Aluminium Extrusion manufacturer: A Guide to Extrusion

2020-08-25Aluminum Extrusion manufacturer: A Step by Step Extrusion Process

In recent times, there has been an increased demand for Aluminium Extrusion in product manufacturing and design. This led to an increase in the demand for a professional and reliable Aluminium Extrusion manufacturer. Technavia presented a report showing that there would be an annual growth rate of almost 4%.

In case, you are unaware of this manufacturing process, you are in the right place. In the course of this article, we will talk about Aluminium Extrusion in detail. So, without any further delay, let us get started!

A Guide on Aluminium Extrusion

What is Aluminium Extrusion?

It is a process that forces an aluminum alloy material through a die while using some specific cross-sectional profile. The manufacturer uses a powerful ram to pus the aluminum through the die. Due to the intense pressure, the aluminum comes out of the die opening.

When the aluminum comes out of the die’s front, it has the same shape as that of the die. A runout table then pulls out the aluminum. Aluminium Extrusion is easy to understand the process, especially at the fundamental level.

You can link the force applied to push the aluminum via the die’s front as to that of squeezing a tube to get the ingredient out. The substance present inside the tube would take the same shape as the opening of the tube after you apply pressure to it.

So, it means that aluminum shape would depend upon the opening of the die. For round shape, you would require round opening, for square, square opening, and so on.

Shapes to be Extruded

You categorize the extruded shapes in three different categories.

1. Solid

Solid shapes do not have enclosed openings or voids. Angle, beam, or the rod are common examples that fall under this particular category.

2. Hollow

Hallow usually comes with one or more voids. For instance, a rectangular tube or a square tube.

3. Semi-hallow

These shapes generally have a void that is partially enclosed. For example, the “C” channel having a narrow gap.

Extrusion is popular among numerous industries including the energy, aerospace, electronics, automotive, architecture, and several other industries. You can achieve even extremely complex shapes by using multiple extrusion processes.

The Aluminium Extrusion Process

Below, we have explained the Aluminium Extrusion process in ten steps.

Step 1: Preparing and Moving the Extrusion Die

For starters, an Aluminium Extrusion manufacturer would use H13 steel for the machining a round-shape die. Of course, some manufacturers would already have the desired shape. In that case, they would simply pull it out from their warehouse.

Khuôn cần được làm nóng trước từ 450 đến 500 độ C. Điều này không chỉ giúp tối đa hóa tuổi thọ của khuôn mà còn đảm bảo kim loại chảy đều. Sau khi làm nóng khuôn, bạn có thể nạp khuôn vào máy ép đùn.

Bước 2: Làm nóng phôi nhôm trước khi đùn

Bước tiếp theo là làm nóng phôi nhôm. Về cơ bản nó là một khối hợp kim nhôm rắn hình trụ. Các nhà sản xuất chiết xuất phôi tạo thành một khúc gỗ dài hơn bằng vật liệu hợp kim nhôm. Bạn nên làm nóng trước trong lò nướng. Nhiệt độ cần từ 400 đến 500 độ C.

Việc làm nóng phôi sẽ không làm nó tan chảy hoàn toàn. Tuy nhiên, nó sẽ làm cho nó đủ dẻo để tạo ra năng suất cho quá trình ép đùn.

