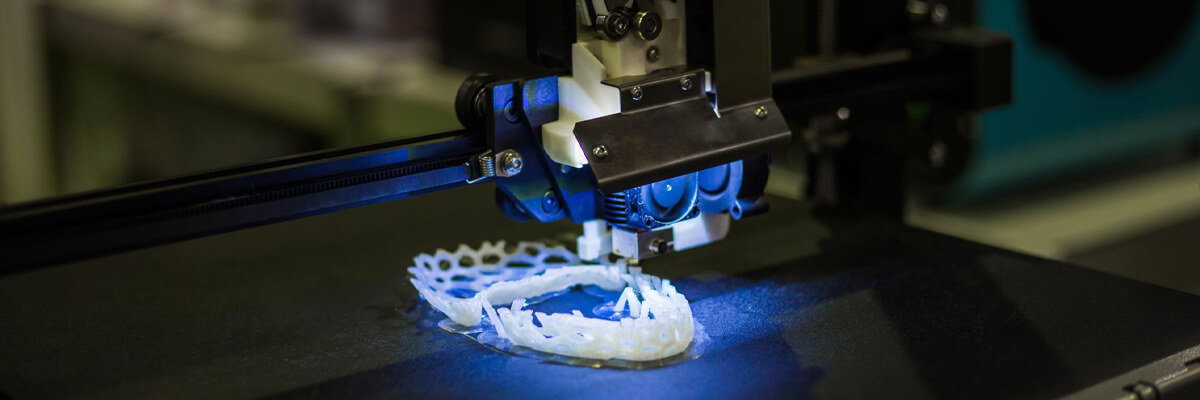

3D rapid prototype is a quick, easy, cost effective way to turn great ideas into successful products. Do you need concept modeling to put your newest ideas to the test? What about functional prototyping to gauge performance before committing to costly production tooling? Rapid prototyping solutions from Essai will give you the flexibility to create, test and refine in ways you never thought possible so you can go to market faster than ever before.

Advantages of 3D Rapid Prototype

Rapid prototyping provides engineer, design and development teams with a distinct advantage such as:

- The ability to explore and realize concepts more quickly. This efficiency in time and cost allows teams to move beyond the mere visualization of a product, making it easier to grasp the properties and design of a product.

- Apply repeated designs and incorporate changes that allow for the evaluation and testing of the product. This iterative process provides a roadmap to developing and refining the final product.

- Being able to communicate concepts concisely and effectively. Rapid prototyping takes ideas, images, and concepts from flat and 2 dimensional visuals to hands-on products that clients, colleagues, and collaborators can then see in action.

- The ability to thoroughly test and refine a concept. Being able to minimize design flaws with a small volume rapid prototype run helps eliminate costly design flaws that might not be evident during an early assessment.

- Save time and money since setup and tooling aren’t necessary. Because the same equipment can be used to produce prototypes with different properties and materials, the costs and time outlay are kept to a minimum.

3D Rapid Prototype Applications

Rapid prototyping is applicable to many materials and technologies, making it a versatile technique that can be employed for numerous applications. A few ideas include the following:

- Concept models provide designers with the opportunity to validate both their ideas and the assumptions that lie behind them. A physical concept model is an ideal way to explore a concept, demonstrate its validity to stakeholders and/or create communication surrounding it.

- Functional prototypes enable designers and developers to grasp the details that provide an accurate representation of the finished product by allowing them to verify its validity before it moves onto the next stage. The fit, design, manufacturability, and function of the product can be tested prior to moving it into full production mode — an infinitely more costly process.

- Proving that a working prototype is also going to be economically feasible to manufacture is another application of rapid prototyping. Having a fantastic prototype that achieves a satisfactory balance of functionality and aesthetics while also being cost-effective is possible with rapid prototyping.

