supply of molds with low technical content is oversupply, and the profit margin of the market is narrow. The competition in the middle-end mold market is becoming increasingly fierce, and high-end molds with high technological content are far from meeting the market demand, and the development space is huge.

In the production of CNC automotive molds, Essai Mold has formed its own automotive mold system.

1. Automatic 3D design

From a design perspective, the manufacturing of high-end automotive stamping molds requires a parametric design of the molds. We need to combine software template technology to actively and effectively conduct secondary development to form a series of fixed, standardized design parameters, design templates, and achieve complete correlation and drive of parameters. By changing the parameters of the mold parts, quickly change the CAE results, mold process, and optimize the structure of the mold.

2. Simulating Stamping Process-Computer Aided Engineering (CAE)

The manufacture of automotive molds is inseparable from effective plate forming simulation software, and high-end automotive molds require full-process finite element simulation technology. An effective plate forming simulation software can improve the success rate of high-end automotive mold development and greatly shorten the manufacturing cycle of high-end automotive mold development. It can simulate and analyze the formability of automotive stamping parts, determine the difficulty of forming, and the key areas prone to stamping quality defects.

On the other hand, it can also calculate the roughness of automotive stamping parts. Secondly, it can also be used for selective and targeted simulation analysis of the structure and process plan of automotive molds. In addition, it can also provide quantitative analysis and judgment for the debugging of automobile molds. Data, determine feasible debugging solutions and provide specific technical parameters for the solutions. In short, the finite element simulation of the entire process can iteratively optimize the structure and process plan of automotive molds. In addition, we can use various simulations. It can be used to quantitatively analyze and verify the feasibility and reliability of automotive mold design before the on-site mold debugging, to optimize and improve the mold design in time.

3. Digital mold technology

Digital automobile mold technology mainly includes the following aspects: 1. Design for manufacturability (DFM). Consider and analyze manufacturability during the design process to ensure the process success. 2, mold surface design assistance technology, the development of intelligent profile design technology. 3. CAE assists in analyzing and simulating the stamping process, predicting and solving possible defects and forming problems. 4. Replace the traditional two-dimensional design with the three-dimensional mold structure design. 5. The mold manufacturing process uses CAPP, CAM and CAT technologies. 6 Under the guidance of digital technology, solve the problems in the process of test mold processing and stamping production.

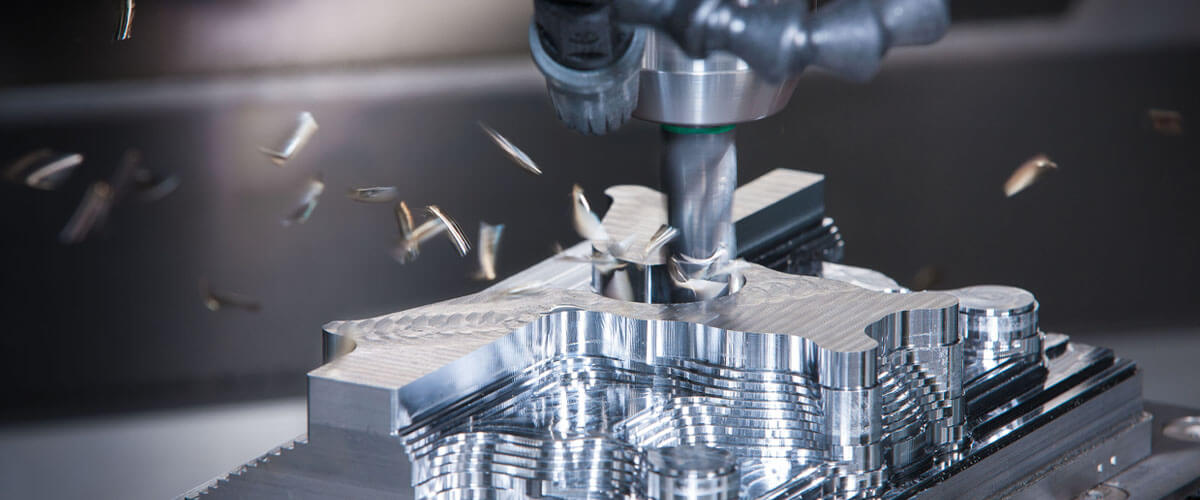

4. Mold processing automation

Equipé d'une machine CNC avec deux tables et un changeur automatique d'outils (ATC). Il s'agit à la fois de systèmes de commande optoélectroniques pour l'usinage automatique et de systèmes de mesure en ligne de pièces. L'usinage CNC est passé du simple usinage de contours à l'usinage complet des contours et des surfaces structurelles, de l'usinage à vitesse moyenne à l'usinage à basse vitesse en passant par l'usinage à grande vitesse.

