Wrywingsroei (FSW) Voor- en nadele: (FSW vs Rotary Welding)

2020-11-23Wrywinglas: beginsel, voordele en toepassings

Friction Stir Welding (FSW) is 'n soort druksweis. Hier kom die smelt van die oppervlaktes deur die meganiese energie van die wrywingskrag van die dele in termiese energie om te skakel.

Wrywingsroei (FSW) - wat is dit?

Wrywing roersweis is 'n tipe verbinding wat druk gebruik. Dit beteken dat die dele wat gesweis moet word, sal verhit word as gevolg van wrywing teen mekaar. Die een deel bly stil, terwyl die ander draai, waardeur die onderdele met mekaar verbind kan word.

This method is quite new. And, perhaps, not all specialists or amateur welders had time to get acquainted with such welding technology. Therefore, we will read the principles of its operation, advantages, disadvantages, parameters, features and varieties of this method in more detail.

In this article we will look at:

- Hoe Wrywingstrooisweis (FSW)works?

- What types of technology exist?

- What are the advantages and disadvantages of friction welding?

Application and types of Friction Stir Welding (FSW)

Generally, friction welding is commonly applicable in the following operations:

- compounds of metals and alloys with a melting point of up to 1800 degrees

- welding flat parts of the same thickness at a turned angle

- longitudinal pipe welding

- making bolts

- Replacing soldering of small parts with machined surfaces.

Friction welding is suitable for joining contaminated parts, since it does not require their preliminary cleaning. Moreover, we remove the oxide film and grease at the beginning of mutual friction of the surfaces.

There are the following main types of friction welding:

- oscillatory (linear)

- with stirring, with continuous drive

- radial

- orbital, inertial

Advantages and disadvantages of the method

The advantages of Wrywingstrooisweis (FSW) are:

- lower energy consumption compared to other types of welding

- Moreover, a small number of defects

- uniform structure of the weld

- the ability to accurately control the process

- Small amount of harmful emissions

- Hence, high metal utilization rate

- The ability to automate the process.

- Low requirements for surface cleanliness. There is no need to clean the surface of the parts to be welded. The side surfaces may also be uncleaned. Similarly, this significantly saves time spent on auxiliary operations.

- Possibility of welding various metals. The welding process allows welding both alloys and metals of the same name and dissimilar alloys. Furthermore, other welding methods are useless here. For example, it is possible to weld steel to aluminum, copper; aluminum with copper, titanium and so on.

- Hygienic process. The welding process compares favorably with the absence of ultraviolet radiation.

Disadvantages of the Friction Stir Welding (FSW):

- Friction Stir Welding (FSW) giveslimited applicability

- bulky equipment

- Limited connection surface.

Wryfsweis, beginsel en kenmerke:

Wrywinglas is 'n soort druksweis waarin verwarming uitgaan deur wrywing wat veroorsaak word deur die draai van die gelaste produk.

As gevolg van die opkomende wrywingskragte by die raakpunte vind 'n baie vinnige verhitting en oorgang van die materiaal na 'n plastiese toestand plaas.

Wryksweis gaan dus deur 'n proses waarin meganiese energie wat aan een van die onderdele wat gesweis word, in hitte omgeskakel word.

Wrywinglas is 'n proses wat die meganiese energie van die beweging van een van die dele omskakel in hitte-energie. Rotasie is die algemeenste metode hiervoor. Net so kan een van die dele of 'n insetsel tussen hulle draai. Terselfdertyd druk die dele teen mekaar deur konstante of toenemende druk. In hierdie geval vind die verwarming direk plaas by die aansluiting van die onderdele.

