Prototipagem Rápida

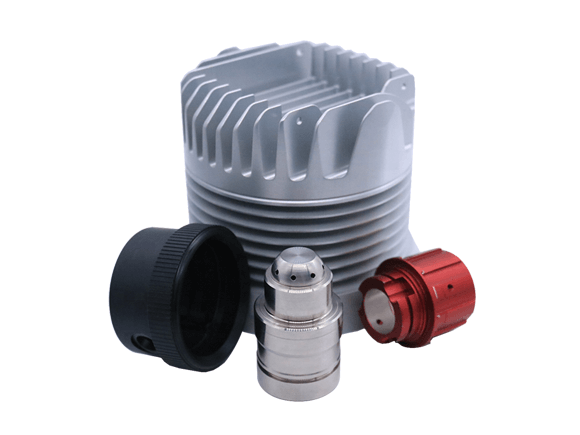

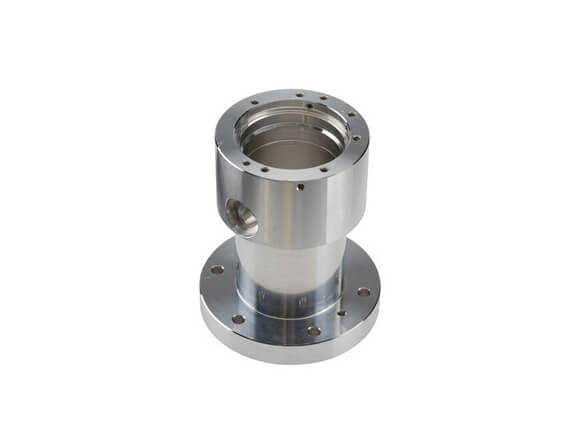

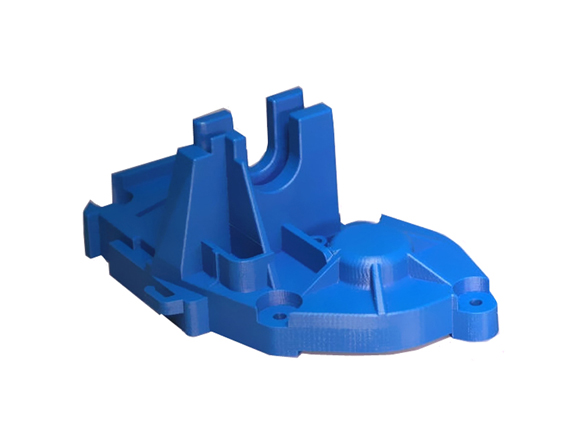

With the aid of computer-aided design or solid reverse method to obtain the prototype or part geometry and structure, and use this to build a digital model, and then use the computer-controlled mechanical and electrical integrated manufacturing system, the material is "three-dimensionally stacked" formed point by point and side by side. After necessary processing, it can meet the design requirements in terms of appearance, strength and performance, and achieve a rapid and accurate method of manufacturing prototypes or actual parts. Depending on the complexity of the part, this process typically takes 1 to 7 days.

Various rapid prototyping technologies entering the application field use different molding mechanisms, but their processing and manufacturing processes are similar, including the following three steps:

1. Produzir modelos de design CAD. Primeiro, um pacote de software de desenho auxiliado por computador (CAD) foi usado para gerar um modelo sólido tridimensional da peça. O software de modelagem de sólidos comumente usado atualmente inclui: Pro / E, UG-Ⅱ, Power Shape, etc. Também é possível obter as informações de descrição tridimensional da peça por meio de engenharia reversa.

2. Converta o modelo de projeto CAD 3D em formato STL (STL é o padrão da indústria de tecnologia RP). No processo de conversão, fatores como precisão de processamento, carga de trabalho de processamento e capacidade do arquivo devem ser considerados de forma abrangente.

3. Use the pre-processing software to convert the STL model into a processing file, that is, cut the STL model into 0.01 ~ 0.7mm thin layers according to different manufacturing processes. In this process, the coordinates and processing direction of the workpiece to be processed should be selected according to the performance requirements and the principle of minimizing the processing time, while taking into account the support during the processing of the workpiece.