Understanding China CNC machining

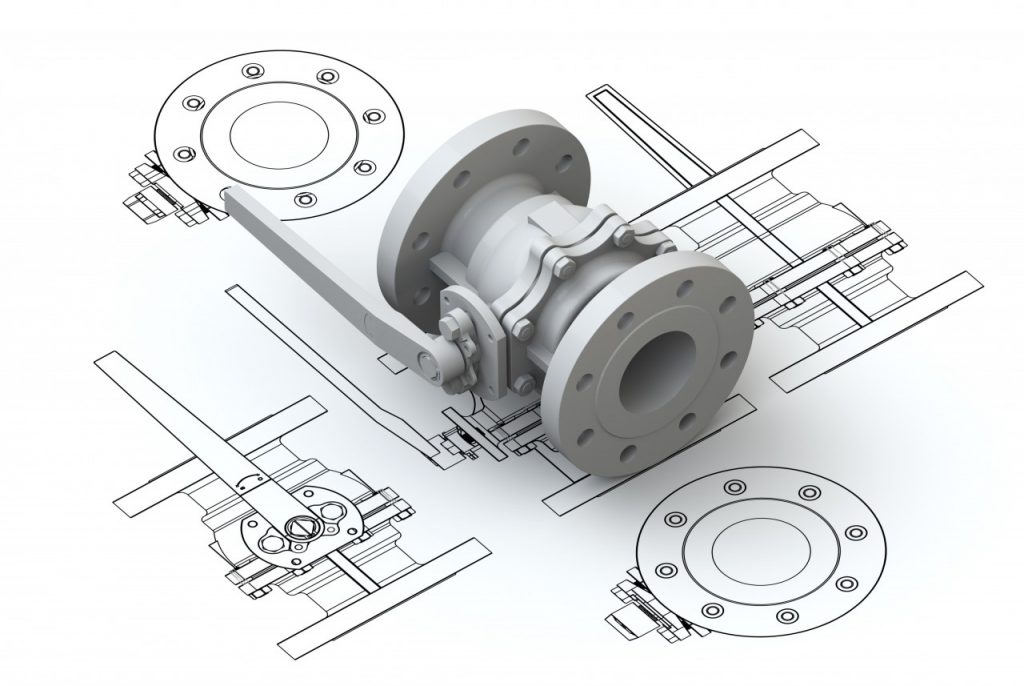

2020-04-18Computer numerical control China CNC machining is an automated manufacturing method that uses cutting tools to selectively remove material from the blank until a desired shape is obtained. It works by converting the digital model of the part into a series of computer instructions that control the movement of the machining tool to achieve the desired output. Because it is computer controlled, compared with other common manufacturing methods,China CNC machining can provide a higher level of versatility, efficiency, and accuracy. This makes it a popular manufacturing choice for a wide range of industries and applications.

Diverse process

There are many types of China CNC machine tools, and each machine tool has its own unique advantages and functions. Depending on the function of a particular machine, the number of axes and the direction of the cutting tool, different machining possibilities can be realized. Some of the most common China CNC machining processes include:

CNC milling

CNC milling uses a rotating multi-point tool to remove excess material from the workpiece when the workpiece is fed into the cutting tool. Rotating tools can be moved along different axes with high precision to create parts with complex geometries. Prototypes or final parts can be manufactured quickly with high accuracy and repeatability

Vertical CNC machining

Die vertikale CNC-Bearbeitung ist eine Form des Fräsens, bei der die Spindelachse und die zugehörigen Schneidwerkzeuge vertikal relativ zum Maschinenbett ausgerichtet sind. Das Schneidwerkzeug zeigt vom Werkzeughalter nach unten und wird normalerweise zum Schneiden der Oberseite der Werkstückoberfläche verwendet.

Horizontale CNC-Bearbeitung Bei der

horizontalen China-CNC-Bearbeitung (auch eine Form des Fräsens) wird ein auf einer horizontalen Spindel montiertes Werkzeug verwendet. Das Werkzeug kommt von der Seite des Werkzeughalters heraus und kreuzt die Seite der Werkstückoberfläche, so dass die Späne vom Tisch fallen.

Unterschiedliche Verarbeitung 3ERP

CNC-Drehen

In contrast to milling, CNC turning uses a single point milling cutter to remove material from a rotating workpiece fixed in a chuck. CNC lathes or lathes rotate the workpiece along a linear motion to feed the tool, removing excess material to produce a highly accurate round or tubular shape. Like milling, turning can quickly create prototypes and final parts.

Wire electrical discharge machining (EDM)

Wire cutting machine tools are used to cut conductive materials. The live wire fixed between the two mechanical guides serves as one electrode, and the workpiece being cut serves as the second electrode. The discharge generated between the welding wire and the workpiece generates sparks, which cut the material from the workpiece. Since no cutting force is involved, the wire-cut electric discharge machine is very suitable for producing small and delicate parts.

metal processing

Metal CNC machining uses computer-controlled cutting tools to selectively remove material from metal workpieces and shape it into the desired shape. Many common metals are compatible with CNC machining processes such as aluminum, copper, and steel.

Plastic processing

China CNC machining can also be used to create custom-designed components and products from various types of plastics (including acrylic, polycarbonate, polypropylene, and many other plastics). Plastic processing may involve one or more of the above processes, which create the design shape by selectively cutting material from the plastic workpiece.

Vertical CNC machining

Vertical CNC machining

Horizontale CNC-Bearbeitung Bei der

Horizontale CNC-Bearbeitung Bei der

CNC-Drehen

CNC-Drehen