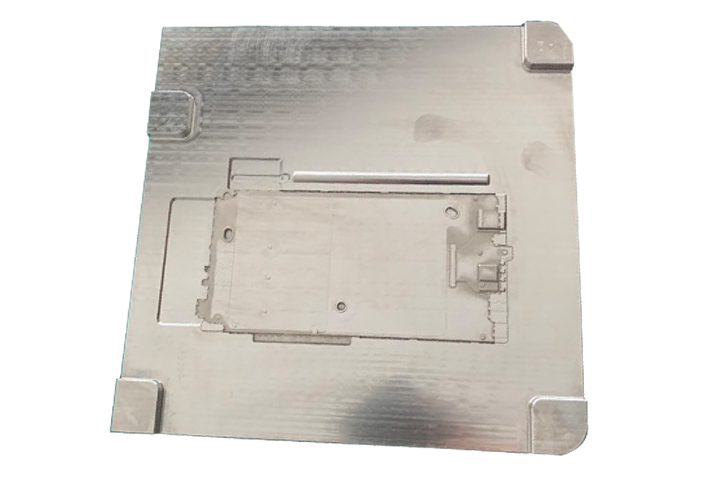

알루미늄 제품의 CNC 가공 프로그래밍 팁

2020-03-28알루미늄 제품의 CNC 가공 프로그래밍 팁

프로그래밍은 알루미늄 제품의 CNC 가공에서 없어서는 안될 단계이지만 많은 초보자는 CNC 가공 프로그래밍을 이해하지 못합니다. 가공을 프로그래밍하고 작동 할 때 CNC 머시닝 센터에서 충돌을 피하는 것이 필요합니다. 다음으로 CNC 가공 프로그래밍에 대한 몇 가지 팁을 공유하겠습니다.

1.Using computer simulation software

With the development of electronic information technology and the continuous development of classroom teaching of CNC lathe machining, there are more and more software for CNC lathe machining simulation system, and its role is increasingly perfect. Therefore, it can be used to basically check the data and observe the fitness movement of the cutter to determine whether there is a collision.

2.Using the built-in simulation of CNC machining center to display the role of information

Generally, the excellent CNC machining centers often have the function of graphic display information. After entering the program flow, you can enable the graphical simulation to display the effect of the information, and observe the trajectory of the tool in detail to facilitate checking whether the tool will collide with the workpiece or fixture.

3. Utilize the empty operation function of CNC machining center

The accuracy of the trajectory of the infeed can be checked by using the dry operation function of the CNC machining center. After the program flow is entered into the CNC machining center, the tool or workpiece can be mounted, and then the empty operation button is pressed. At this time, the spindle bearing does not rotate, and the operating table starts automatically in strict accordance with the movement trajectory. Collision with the workpiece or fixture. However, under such circumstances, it must be ensured that the tool cannot be installed when a workpiece is provided; when the tool is installed, the workpiece cannot be installed, otherwise collision will occur.

4.Using the locking effect of CNC machining center

General CNC machining centers have a locking function (full lock or double shaft lock). When the program flow is entered, the Z axis is locked, and it can be distinguished whether a collision will occur based on the plane coordinates of the Z axis. The use of this effect should be bypassed by tool change or other operations, otherwise the program flow cannot be based.

5. 평면 좌표 및 커터 보정 설정이 적절해야합니다

. CNC 머시닝 센터를 시작할 때 CNC 머시닝 센터 기계 좌표계를 설정해야합니다. CNC 머시닝 센터의 평면 좌표는 특히 Z 축 방향에서 프로그래밍과 일치해야합니다. 오류가 발생하면 선삭 공구와 공작물 간의 충돌 가능성이 매우 큽니다. 또한 공구 길이 보정을 적절하게 설정해야합니다. 그렇지 않으면 빈 생산 처리가 아니거나 충돌이있는 경우.

6. 프로그래밍 방법 개선

프로그래밍은 CNC 선반 가공에서 특히 중요한 단계입니다. 향상된 프로그래밍 방법은 매우 큰 수준에서 불필요한 충돌을 방지 할 수 있습니다.

All in all, grasping the programming method of cnc machining center can improve the efficiency and quality of production and processing as soon as possible, and prevent unnecessary errors in production and processing. This requires the beginners of CNC machining centers to continue to learn from the actual experience and continuously improve, so as to further strengthen the programming and production capabilities. If as a beginner this level is not very mastery, we should learn more and train more professional and technical personnel with rich experience.