ラピッドプロトタイピングに関する究極の包括的なガイド| 中国

2020-06-07ラピッドプロトタイピング:知っておくべきことすべて

ラピッドプロトタイピングは比較的新しい用語です。 しかし、短期間で人気を博しました。 世界中の業界は、ラピッドプロトタイピングの使用に傾倒しています。 結局のところ、コストの削減、エラーのない生産など、多くのメリットがあります。

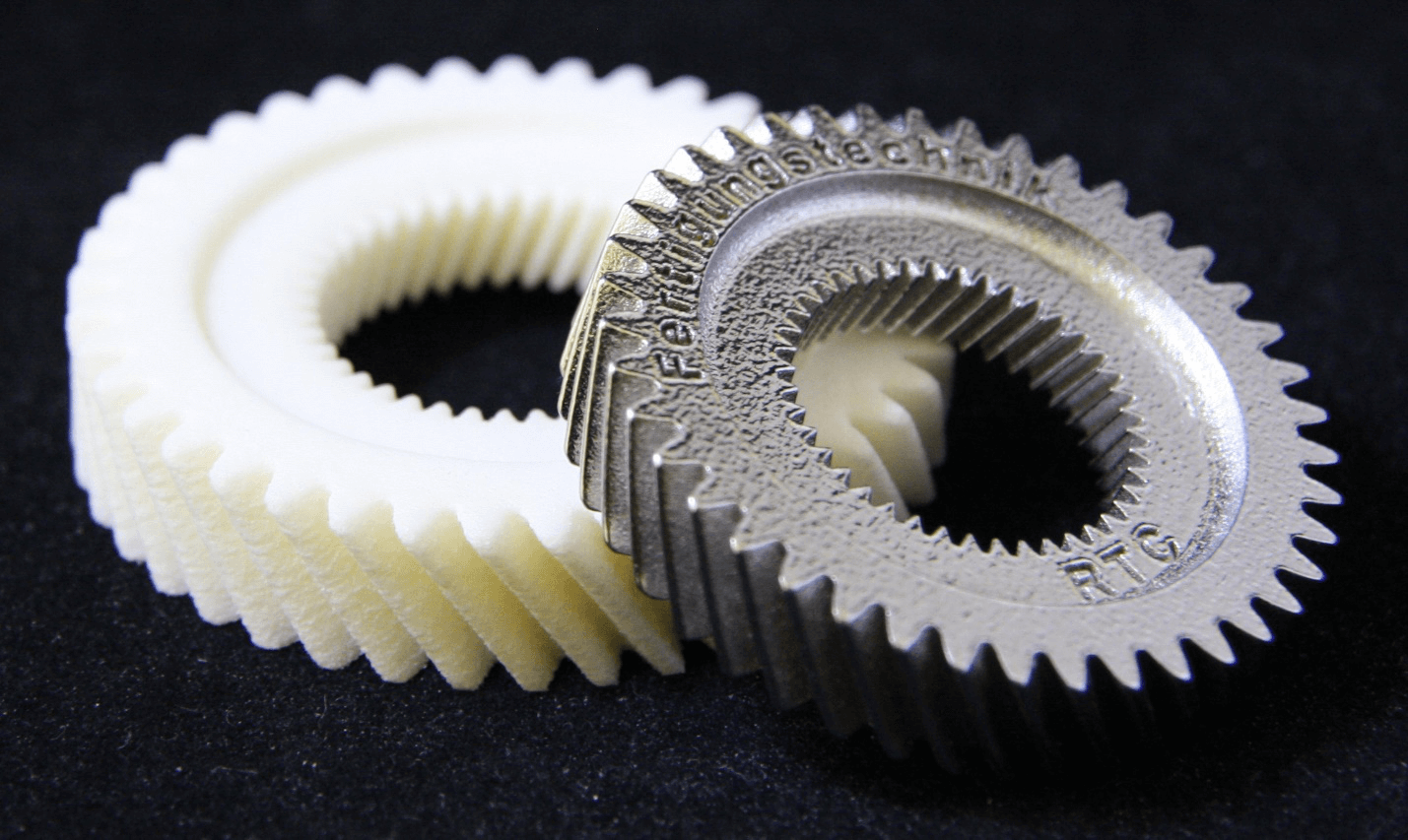

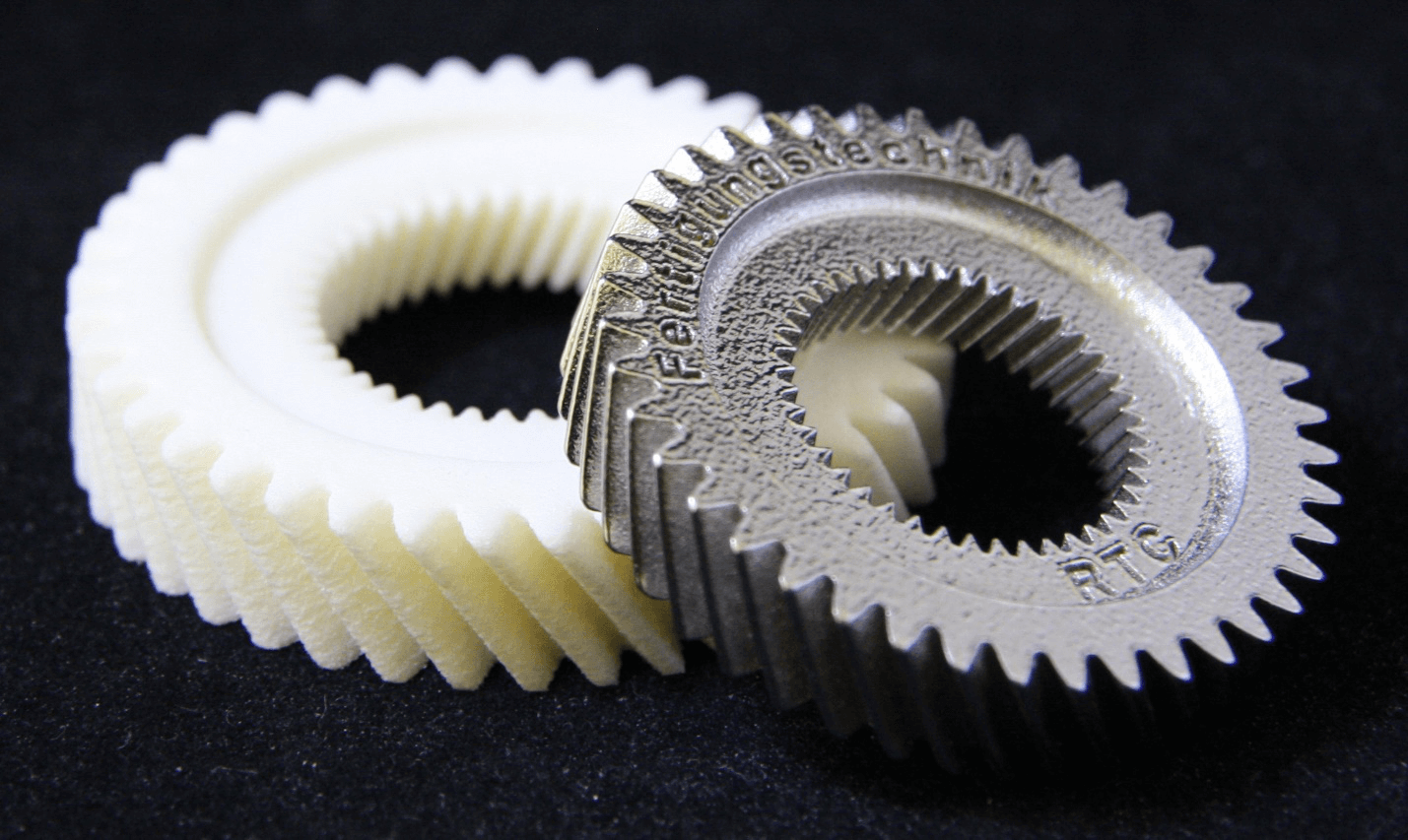

この方法には、多くの製造技術が組み込まれています。 これらの技術の中で最も一般的なのは積層造形です。 それにもかかわらず、製造業者がRPに使用する他の技術には、成形、押し出し、鋳造、および高速機械加工が含まれます。

したがって、このブログ投稿では、ラピッドプロトタイピング、そのタイプ、およびその利点について説明します。

ラピッドプロトタイピング入門

ソフトウェアの分野でプロトタイピングという用語を聞いたことがあるかもしれません。 彼らはそれを使用して、効果的かつ効率的な方法でソフトウェアを作成します。 プロトタイピングの同じルールが他の分野にも適用されます。

最も単純な形式では、ラピッドプロトタイピングをプロトタイプを効率的に作成することとして定義できます。 エンジニアはこれらのプロトタイプを使用して、製品設計の妥当性をテストします。 さらに、彼らは最終製品がどのように見え、機能するかを見ることができます。

より正式な定義は次のとおりです。プロトタイプは最終製品の暫定バージョンです。 これにより、設計の評価、動作の分析、および技術のテストが可能になります。 これにより、実際のシステムで機能する仕様の製品が得られます。

製品の設計におけるプロトタイプの重要性を否定することはできません。 さらに、製品の開発サイクル全体で重要な役割を果たします。 ラピッドプロトタイピングの良いところは、製品開発サイクルのどの段階でも使用できることです。

また、製品の特定のコンポーネントまたはサブコンポーネントに使用できます。 生産の面での多様性はRPを優れた選択にします。 さらに、プロトタイプには好きなだけ変更を加えることができます。

The endless iterations are not expensive especially when you compare them with the rework you might have to do in case of design error with the entire product batch.

Rapid-Prototyping: Different Techniques

Below, we have listed different types of Rapid-prototyping.

