자동 스탬핑 부품 비용은 얼마입니까? (툴링 제조를위한 장비 선택)

2020-11-23How much 자동 스탬핑 부품 Cost? (Equipment selection for tooling Manufacturing)

자동 스탬핑 부품 are common in engineering, shipbuilding, aircraft construction. Only earlier we used to carry it manually. In addition, the method gained wide popularity. Because it was possible to make everything - from a small, insignificant part, to an airplane wing.

Today's technologies and equipment allow automatic metal stamping. This process has a number of advantages, which we will discuss below.

What is Auto Stamping Parts?

There are two methods of metal processing:

- cold and

- hot

Generally, cold forging is common in producing:

- machine bodies

- aircraft parts

- and other single or multi-batch parts.

The advantages of cold stamping include the cost-effectiveness of consumables. Moreover, it increases the ability to manufacture parts that will absolutely match each other, and high production efficiency.

자동 스탬핑 부품 is a technological process that we use to produce metal sheets up to 4 mm in volume. Moreover, during operation, the material is subjected to high heating. And then special machines carry the process.

How does Auto Stamping work?

고객의 도면에 따라 자동 금속 스탬핑을 사용하면 단일 버전 및 다중 배치에서 원래 구성 및 모양의 제품을 만들 수 있습니다. 자동 스탬핑 덕분에 부품이 정확히 동일합니다. 마찬가지로 오류는 최대 0.05mm 일 수 있습니다.

금속 스탬핑의 기술 프로세스 :

- 두 개의 판금 조각이 직선 또는 곡선으로 작동합니다.

- 노칭 . 결과적으로 노치 및 절단은 시트의 전체 무결성을 방해하지 않고 금속에서 작동합니다.

- 동시에 프로세스는 시트의 가장자리와 함께 작동하도록 설계되었습니다. 또한 불필요한 부분을 벗겨서 낭비합니다.

- 펀칭. 자동 스탬핑 부품 프로세스. 따라서 패턴 또는 패턴이 나타납니다.

- Cutting down. A closed loop is made inside the metal blank and a whole fragment is removed along it. In this case, the entire part remains closed.

- It is a decorative element that allows you to correct irregularities in the metal sheet and smooth the ends.

- Cones appear on the metal surface, in other words, breaks, but without cutting off the metal layer.

How much Auto Stamping Parts Cost?

The most frequently asked and popular question: "How much does a stamped part cost?"

To calculate the cost of manufacturing, you need to add the following components:

- material cost + shipping cost / useful output (pcs),

- cost of design documentation + cost of a stamp + cost of commissioning / estimated life of a stamp,

- Cost of medium and minor repair of a stamp + cost of spare parts. Moreover, it also includes / number of parts produced from service to service,

- Moreover, Shift cost / production rate.

- Information for customers

- Generally, mass production of metal products requires technology, raw materials, equipment and tooling.

- a) Technology - we will develop,

- b) raw materials - we will purchase,

- c) equipment - in stock,

- d) equipment - we will design and order.

- We work using your tooling and can make our own.

Technology development of auto stamping

This is the very first stage of 자동 스탬핑 부품. Furthermore, here the cost of the part depends. At this stage, you need to clearly understand your monthly need. Based on many years of experience, we will develop the most optimal manufacturing technology for the parts you need according to the criteria "need - terms - price - quality".

At the moment, for cold stamping of parts, you can select the required steel grade: cold-rolled, hot-rolled, cold-worked, stainless, etc. Moreover, there is cretion of waste during the production of steel products. Unlike foundries, this waste cannot be recycled locally and must be disposed of. Therefore, we include the costs of disposal in the price of the products.

- Metal waste from production can range from 3 to 80%.

- Material selection - steel grade Material selection - steel grade

Equipment selection for Auto Stamping Parts

For the production of products based on the technology, equipment is selected taking into account:

- the steel grade

- the size of the workpiece

- the permissible force of the forging and

- Pressing equipment and the size of the finished product.

Production of documentation

For the manufacture of dies, design documentation is required - drawings. Similarly, the term for the development of design documentation is 3-4 weeks. The cost of a set of drawings for a stamp depends on the project.

Moreover, the development of design documentation is an important process. Therefore, we recommend checking cost of the forming equipment.