5. Matériel de moule et technologie de traitement de surface

La qualité et les performances des matériaux de moulage sont des facteurs importants affectant la qualité, la durée de vie et le coût du moule. La fonte ductile a une bonne ténacité et porte la résistance, les performances de soudage, l'ouvrabilité et les performances de durcissement de surface. De plus, le coût est inférieur à celui de la fonte en alliage. Il a été largement utilisé dans la conception de moules de Have Mould.

6. Gestion de la science et de l’information

Scientific management makes Essai Mold develop in the direction of timely manufacturing and lean production. Make enterprise management more accurate and greatly improve production efficiency.

7. Multi-station progressive die

Multi-position progressive die can complete multiple stamping processes of parts, including stamping, bending, drawing and partial separation and continuous forming. The mold must have a high-precision guidance and positioning system, and be equipped with automatic feeding, automatic output, safety detection, and other devices. Although the mold structure is complex, it has many inserts, the mold manufacturing precision is high. And the manufacturing and assembly process is difficult. It is an important representative of technology-intensive automotive molds.

CNC Automotive Mold Industry

With the advent of electric vehicles, driverless technology, and new energy vehicles, energy-saving, environmental protection, and artificial intelligence, and automotive networking technologies have become increasingly important in the automotive industry. The rapid development of the new energy vehicle market has led to an increase in new models, which has brought huge market opportunities for the mold industry.

Because new energy vehicles emphasize energy reduction and efficient use of energy, lightweight materials have great potential in the market. For example, TESLA Model S, 95% aluminum alloy on the body structural parts. It is enough to see that the application of new materials in lightweight has become one of the core technical directions in the future. Especially the development of lightweight metal molding and polymer materials Molding and compound molding.

Automotive Electronics Mold

Dans le même temps, avec le développement rapide de la technologie de réseau automobile et l'amélioration continue de l'électrification et de l'intelligence, les moules électroniques automobiles ont également ouvert un espace de marché plus large. Les entreprises chinoises de moules pour l'électronique automobile déploient activement des services de réseau automobile, des composants clés et des produits à haute valeur ajoutée tels que les circuits intégrés, formant une synergie avec l'industrie électronique automobile. Dans le contexte du développement rapide des véhicules à énergie nouvelle et des voitures intelligentes. Ils peuvent utiliser des moules pour fabriquer des produits automobiles interactifs de conduite intelligente. Cela fournira un énorme espace de développement pour les composants fonctionnels haut de gamme!

Automatic 2 Since 2001, the global mold industry has been growing steadily, with an average growth rate of more than 5%. By 2012, the global mold industry market reached $ 94.5 billion. In the United States, Germany and Japan, and other developed countries. Their automotive-related mold demand accounts for more than 40% of the total mold demand. On this basis, the global automotive mold market has reached 37 billion U.S. dollars. According to the ratio of the output value of automotive stamping dies to 40% of the output value of automotive molds, the global automotive stamping mold market is approximately 15 billion U.S. dollars. At present, North America, Europe, and Japan, as the traditional automotive stamping die demand markets, still occupy an important position in global demand, and their market demand growth rates will remain relatively stable in the next few years.

Rapid Development of the Automotive Industry

The stable and rapid development of the automotive industry has created a good environment for the development of the automotive stamping mold industry. In the production process of automobiles, more than 90% of parts need to be formed by molds. Manufacturing a car requires more than 1,000 to 1,500 sets of stamping dies. The production of a country's cars to some extent reflects the overall condition of the country's auto molds. After the 2008 financial crisis, the auto output of traditional car producers. Such as the United States, Germany, and Japan showed a moderate recovery. However, demand in emerging markets such as China, India, and Brazil has grown rapidly. It is expected that from 2013 to 2020, the global light vehicle production growth rate will reach 3.6%. Among them, the growth rate of developing countries and automotive molds will reach 5.7%.