Vat Photopolymerization or Stereolithography

Vat photopolymerization is an inexpensive, yet efficient technique. Being the first fruitful marketable 3D printing technique, it became very popular in a short time. The technique uses a photosensitive liquid to make the prototype. The ultra-violet light monitored by a computer solidifies this liquid layer by layer to achieve the respective results.

Selective Laser Sintering -- (SLS)

SLS is an effective technique for both plastic and metal prototyping. It uses a powder bed to create one layer of the prototype at one time. To sinter and heat the powder material, SLS uses a high-power laser. Although, it can manipulate two different materials, it lacks the robustness of the SLA.

The prototypes created using SLS are not steady. Furthermore, most products require secondary work to achieve the surface of a finished product.

Fused Deposition Modelling

Another inexpensive rapid-prototyping technique is fused deposition. You will find this technique part of many non-industrial 3D printers. The procedure requires a spool of thermoplastic filament. It melts the material inside the nozzle barrel of the printer.

Now, the computer deposition program lays down the melted material layer by layer in accordance with the requirements. Initially, the fused deposition modeling offered low-quality and weak products. However, technological advancement has improved the entire process.

It still is affordable, yet the quality of the prototype has improved tremendously.

Selective Laser Melting

If the prototype you require is complex and should be highly durable, the SLM prototyping technique is your best shot. Industries like automotive, medical, defense and aerospace frequently use SLM.

The procedure makes use of fine metal powder. It melts the powder layer by layer, thus gradually upbuilding up the prototype. Manufacturers also use this technique to build robust and strong components. For melting the power, it uses either an electron beam or high-powered lasers.

Cobalt Chrome alloys, aluminum, titanium, and stainless steel are the common Selective Laser Melting materials.

Sheet Lamination

Unlike the SLS and SLM, Laminated Object Manufacturing lack the rigidness. There is no need for specially controlled conditions. The less sophisticated technique uses several laminates. These series of laminates are always thin. It then uses laser beams to cut these laminate piles to produce the CAD design.

To build the part, each layer is fused on top of the preceding one. The process goes on until the desired shape is achieved.

Binder Jetting

バインダー噴射は、複数の部品を同時に印刷する機能を提供します。 それは大量生産を提供します。 ただし、プロトタイプの品質はそれほど高くありません。 この手法では、パウダーベッドを使用します。 粉末粒子を結合するために、ノズルを介して液体の液滴を噴霧します。

これらの液滴は非常に微細です。 このプロセスは、パーツのすべてのレイヤーに対して繰り返されます。 さらに、粉末の次の層から始める前に、ローラーを使用して層を圧縮することが重要です。

これを行うと、プロセス全体が固まります。 製品の堅牢性をさらに高めるために、オーブンで硬化させます。 この硬化は、結合剤を焼き払うのに役立ちます。 同時に、適切なコヒーレント部分での粉末溶融に役立ちます。

デジタルライトプロセッシング

Digital light processing uses the same mechanism as that of the SLA. However, it does not require an extremely sophisticated method for the cure of polymerization of resins. It uses an orthodox light source to cure the resins.

Even though it is cheaper and faster in comparison to the SLA, the technique does require a post building curing. In addition, there is a need for support structures.

Prototype in Product Design

It is possible to category prototypes. However, this greatly depends upon the accuracy that is required by the consumer. In formal words, you can categorize prototypes based on fidelity.

- Fidelity Types

- Low Fidelity Prototype

These types of prototypes do not look like the final product. They may vary to a certain degree. The difference depends upon what the product designer wants to achieve from the prototype.

Low Fidelity

The low fidelity products are extremely simple. It is possible to produce them in a short period. The basic idea is to test the broader concepts, for instance, cardboard mock-ups or paper sketches.

High Fidelity

The high-fidelity products are extremely similar to that of the final product. They not only look like the final product but also offer most of its functionality.

Why Rapid Prototyping is Important?

For a company to stay afloat in the modern-day, fast-moving consumer market, it needs to be innovative. Not only this, but the company also needs up to come up with better, advance, and sophisticated products fast to ensure competitiveness.

Since technology innovation and faster product development plays a vital role in the company’s success, therefore, the rapid prototyping becomes an important part of the development cycle of the product.

With rapid prototyping, it is possible to achieve the following.

- Prototyping makes it possible to create newer products efficiently. It tends to speed up the entire product development cycle.

- It is possible for the engineers to determine whether their product idea will work or not well before stepping into the production phase. With RP, you can actually validate your product design idea.

- It also offers the final stage product verification against the business objectives and the technical requirement.

- With prototyping, the end-users, customers, clients can give feedback in real-time as they would have a tangible product to work with.

取り除く

Rapid Prototyping aids technology innovation in every possible way. It lets developers and engineers validate the product idea. In addition, it lets you find any fault in the product design, well before the production phase.

With rapid-prototyping, you can actually transform your idea into something tangible. You can present the idea to investors with more confidence and increase the chances of landing them.