CNC-bewerking Deellys 2020: Hoe werk cnc-masjien?

2020-07-06Belangrikste uitdagings in die werk van cnc-masjiene

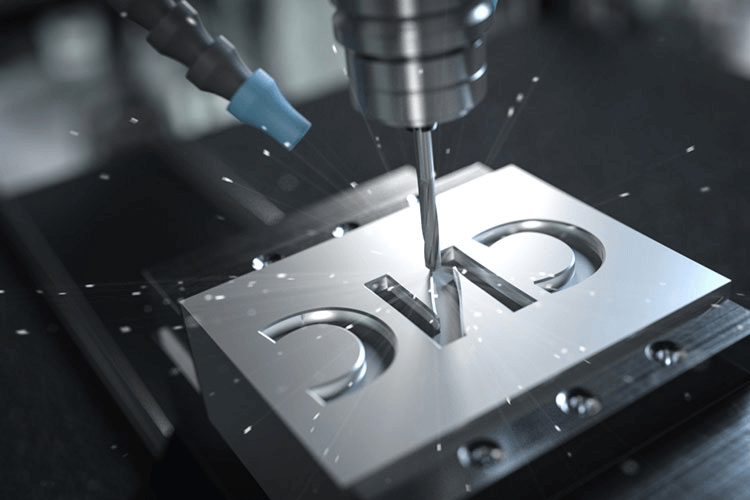

Wat is CNC-bewerking?

CNC bewerking Deel beheer is a very modern method. It consists of making objects of various shapes using new machining technologies. As its name suggests, this process uses digital controls.

Met ander woorde, dit is 'n rekenaar wat die opdragte stuur om die gereedskap oor die aanvanklike massa te skuif om die gewenste vorm te verkry. CNC-bewerking is 'n aftrekproses waarin 'n onderdeel geskep word deur materiaal uit 'n beginmassa te verwyder.

Dit gebruik masjiengereedskap. Soos:

- Milling machines and

In the case where the machine tool ordered is a milling machine, we speak of CNC milling. We rather talk about CNC turning in the case of a lathe. For online CNC-bewerkingsonderdeel, a 3D file is sent to the computer.

It is saved on the control computer which will interpret it into a set of instructions, that is to say a program. It is this program which defines the axis of rotation of the milling cutter in CNC milling.

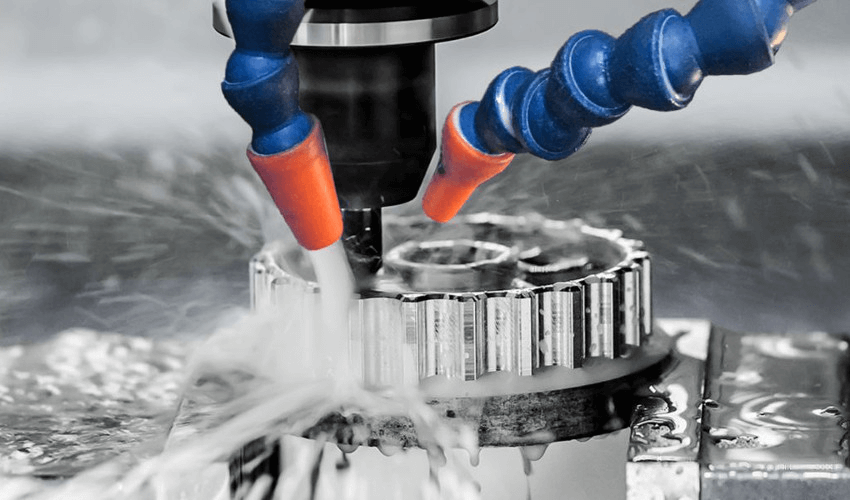

The automatic milling machines used often have 3 or 5 different axes of rotation. It can be changed according to the instructions received from the computer.

The process remains the same for CNC turning. The only difference is that it is the axis of rotation of the part that changes, not that of the lathe. Modern CNC machines use both tools.

CNC Machining Part Advantages

The main advantage of this process is that it is quick and inexpensive when it comes to manufacturing around ten parts. However, CNC-bewerkingsonderdeel has a cost limit when it comes to large-scale production. This is due to the importance of economies of scale.

How has machining changed over time?

It is estimated that the first use of a machining process dates back several centuries before Christ. The first object manufactured by machining, never discovered, is a bowl discovered in Italy.

It was machined in 700 BC. However, it was not until the 18th century, 25 centuries later, that the first attempt to automate machining was made.

The machines, at that time were mechanical and turned with the vapor. It was not until the last century, in the 1940s, that the first programmable machine was developed at MIT.

Sy het CNC-bewerkingsonderdeel elke beweging met behulp van ponskaartjies. Met die vermeerdering van rekenaars in die vyftiger- en sestigerjare is CNC-bewerking regtig gebore en begin.

Deesdae is die proses baie meer gevorderd in tegnologie. Met die internet is dit nou moontlik om CNC-bewerking aanlyn te doen. Numeries beheerde masjiene is nou komplekse en robotstelsels. Dit het multi-gereedskap en multi-as kapasiteit.

Rol van 3D-drukkers in CNC-bewerkingsdeel

CNC bewerking Deel is die beheer van masjiengereedskap met behulp van 'n rekenaar. Dit bestaan sedert die 70's van die 20ste eeu as 'n evolusie van NC.