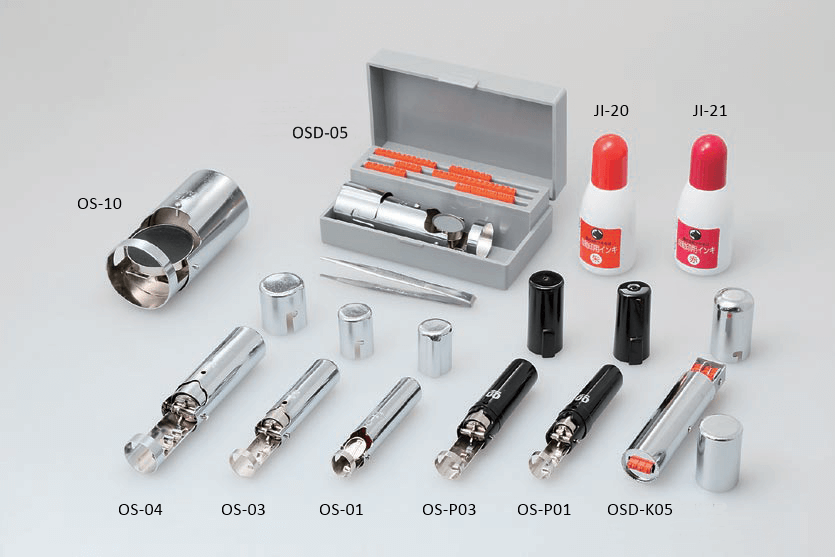

Tooling (stamp) manufacturing

For the manufacture of tooling (stamp), it is enough for us to receive a drawing or a sample of the part from you. Furthermore, you can allocate the cost of 자동 스탬핑 부품. For the manufacture of large batches of products on an ongoing basis, it is necessary to have at least two sets of dies. Subsequently, it is in order to ensure the required volumes of products. Moreover, it is to exclude downtime in the event of their breakdown.

How to even approximately understand the cost of Auto Stamping Parts?

Generally, the more complex the part, the larger the holes in it, the larger its size - the higher the cost of the stamp.

In addition, the term for making a stamp is from 1 month, the term for debugging a stamp is up to 2 weeks

Service stamps

스탬프는 높은 운영 부하를 겪고 정기적 인 유지 보수가 필요한 장비입니다.

- 검사

- 부품 교체

일반적으로 금형의 중소 수리는 작동 시간과 필요에 따라 수행됩니다. 자동 스탬핑 부품 생산 시설을 운영 사이트에 전달합니다. 마찬가지로 다음이 포함됩니다.

- 분해

- 결함 찾기

- 마모 부품 교체

- 절단면의 선명 화

- 감자 및 조립

Descartes 펀칭 스캐너 포지셔너의 장점

펀칭 효율성 향상 :

- 조달 비용 절감

- 또한 생산성이 향상됩니다 (최대 위치 결정 속도 50,000mm / 분).

재료 저장 :

- 하나의 금속 볼륨에서 5 배 더 많은 부품,

- 따라서 폐기물을 2.5 배 감소시키고,

- 비 유동성 블랭크에서 스탬핑 가능성.

최대 9 배의 임금 절감 :

- One person can serve 3 presses.

Reducing the price of stamps by 30%:

- Moreover, you can use 2-column and non-column dies,

- Stamps without guides, stepping knives and catchers.

Occupational Safety and Health:

- The presence of a person directly near the press is not required.

Brief Description of Auto Stamping Parts Scanner-Positioner Assemblies

- High strength frame

자동 스탬핑 부품 includes the high-strength, full-size frame. Similarly, it comes with high-tech welding. Moreover, it can withstand loads of up to 63 tons, ensuring stable and reliable operation.

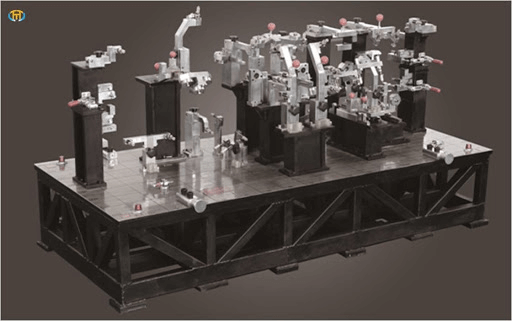

Stamp frame Descartes Stamp frame Descartes

- Technology of compensation of unevenness of the workpiece

Generally, the roller can freely follow the curvature of the sheet surface. To compensate for unevenness of the sheet during travel, the drive rollers have a vertical stroke.