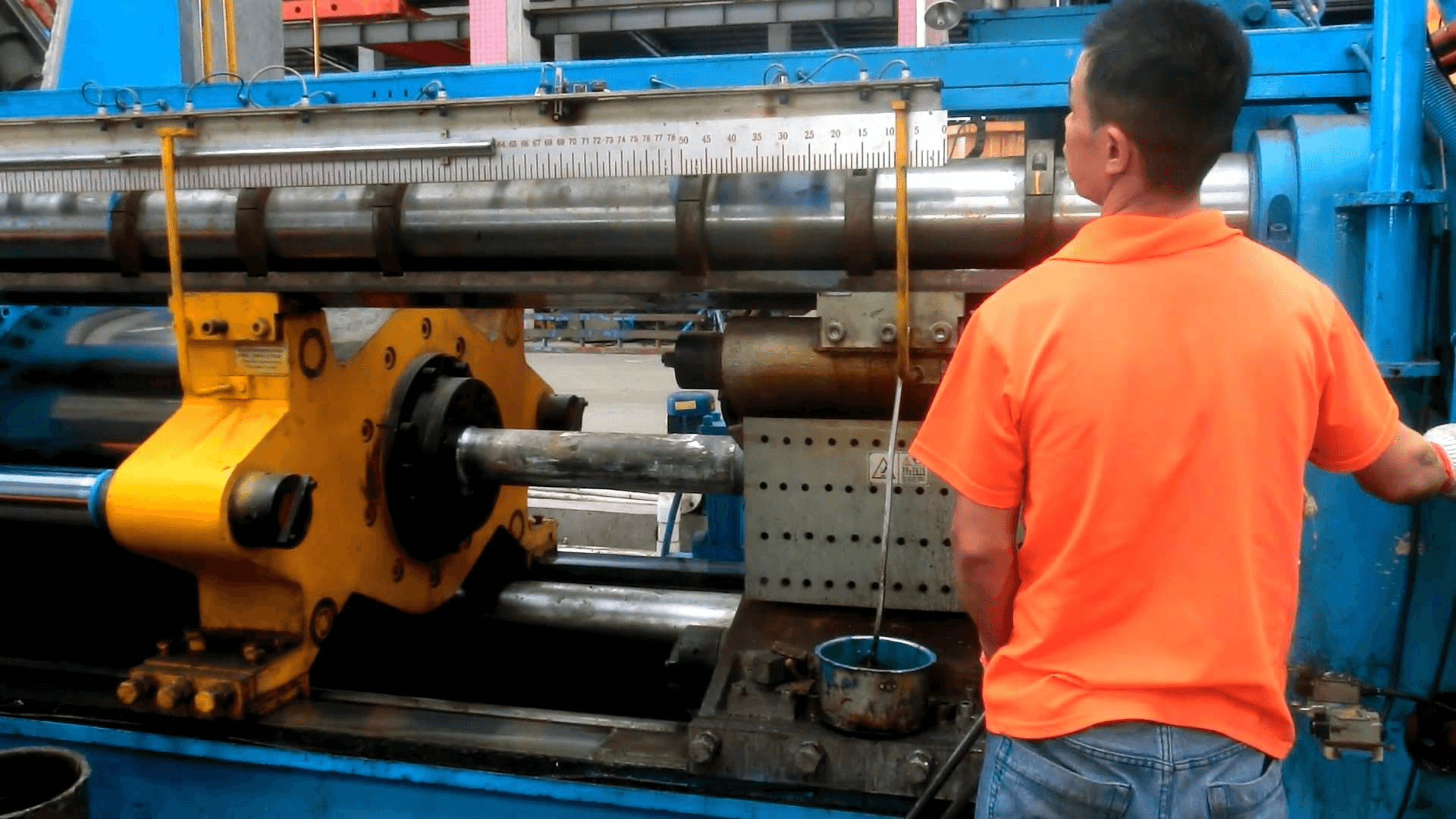

Bước 3: Chuyển đùn sang máy ép phôi

Sau khi bạn làm nóng phôi theo yêu cầu, về mặt cơ học, phôi sẽ được chuyển đến máy ép đùn. Tuy nhiên, việc bôi chất giải phóng hoặc chất bôi trơn lên phôi là quan trọng. Bước này cần thực hiện trước khi nạp phôi vào máy ép.

Ngoài ra, điều quan trọng là phải áp dụng cùng một chất giải phóng cho ram đùn. Làm như vậy sẽ đảm bảo rằng ram và phôi không dính vào nhau.

