Comprensión del mecanizado CNC en China

2020-04-18Control numérico por computadora El mecanizado CNC de China es un método de fabricación automatizado que utiliza herramientas de corte para eliminar selectivamente el material de la pieza en bruto hasta obtener la forma deseada. Funciona convirtiendo el modelo digital de la pieza en una serie de instrucciones informáticas que controlan el movimiento de la herramienta de mecanizado para lograr el resultado deseado. Debido a que está controlado por computadora, en comparación con otros métodos de fabricación comunes, el mecanizado CNC de China puede proporcionar un mayor nivel de versatilidad, eficiencia y precisión. Esto lo convierte en una opción de fabricación popular para una amplia gama de industrias y aplicaciones.

Diverse process

There are many types of China CNC machine tools, and each machine tool has its own unique advantages and functions. Depending on the function of a particular machine, the number of axes and the direction of the cutting tool, different machining possibilities can be realized. Some of the most common China CNC machining processes include:

CNC milling

CNC milling uses a rotating multi-point tool to remove excess material from the workpiece when the workpiece is fed into the cutting tool. Rotating tools can be moved along different axes with high precision to create parts with complex geometries. Prototypes or final parts can be manufactured quickly with high accuracy and repeatability

Vertical CNC machining

Vertical CNC machining is a form of milling where the spindle axis and related cutting tools are oriented vertically relative to the machine bed. The cutting tool points downward from the tool holder and is usually used to cut the top of the workpiece surface.

Horizontal CNC machining

Horizontal China CNC machining (also a form of milling) uses a tool mounted on a horizontal spindle. The tool comes out from the side of the tool holder and crosses the side of the workpiece surface, so that the chips fall from the table.

Different processing 3ERP

CNC turning

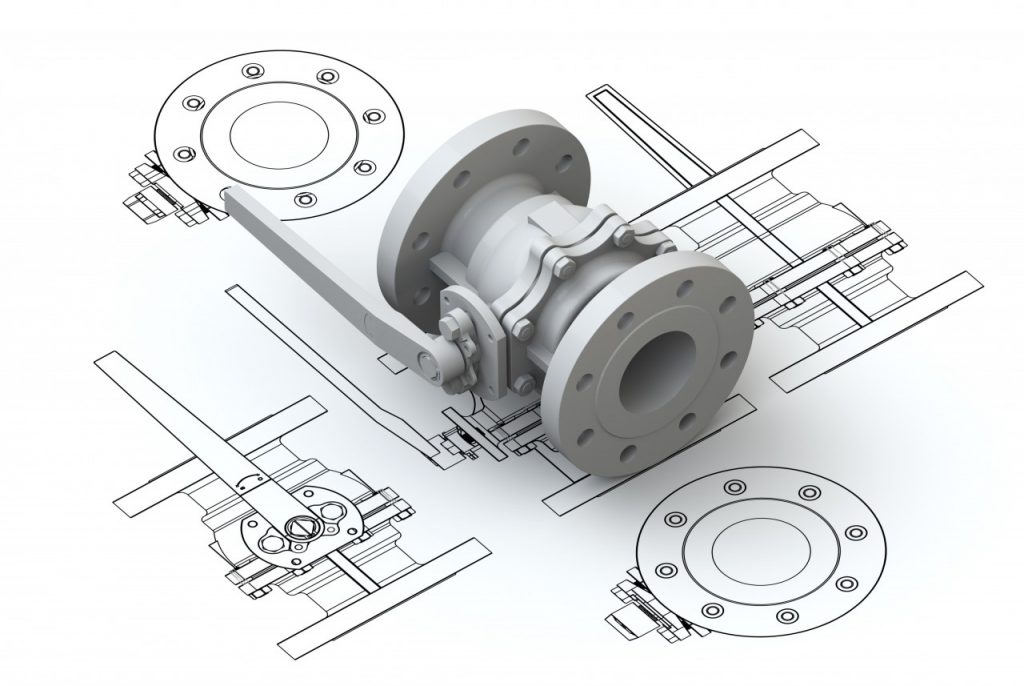

In contrast to milling, CNC turning uses a single point milling cutter to remove material from a rotating workpiece fixed in a chuck. CNC lathes or lathes rotate the workpiece along a linear motion to feed the tool, removing excess material to produce a highly accurate round or tubular shape. Like milling, turning can quickly create prototypes and final parts.

Wire electrical discharge machining (EDM)

Wire cutting machine tools are used to cut conductive materials. The live wire fixed between the two mechanical guides serves as one electrode, and the workpiece being cut serves as the second electrode. The discharge generated between the welding wire and the workpiece generates sparks, which cut the material from the workpiece. Since no cutting force is involved, the wire-cut electric discharge machine is very suitable for producing small and delicate parts.

metal processing

Metal CNC machining uses computer-controlled cutting tools to selectively remove material from metal workpieces and shape it into the desired shape. Many common metals are compatible with CNC machining processes such as aluminum, copper, and steel.

Plastic processing

China CNC machining can also be used to create custom-designed components and products from various types of plastics (including acrylic, polycarbonate, polypropylene, and many other plastics). Plastic processing may involve one or more of the above processes, which create the design shape by selectively cutting material from the plastic workpiece.

Vertical CNC machining

Vertical CNC machining

Horizontal CNC machining

Horizontal CNC machining

CNC turning

CNC turning