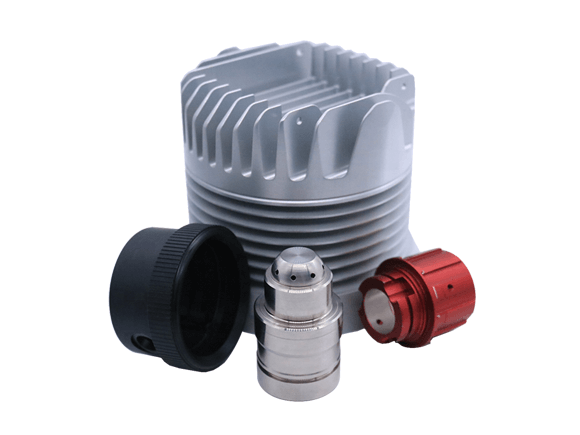

Vinnige prototipering

Met behulp van rekenaargesteunde ontwerp of soliede omgekeerde metode om die prototipe of deelmetrie en struktuur te verkry, en gebruik dit om 'n digitale model te bou, en gebruik dan die rekenaarbeheerde meganiese en elektriese geïntegreerde vervaardigingstelsel, die materiaal is "drie -dimensioneel gestapel "gevorm punt vir punt en langs mekaar. Na die nodige verwerking kan dit voldoen aan die ontwerpvereistes ten opsigte van voorkoms, sterkte en werkverrigting en 'n vinnige en akkurate metode bereik om prototipes of werklike onderdele te vervaardig. Afhangend van die kompleksiteit van die onderdeel, duur hierdie proses gewoonlik 1 tot 7 dae.

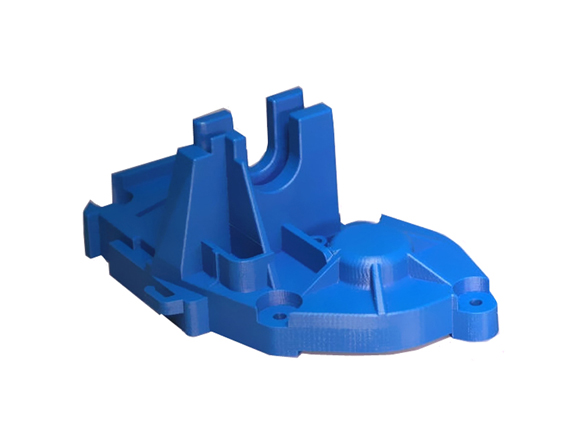

Verskeie vinnige prototiperingstegnologieë wat die toepassingsveld betree, gebruik verskillende vormmeganismes, maar die prosesserings- en vervaardigingsprosesse daarvan is soortgelyk, insluitend die volgende drie stappe:

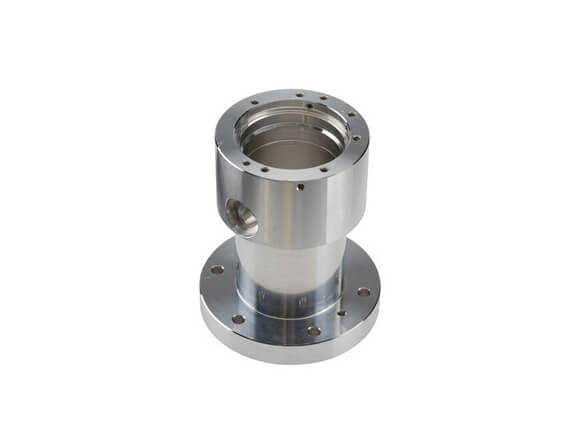

1. Produce CAD design models. First, a computer aided design (CAD) software package was used to generate a three-dimensional solid model of the part. Currently commonly used solid modeling software includes: Pro / E, UG-Ⅱ, Power Shape, etc. It is also possible to obtain the three-dimensional description information of the part through reverse engineering.

2. Convert the 3D CAD design model into STL (STL is the RP technology industry standard) format. In the conversion process, factors such as processing accuracy, processing workload and file capacity must be considered comprehensively.

3. Use the pre-processing software to convert the STL model into a processing file, that is, cut the STL model into 0.01 ~ 0.7mm thin layers according to different manufacturing processes. In this process, the coordinates and processing direction of the workpiece to be processed should be selected according to the performance requirements and the principle of minimizing the processing time, while taking into account the support during the processing of the workpiece.