Bước 4: Đẩy phôi trong thùng chứa

Sau khi chuyển phôi sang máy ép đùn, đã đến lúc tạo lực ép. Chiếc ram sẽ tạo ra khoảng 15.000 tấn áp lực lên phôi thép dễ uốn. Việc áp dụng lực ép phôi vào thùng chứa máy ép đùn.

Vật liệu sẽ nở ra và dần dần lấp đầy thành thùng chứa.

Bước 5: Vật liệu ép đùn ra khỏi khuôn

Even after the material fills the container, the ram is still applying pressure. It means that now the material is pushed against the extrusion die. Due to continuous pressure, the aluminum material would go through the die’s opening.

When it comes out from the opening of the die, it is in the exact shape as that of the die opening. This means, that you have achieved your desired shape so far.

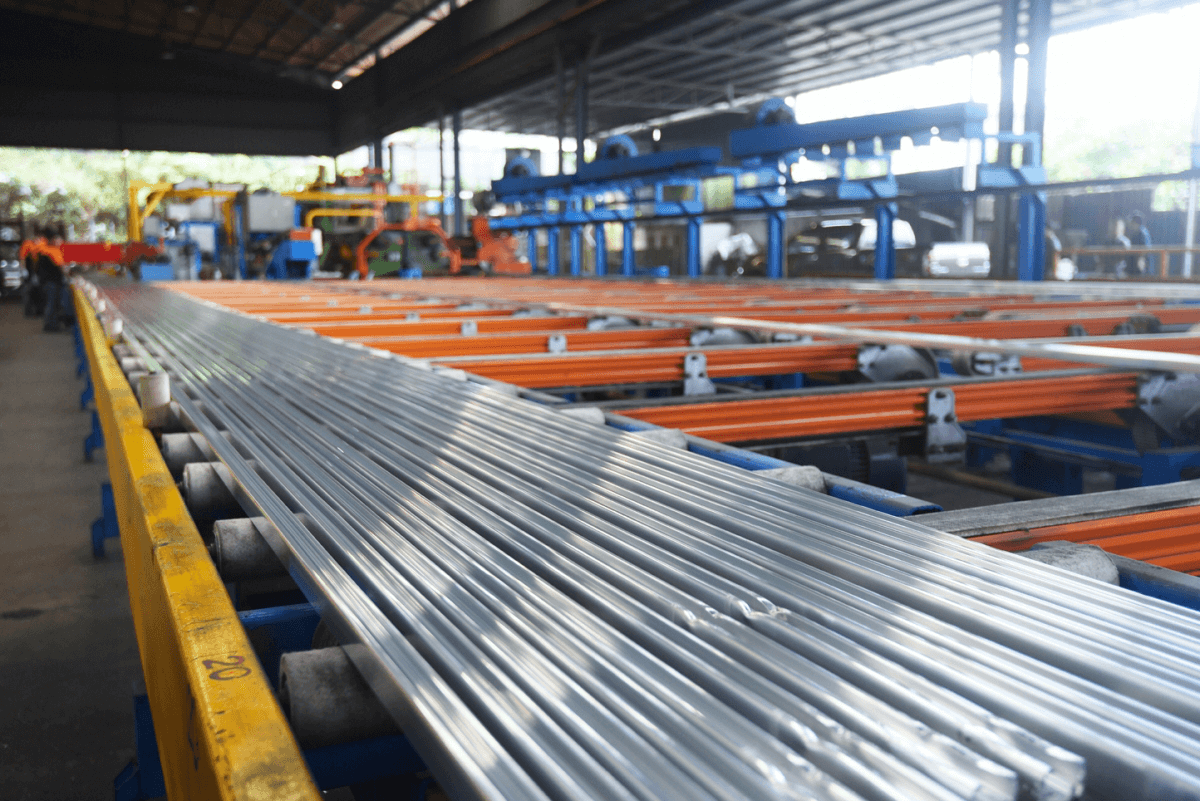

Step 6: Quenching and Runout Table

When the extrusion comes out from the die’s front, a puller holds onto it. This puller is then responsible for guiding it along with the run-out table. The speed of the table would match the speed at which the extrusion is coming out of the press.

