Berapa Kos Bahagian Stamping Auto? (Pemilihan peralatan untuk pembuatan perkakas)

2020-11-23Berapa Bahagian Stamping Auto ? (Pemilihan peralatan untuk pembuatan perkakas)

Bahagian Stamping Auto adalah perkara biasa dalam bidang kejuruteraan, pembinaan kapal, pembinaan pesawat. Hanya sebelum ini kita biasa membawanya secara manual. Di samping itu, kaedah ini mendapat populariti yang luas. Kerana mungkin untuk membuat segalanya - dari bahagian kecil, tidak signifikan, hingga sayap kapal terbang.

Today's technologies and equipment allow automatic metal stamping. This process has a number of advantages, which we will discuss below.

What is Auto Stamping Parts?

There are two methods of metal processing:

- cold and

- hot

Generally, cold forging is common in producing:

- machine bodies

- aircraft parts

- and other single or multi-batch parts.

The advantages of cold stamping include the cost-effectiveness of consumables. Moreover, it increases the ability to manufacture parts that will absolutely match each other, and high production efficiency.

Bahagian Stamping Auto is a technological process that we use to produce metal sheets up to 4 mm in volume. Moreover, during operation, the material is subjected to high heating. And then special machines carry the process.

How does Auto Stamping work?

Automatic metal stamping according to customer's drawings allows you to create products of original configuration and shape in a single version and multi-batch. Thanks to automatic stamping, the parts are exactly the same. Similarly, the error can be a maximum of 0.05 mm.

Technological processes of metal stamping:

- The two pieces of sheet metal work in a straight or curved line.

- Notching. Subsequently, notches and cuts work on the metal without disturbing the overall integrity of the sheet.

- Simultaneously, the process is designed to work with the edges of the sheet. In addition, we peel off and waste the unnecessary parts.

- Punching. Bahagian Stamping Autoprocess with one or more holes. Hence, a pattern or pattern appears.

- Memotong . Gelung tertutup dibuat di dalam logam kosong dan serpihan keseluruhan dikeluarkan di sepanjangnya. Dalam kes ini, keseluruhan bahagian tetap ditutup.

- Ini adalah elemen hiasan yang membolehkan anda membetulkan penyelewengan pada kepingan logam dan melicinkan hujungnya.

- Kerucut muncul di permukaan logam, dengan kata lain, pecah, tetapi tanpa memotong lapisan logam.

Berapa Kos Bahagian Stamping Auto?

Soalan yang paling sering ditanya dan popular: "Berapa harga bahagian yang dicap?"

Untuk mengira kos pembuatan, anda perlu menambahkan komponen berikut:

- kos bahan + kos penghantaran / output berguna (pcs),

- kos dokumentasi reka bentuk + kos setem + kos pentauliahan / jangka hayat setem,

- Cost of medium and minor repair of a stamp + cost of spare parts. Moreover, it also includes / number of parts produced from service to service,

- Moreover, Shift cost / production rate.

- Information for customers

- Generally, mass production of metal products requires technology, raw materials, equipment and tooling.

- a) Technology - we will develop,

- b) raw materials - we will purchase,

- c) equipment - in stock,

- d) equipment - we will design and order.

- We work using your tooling and can make our own.

Technology development of auto stamping

This is the very first stage of Bahagian Stamping Auto. Furthermore, here the cost of the part depends. At this stage, you need to clearly understand your monthly need. Based on many years of experience, we will develop the most optimal manufacturing technology for the parts you need according to the criteria "need - terms - price - quality".

At the moment, for cold stamping of parts, you can select the required steel grade: cold-rolled, hot-rolled, cold-worked, stainless, etc. Moreover, there is cretion of waste during the production of steel products. Unlike foundries, this waste cannot be recycled locally and must be disposed of. Therefore, we include the costs of disposal in the price of the products.

- Metal waste from production can range from 3 to 80%.