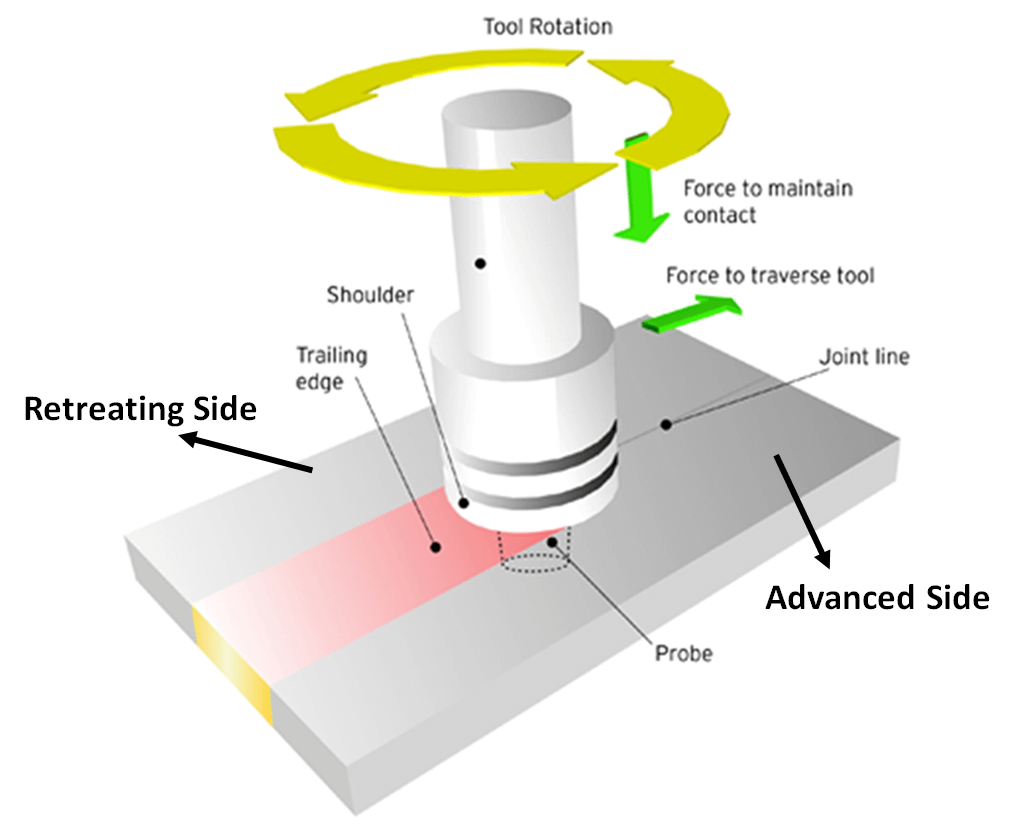

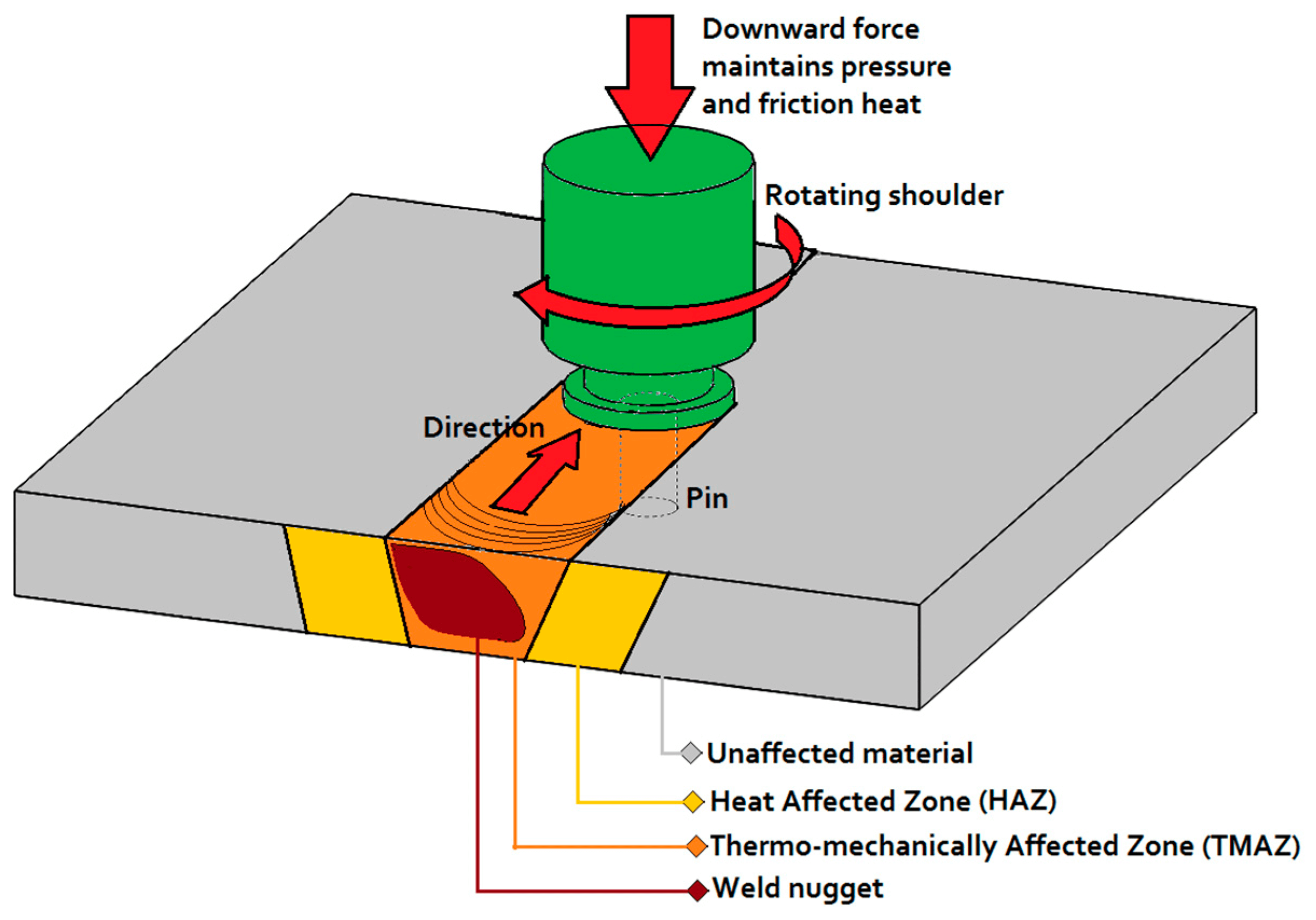

How does Friction Stir Welding (FSW) work?

Wrywingstrooisweis (FSW) process is not so simple. After the completion of the welding process, upsetting occurs and the rotation stops quickly.

In the welding zone at the joints of the parts, the following processes take place: with an increase in the rotation frequency of the workpieces and the effect of compressive pressure, the contact surfaces rub against each other.

Similarly, fatty and contact films present on parts in their original state are destroyed. After which the boundary friction comes by dry friction. Hence, individual micro protrusions begin to contact each other and deform.

Juvenile areas form, where the bonds of surface atoms do not saturate. Moreover, metal bonds immediately appear between them. In addition, they immediately destroy due to the relative movement of the surfaces.

Principles of using friction stir welding for joints

This process means that one does during its rotation. Moreover, it will create thermal energy, as a result of which the materials combines with each other.

But not only one of the parts can rotate, but also a special tool for friction stir welding in the form of an insert. In addition, it also contributes to a high-quality connection of parts.

Friction welding: technology features