With the run-out table movement, the profile is quenched. To ensure its sturdiness, it needs to be cooled uniformly. Aluminium Extrusion manufacturer either uses fans located above the table or they rely on water baths.

Step 7: Extrusion Shearing

After the extrusion has reached its full table length, it is not time to sheared it away from the extrusion process. For this particular purpose, manufacturers use a hot saw. The saw would separate the particular extrusion from the extrusion process.

NOTE: Temperature is an extremely important aspect of the extrusion process. You need to keep a close check on it at every stage of the extrusion process.

Even though you quench the extrusion after it leaves the press, it still requires time to fully cool down.

Step 8: Extrusion Cooling at Room Temperature

After the shearing takes place, it is time to transfer the extrusion from the run-out table to the cooling table. This process would take place mechanically. Now the manufacturer would wait for the profile to reach room temperature before shifting it to some other place.

After they cool down, it is important to let them stretch.

Step 9: Moving Extrusion to Stretcher

Sometimes, there is a certain twisting that occurs in the profile. As a professional Aluminium Extrusion manufacturer, you would have to work on it. In order to correct the problem, you move the table length extrusion on to a stretcher.

Every profile is gripped from both sides. It would mechanically be pulled until it reaches the desired specifications.

Step 10: Sawed According to Specifications

Now that the table length extrusions are fully cooled and they are straight as well, it is time to transfer them to the saw table.

Here, these extrusions are sawed according to the length. In general, the length ranges from eight to twenty-one feet.

NOTE: The properties of extrusion at this particular stage are similar to that of the T4 temper. After sawing, it is possible to age the extrusion to T5 or T6. In order to do so, you would have to move them to an aging oven.

The Final Touches

After the completion of extrusion, it is possible to enhance the properties of the profiles by giving them heat treatments. To enhance the finished look of the extrusions, Aluminium Extrusion manufacturer uses different finish types.

Tuy nhiên, những kết thúc này cần phải được thực hiện xử lý nhiệt. Để đưa sản phẩm đùn đến kích thước cuối cùng, chúng cần trải qua các hoạt động chế tạo khác nhau.

Cải thiện tính chất cơ học

Có thể tăng cường độ bền kéo và khả năng chịu ứng suất của các hợp kim trong dòng 7000, 6000 và 2000. Để có được những cải tiến này, điều quan trọng là phải đưa các cấu hình vào lò nướng. Những xử lý gia nhiệt này sẽ đưa các hợp kim đến nhiệt độ T5 hoặc T6.

Tăng cường bề mặt

Có rất nhiều hoạt động hoàn thiện mà các cấu hình nhôm sẽ trải qua. Cải tiến bề mặt không chỉ cải thiện hình thức tổng thể của nhôm mà đồng thời, nó cũng cải thiện tính chất ăn mòn của nó.

For instance, when you anodize the aluminum, it would result in the natural occurrence of the oxide layer. Thus, resulting in the thickening of the metal. Also, the process would enhance the corrosion resistance of the profile. In addition, the metal would become more resistant to wear.

Likewise, it would result in a porous surface, it means that the surface would accept different colors. The surface emissivity would be enhanced as well.

There are some other finishing processes available as well. Some of them are listed below:

- Sandblasting

- Powder Coating

- Painting

- Sublimation

Tóm lược

Aluminium Extrusion is a process that manufacturers use to create components and parts having certain cross-sectional profiles. To enhance both the properties and appearance of the aluminum, the manufacturer uses different mechanical and surface enhancement processes.

Các Aluminium Extrusion manufacturer also uses certain fabrication process to acquire the final dimensions of the product. After all, their objective is to achieve high-quality aluminum parts.

In case, you are looking for an Aluminium Extrusion supplier or manufacturer, you can reach out to us. We will provide you with all that you are looking for.