- Material selection - steel grade Material selection - steel grade

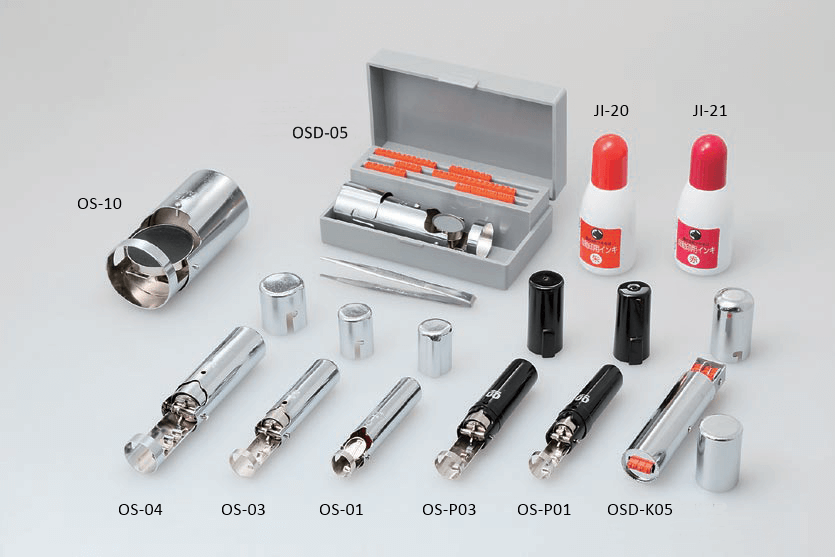

Equipment selection for Auto Stamping Parts

For the production of products based on the technology, equipment is selected taking into account:

- the steel grade

- the size of the workpiece

- the permissible force of the forging and

- Pressing equipment and the size of the finished product.

Production of documentation

For the manufacture of dies, design documentation is required - drawings. Similarly, the term for the development of design documentation is 3-4 weeks. The cost of a set of drawings for a stamp depends on the project.

Moreover, the development of design documentation is an important process. Therefore, we recommend checking cost of the forming equipment.

Tooling (stamp) manufacturing

For the manufacture of tooling (stamp), it is enough for us to receive a drawing or a sample of the part from you. Furthermore, you can allocate the cost of Bahagian Stamping Auto. For the manufacture of large batches of products on an ongoing basis, it is necessary to have at least two sets of dies. Subsequently, it is in order to ensure the required volumes of products. Moreover, it is to exclude downtime in the event of their breakdown.

How to even approximately understand the cost of Auto Stamping Parts?

Generally, the more complex the part, the larger the holes in it, the larger its size - the higher the cost of the stamp.

In addition, the term for making a stamp is from 1 month, the term for debugging a stamp is up to 2 weeks

Service stamps

Setem adalah peralatan yang mengalami beban operasi yang tinggi dan memerlukan penyelenggaraan berkala:

- Pemeriksaan

- penggantian bahagian

Secara amnya, pembaikan mati dan kecil dilakukan mengikut masa operasi dan jika perlu. Kemudahan Bahagian Stamping Auto menjalankan operasi di lokasi. Begitu juga, ia merangkumi:

- pembongkaran

- mencari kesalahan

- penggantian bahagian haus

- mengasah permukaan pemotongan

- demagnetisasi dan pemasangan

Kelebihan Descartes menumbuk pengimbas-penunjuk kedudukan

Meningkatkan kecekapan menumbuk:

- pengurangan kos perolehan

- Lebih-lebih lagi, peningkatan produktiviti (kelajuan kedudukan maksimum 50,000 mm / min).

Menyimpan bahan:

- 5 kali lebih banyak bahagian dari satu isipadu logam,

- Oleh itu, pengurangan sampah sebanyak 2.5 kali,

- Kemungkinan stamping dari tempat kosong tidak cair.

Penjimatan gaji sehingga 9 kali ganda:

- One person can serve 3 presses.

Reducing the price of stamps by 30%:

- Moreover, you can use 2-column and non-column dies,

- Stamps without guides, stepping knives and catchers.

Occupational Safety and Health:

- The presence of a person directly near the press is not required.

Brief Description of Auto Stamping Parts Scanner-Positioner Assemblies

- High strength frame

Bahagian Stamping Auto includes the high-strength, full-size frame. Similarly, it comes with high-tech welding. Moreover, it can withstand loads of up to 63 tons, ensuring stable and reliable operation.

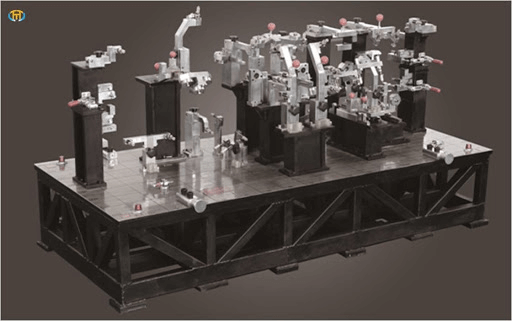

Stamp frame Descartes Stamp frame Descartes

- Technology of compensation of unevenness of the workpiece

Generally, the roller can freely follow the curvature of the sheet surface. To compensate for unevenness of the sheet during travel, the drive rollers have a vertical stroke.