Un ghid final și cuprinzător privind prototiparea rapidă | China

07.06.2020Prototipare rapidă: tot ce trebuie să știți

Prototiparea rapidă este un termen relativ nou. Cu toate acestea, a reușit să câștige popularitate pe o perioadă scurtă. Industriile din întreaga lume devin înclinate spre utilizarea prototipurilor rapide. La urma urmei, oferă o serie de avantaje, cum ar fi costuri reduse, producție fără erori etc.

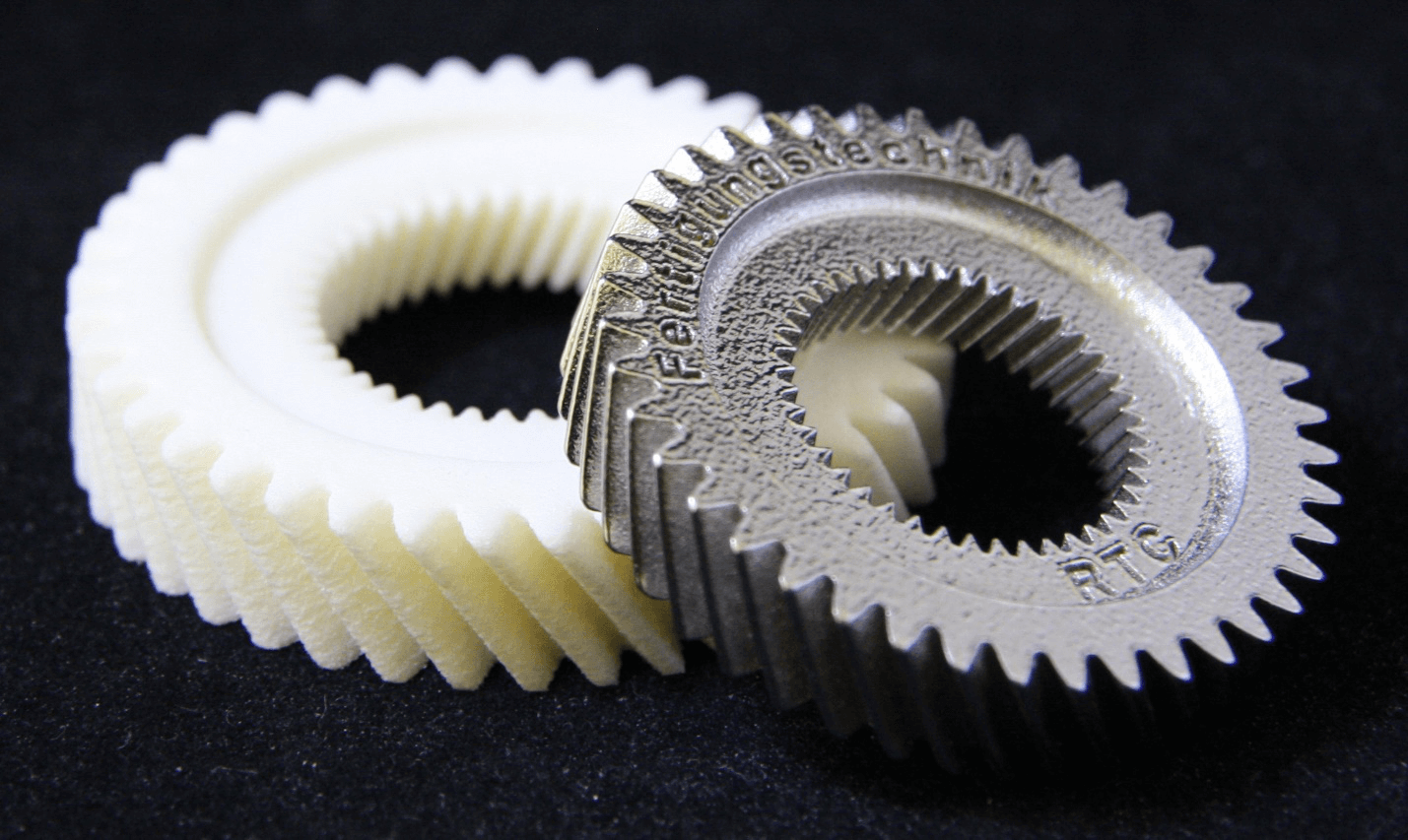

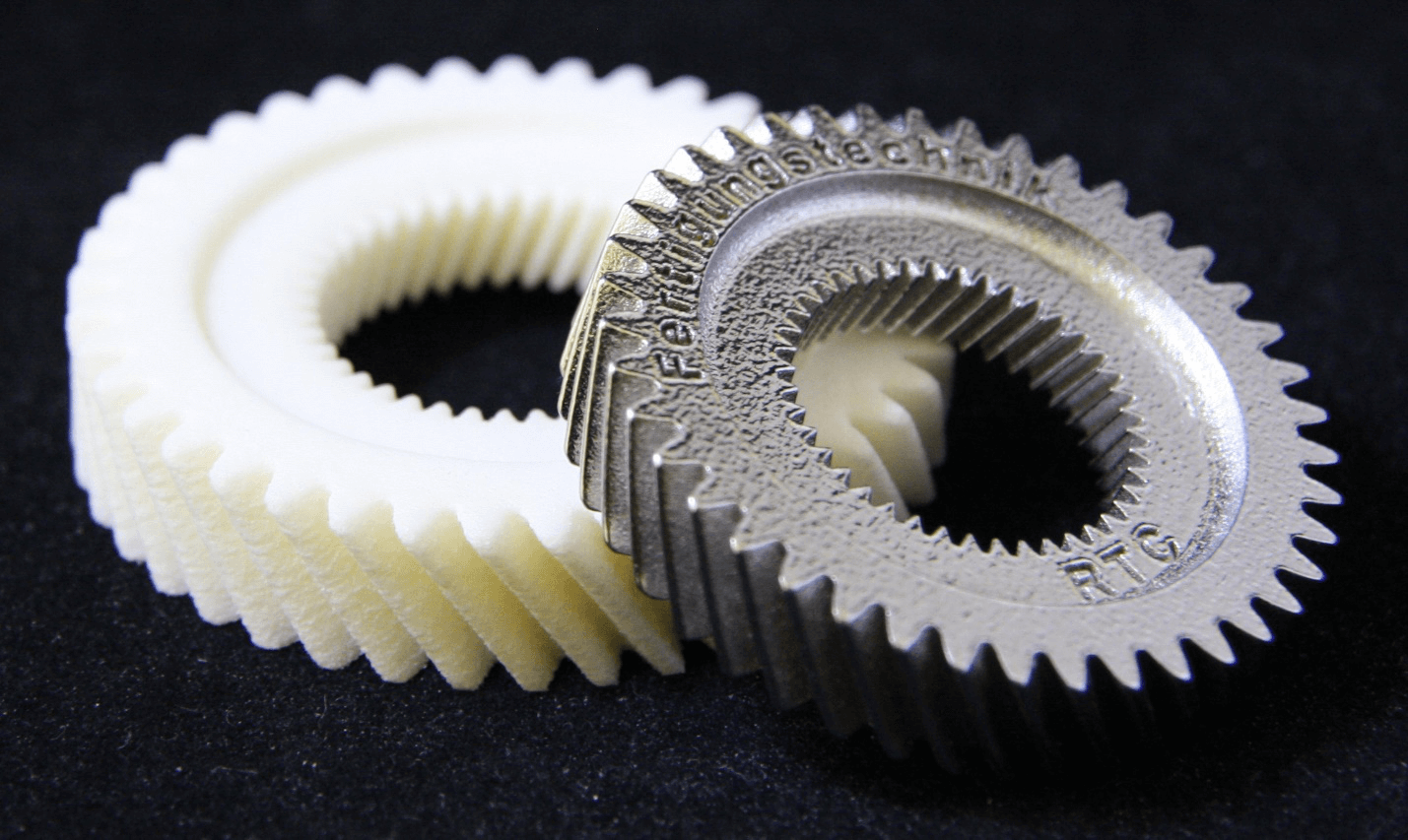

Metoda încorporează o serie de tehnologii de fabricație. Cea mai comună dintre aceste tehnologii este fabricarea aditivă. Cu toate acestea, există și alte tehnologii pe care producătorii le folosesc pentru RP: turnare, extrudare, turnare și prelucrare de mare viteză.

Deci, în această postare de blog, vom vorbi despre prototiparea rapidă, tipurile sale și avantajele sale.

Introducere în prototiparea rapidă

Este posibil să fi auzit termenul de prototipare în domeniul software. Ei îl folosesc pentru a crea software într-un mod eficient și eficient. Aceeași regulă a prototipurilor se aplică și în alte domenii.

În cea mai simplă formă, putem defini prototiparea rapidă ca fiind crearea eficientă a prototipurilor. Inginerii folosesc aceste prototipuri pentru a testa validitatea designului produsului lor. Mai mult, ei pot vedea cum ar arăta și cum ar funcționa produsul final.

A more formal definition is: Prototype is a preliminary version of an end-product. It makes it possible to evaluate the design, analyze its working, and test its technology. This results in a product that has the specification that would work in the real-world system.

There is no denying the importance of prototypes in designing the product. In addition, it plays a vital role in the overall development cycle of the product. The good thing about rapid-prototyping is that you can use it at any stage of the product development cycle.

Moreover, you can use it for a certain component or a sub-component of the product. The versatility in terms of production makes RP an excellent choice. What more is that you can make as many changes to the prototype as you like.

Iterațiile nesfârșite nu sunt scumpe mai ales atunci când le comparați cu prelucrarea pe care ar trebui să o faceți în caz de eroare de proiectare cu întregul lot de produse.

Prototipare rapidă: tehnici diferite

Mai jos, am enumerat diferite tipuri de prototipare rapidă.