Dit is nie noodwendig aan rekenaars gekoppel nie. Maar dit was op ander maniere om masjiengereedskap te beheer. Dit dateer in die 1940's en 1950's.

Vir diegene wat hierdie tipe bewerking beskou as iets baie ingewikkelds, gereserveer vir die bedryf. Miskien is 'n masjien onder die CNC-masjiene wat in klein werkwinkels ontwikkel is, bekend met 3D-drukkers.

Om CNC-bewerkingsonderdele met ' n 3D-drukker te maak, moet u die stappe van die CNC volg.

- ontwerp die onderdeel met behulp van sagteware om 'n 3D-model te skep

- die bewegings van die asse te spesifiseer

- Die vordering van die gereedskapvorming, ens.

- haal die kode van hierdie ontwerp uit

- en dra dit in 'n lêer oor na die drukknop en aktiveer dit,

- Kontroleer of die onderdeel korrek vervaardig is.

Voor NC- en CNC-bewerkingsdeel

Die CNC-bewerking en daarna die CNC het dit moontlik gemaak om die masjiengereedskap te beheer. Dit moes tot dan toe plaasvind om 'n onderdeel te masjineer.

For example, before CNC and CN machining, the drilling of a tube was carried out by placing the tube.

CN machining was an advance in these directions. Because it made it possible to control the machine tool using a strip.

In this way, the intervention of the person at each stage was not necessary. He could accomplish other tasks. Meanwhile, the CNC bewerking Deelproductivity increased enormously.

Before numerical control, the machining processes included an important part of manual manipulation. Currently, some isolated operations are carried out manually, with few parts.

Subsequently, this brought several advantages.

Main advantages of CNC Machining Part

Improved automation in digital control without a computer. This means that the intervention of the person at each stage can be reduced.

Although some manual action always takes place for specific tasks, such as repair and work on prototypes. This increases production at the same time. Since CNC machines can operate 24 hours a day.

Greater precision and consistency of the parts obtained. Current CNC machines have amazing precision and repeatability specifications.

It can easily make two, ten or a thousand identical pieces. It was fundamental in mass production of CNC-bewerkingsonderdeel.

Greater flexibility, as machine tools controlled by a computer program new CNC bewerking Deelrequires a little modification. This allows rapid changes to any type of part.

Main challenges of CNC Machining Part

- Hoë bedryfskoste: CNC-masjiene verminder die aantal benodigde werkers in 'n vervaardigingsaanleg. Die gebruik daarvan is duurder. Die koste verbonde aan die gebruik van masjiene neem egter geleidelik af.

- Behoefte aan opleiding: die veralgemening van CNC-bewerking het aanvanklik baie werkloosheid tot gevolg gehad. Dit verminder die behoefte aan werkers. Met voldoende opleiding genereer hierdie stelsel egter nuwe gespesialiseerde werksgeleenthede. Aangesien dit CNC-masjiengereedskap, programmeerders en onderhoudspersoneel benodig. Gereedskap en opleiers om te leer hoe dit werk.

CNC-bewerking

Eintlik kan u met CNC-bewerking byna alles doen wat voorheen met die hand gedoen is. Plaas die boor op die as, aktiveer dit, masjineer dit en stop die as.

Once the machine tool has been digitally configured and put into service, operator intervention is minimal. It is even possible to automate the part loading process.

However, the operator's task is still necessary to perform checks of the measurements and adjustments. So that the CNC bewerking Deelcontinues to function properly.

CNC machine control

The CNC program must be interpreted by the control of the machine tool. It will activate the series of orders in a sequential order.

Step by step, causing the movement of the tool. This check also performs other functions. Such as checking to confirm that the program is working well.

CAM system

CAM is computer assisted machining. There are various software programs that simplify the programming process. In this way, the CNC programmer simply specifies in the software the machining operations to be performed automatically.

Role of metal extraction in CNC-bewerkingsonderdeel

Metal extraction industry: is the industry responsible for giving the final form to semi-finished parts. Tube cutting is an example of this type of industry. And the automotive industry is an example of its recipients.

This industry was one of the ones that more manual machines used several decades ago. But today, the CNC versions of these same machines are fully developed.

The most used machine tools in the CNC bewerking Deelindustry are:

The CNC laser and the CNC plasma: give their final shape to plates. In the tube industry, the laser is specially used for machining complex shapes with a smooth finish.

- CNC punching machines:they make holes of all sizes in plates or other parts. In tubes, it can be used in the furniture manufacturing industry. Because the holes in the tubes allow the introduction of screws.

- CNC presses:used to fold the plate or another piece to give the final shape. In the case of tubes, it can be used to widen and flatten one end.

- CNC jigs:they are sometimes coupled to shearing machines to control the length of the plate.

In all these types of machines, the intervention of the CNC bewerking Deelis minimal. Its task is centered on the design of the work.

CNC Machining Part Conclusion

CNC-bewerkingsonderdeel is used not only in the metal industry, but also in the wood industry. So CNC technology is also used in the number of letter and engraving systems. There are also CNC machines for the electrical industry. Such as:

- The CNC winders

- CNC location machines and

- CNC welding machines.

In fact, certain types of CNC machines can be found in one way or another in any industry. Advances in the manufacturing sector are largely due to advances in CNC technology.