| CNC 가공 여부 | CNC 가공 |

| Material Capabilities | 알루미늄, 황동, 청동, 구리, 경화 금속, 귀금속, 스테인리스 강, 강철 합금 |

| Micro Machining or Not | Micro Machining |

| 재료 | Aluminum alloy 6063, 6082, 6061 |

| 색깔 | Color Availale |

| 크기 | Customized Size |

| Finish | Anodized / polish / brush |

| 신청 | Industrial / Auto |

| 서비스 | 맞춤형 OEM |

| Usage | Field Parts |

| Processing Way | CNC milling, CNC lathe, Drilling, etc |

| 증명서 | ISO19001 |

| 꾸러미 | 비닐 봉투 및 카톤; 고객의 요구 사항 |

Essai 의존의 장점

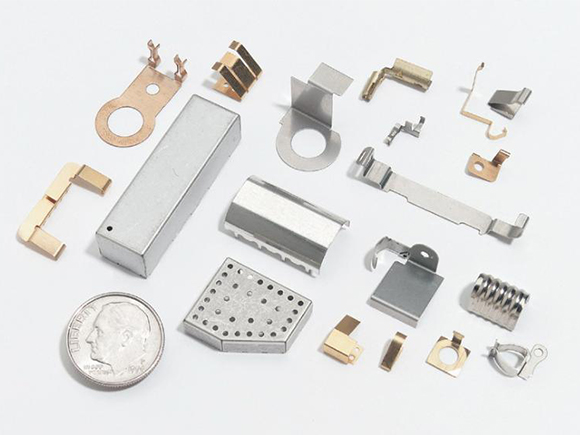

1. 알루미늄 제품의 다이캐스팅은 경쟁력있는 가격으로 제공됩니다.

2. 우리는 지금 14 년 이상 동안 작은 금속 합금 성분을 전문화합니다.

3. 우리는 알루미늄 주조 합금 및 기타 제품을 만들기 위해 최고의 전문가와 현대 기술을 사용합니다.

4. 우리는 하드웨어, 컴퓨팅, 의료 및 자동차와 같은 다양한 산업에서 서비스를 제공합니다.

5. 우리의 제품은 당신에게 좋은 명망을주기 위하여 보장되고 우리는 질의 높은 기준을 고착합니다.

6. 우리는 제품의 광범위한 테스트를 수행합니다.

7. 조직에서 하나 이상의 솔루션이 가능합니다.

8. 귀하의 아이디어와 디자인은 전문가가 새로운 정의를 내릴 것입니다.

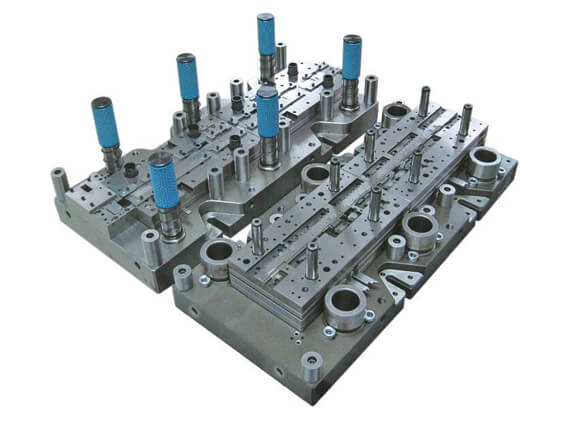

- Rapid Injection Molding – A low-cost rapid mold can be used for a small number of parts for a low cost.

- Digital Light Processing – It has good tolerance to the design and has a good surface finish.

- CNC Machining – An ideal choice for plastic without costly tooling. It holds tighter tolerances and has a better surface.

- Selective Laser Sintering (SLS) – SLS is for plastic prototypes with intricate internal designs.

- Laminated Object Manufacturing – A good option using thin laminates laid layer by layer for plastic. The designs should not be complex, but LOM is a low cost compared to others.

- Selective Laser Melting (SLM) – SLM is the preferred option for parts requiring high strength, high durability, and complex intricate design.

- Fused Deposition Modeling (FDM) – FDM includes a low cost, ease of us, and using multiple plastic types and colors in one prototype.

- Stereolithography (SLA) – good for low volume production parts with a quality finish and increased strength.

- Binder Jetting – A big advantage in making multiple parts at one time at a lower cost.

유사한 경우

다양한 산업의 기업에 기술 하드웨어 지원을 제공합니다.

충분히 모르십니까?

저희에게 연락을 환영하고 지금 귀하의 사업을 시작하십시오!

사무실 : No.72-6, Huanguan South Road, Longhua New District Shenzhen, 518110 중국

공장 : No.333 Xiangmang West Road Qingxi Town, Dongguang, China