Fotopolimerizare cu TVA sau stereolitografie

Fotopolimerizarea cuvei este o tehnică ieftină, dar eficientă. Fiind prima tehnică fructuoasă de imprimare 3D comercializabilă, a devenit foarte populară în scurt timp. Tehnica folosește un lichid fotosensibil pentru a face prototipul. Lumina ultravioletă monitorizată de un computer solidifică acest lichid strat cu strat pentru a obține rezultatele respective.

Sinterizare laser selectivă - (SLS)

SLS is an effective technique for both plastic and metal prototyping. It uses a powder bed to create one layer of the prototype at one time. To sinter and heat the powder material, SLS uses a high-power laser. Although, it can manipulate two different materials, it lacks the robustness of the SLA.

The prototypes created using SLS are not steady. Furthermore, most products require secondary work to achieve the surface of a finished product.

Fused Deposition Modelling

Another inexpensive rapid-prototyping technique is fused deposition. You will find this technique part of many non-industrial 3D printers. The procedure requires a spool of thermoplastic filament. It melts the material inside the nozzle barrel of the printer.

Now, the computer deposition program lays down the melted material layer by layer in accordance with the requirements. Initially, the fused deposition modeling offered low-quality and weak products. However, technological advancement has improved the entire process.

It still is affordable, yet the quality of the prototype has improved tremendously.

Selective Laser Melting

If the prototype you require is complex and should be highly durable, the SLM prototyping technique is your best shot. Industries like automotive, medical, defense and aerospace frequently use SLM.

The procedure makes use of fine metal powder. It melts the powder layer by layer, thus gradually upbuilding up the prototype. Manufacturers also use this technique to build robust and strong components. For melting the power, it uses either an electron beam or high-powered lasers.

Cobalt Chrome alloys, aluminum, titanium, and stainless steel are the common Selective Laser Melting materials.

Sheet Lamination

Unlike the SLS and SLM, Laminated Object Manufacturing lack the rigidness. There is no need for specially controlled conditions. The less sophisticated technique uses several laminates. These series of laminates are always thin. It then uses laser beams to cut these laminate piles to produce the CAD design.

To build the part, each layer is fused on top of the preceding one. The process goes on until the desired shape is achieved.

Binder Jetting

Binder jetting offers the facility of printing several parts at the same time. It does offer mass production; however, the quality of the prototype is not very strong. The technique uses a powder bed. To bind the powder particles together, it sprays droplets of the liquid via nozzles.

These liquid droplets are micro-fine. This process is repeated for every layer of the part. Moreover, it is important to compact a layer using a roller, before starting with the next layer of the powder.

Doing this solidifies the entire process. To further enhance the robustness of the product, it is cured in an oven. This curing helps to burn off the binding agent. At the same time, it helps in powder fusing in just the right coherent parts.

Prelucrarea digitală a luminii

Prelucrarea digitală a luminii utilizează același mecanism ca cel al SLA. Cu toate acestea, nu necesită o metodă extrem de sofisticată pentru vindecarea polimerizării rășinilor. Folosește o sursă de lumină ortodoxă pentru a vindeca rășinile.

Chiar dacă este mai ieftină și mai rapidă în comparație cu SLA, tehnica necesită o întărire post-construire. În plus, este nevoie de structuri de sprijin.

Prototip în proiectarea produselor

Este posibilă clasificarea prototipurilor . Cu toate acestea, acest lucru depinde în mare măsură de acuratețea cerută de consumator. În cuvinte formale, puteți clasifica prototipurile pe baza fidelității.

- Tipuri de fidelitate

- Prototip Low Fidelity

These types of prototypes do not look like the final product. They may vary to a certain degree. The difference depends upon what the product designer wants to achieve from the prototype.

Low Fidelity

The low fidelity products are extremely simple. It is possible to produce them in a short period. The basic idea is to test the broader concepts, for instance, cardboard mock-ups or paper sketches.

High Fidelity

The high-fidelity products are extremely similar to that of the final product. They not only look like the final product but also offer most of its functionality.

Why Rapid Prototyping is Important?

For a company to stay afloat in the modern-day, fast-moving consumer market, it needs to be innovative. Not only this, but the company also needs up to come up with better, advance, and sophisticated products fast to ensure competitiveness.

Since technology innovation and faster product development plays a vital role in the company’s success, therefore, the rapid prototyping becomes an important part of the development cycle of the product.

With rapid prototyping, it is possible to achieve the following.

- Prototyping makes it possible to create newer products efficiently. It tends to speed up the entire product development cycle.

- It is possible for the engineers to determine whether their product idea will work or not well before stepping into the production phase. With RP, you can actually validate your product design idea.

- It also offers the final stage product verification against the business objectives and the technical requirement.

- With prototyping, the end-users, customers, clients can give feedback in real-time as they would have a tangible product to work with.

Take Away

Rapid Prototyping aids technology innovation in every possible way. It lets developers and engineers validate the product idea. In addition, it lets you find any fault in the product design, well before the production phase.

With rapid-prototyping, you can actually transform your idea into something tangible. You can present the idea to investors with more confidence and increase the chances of landing them.