Friction welding is a subtype of pressure welding. The technology involves heating the parts to be welded using friction. For this, one of them moves (rotates), while welding with the other.

Application area of Friction Stir Welding (FSW)

Friction Stir Welding (FSW)is most widely applicable in mechanical engineering, primarily in tool production. It is also common in the assembly of internals of nuclear reactors. Friction bonding of aluminum and magnesium alloy workpieces is popular in:

- electrical engineering

- electronics and

- aerospace

The technology is also common in transport engineering. The radial method is famous in the production of equipment for the mining and processing industries.

Afsluiting

More recently, Wrywingstrooisweis (FSW) has begun its journey in shipbuilding and food processing engineering.

Ons het so 'n proses soos wrywingsweis behandel. Soos u kan sien, verskil hierdie sweisproses van ander en hou dit baie voordele in. Dit is egter baie spesifiek en nie geskik vir alle take nie. Nietemin is die gebruik daarvan in baie gevalle geregverdig.

Die tegnologie toon doeltreffendheid en die neiging om tradisionele sweismetodes te vervang in gebiede soos:

- om gesoldeerde en geklinkte gewrigte te vervang;

- Kontak elektriese sweiswerk vervang;

- om produkte en ingewikkelde gereedskap te herstel;

- vir die sweis van werkstukke aan voorbereide oppervlaktes