Understanding China CNC machining

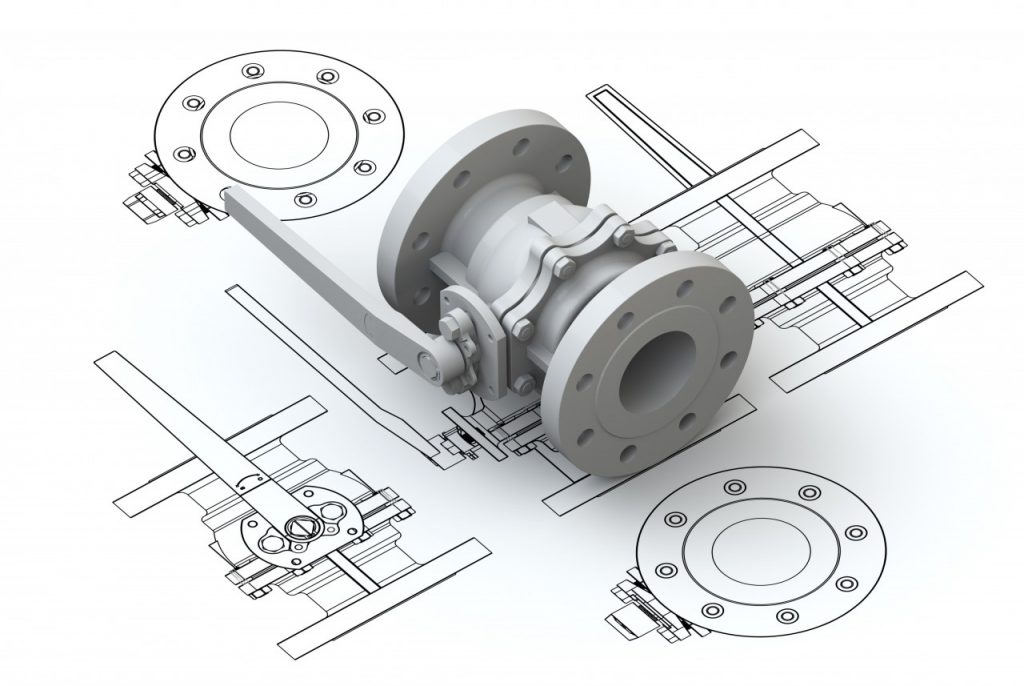

18/04/2020Computer numerical control China CNC machining is an automated manufacturing method that uses cutting tools to selectively remove material from the blank until a desired shape is obtained. It works by converting the digital model of the part into a series of computer instructions that control the movement of the machining tool to achieve the desired output. Because it is computer controlled, compared with other common manufacturing methods,China CNC machining can provide a higher level of versatility, efficiency, and accuracy. This makes it a popular manufacturing choice for a wide range of industries and applications.

Processo diverso

Existem muitos tipos de máquinas- ferramenta usinagem CNC incluem:

Fresamento CNC A fresagem

CNC usa uma ferramenta rotativa multiponto para remover o excesso de material da peça quando a peça é alimentada na ferramenta de corte. Ferramentas rotativas podem ser movidas ao longo de diferentes eixos com alta precisão para criar peças com geometrias complexas. Protótipos ou peças finais podem ser fabricados rapidamente com alta precisão e repetibilidade.

Usinagem CNC vertical

Vertical CNC machining is a form of milling where the spindle axis and related cutting tools are oriented vertically relative to the machine bed. The cutting tool points downward from the tool holder and is usually used to cut the top of the workpiece surface.

Horizontal CNC machining

Horizontal China CNC machining (also a form of milling) uses a tool mounted on a horizontal spindle. The tool comes out from the side of the tool holder and crosses the side of the workpiece surface, so that the chips fall from the table.

Different processing 3ERP

CNC turning

In contrast to milling, CNC turning uses a single point milling cutter to remove material from a rotating workpiece fixed in a chuck. CNC lathes or lathes rotate the workpiece along a linear motion to feed the tool, removing excess material to produce a highly accurate round or tubular shape. Like milling, turning can quickly create prototypes and final parts.

Wire electrical discharge machining (EDM)

Wire cutting machine tools are used to cut conductive materials. The live wire fixed between the two mechanical guides serves as one electrode, and the workpiece being cut serves as the second electrode. The discharge generated between the welding wire and the workpiece generates sparks, which cut the material from the workpiece. Since no cutting force is involved, the wire-cut electric discharge machine is very suitable for producing small and delicate parts.

metal processing

Metal CNC machining uses computer-controlled cutting tools to selectively remove material from metal workpieces and shape it into the desired shape. Many common metals are compatible with CNC machining processes such as aluminum, copper, and steel.

Plastic processing

usinagem CNC can also be used to create custom-designed components and products from various types of plastics (including acrylic, polycarbonate, polypropylene, and many other plastics). Plastic processing may involve one or more of the above processes, which create the design shape by selectively cutting material from the plastic workpiece.

Usinagem CNC vertical

Usinagem CNC vertical

Horizontal CNC machining

Horizontal CNC machining

CNC turning

CNC turning