What are the steps in the mold processing process?

2020-03-23What are the steps in the mold processing process?

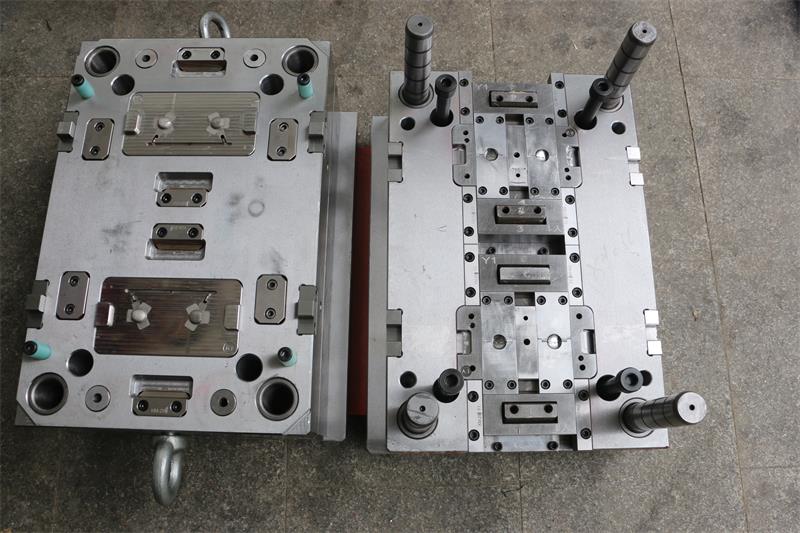

የ የሻጋታ ማቀነባበሪያ ሂደት is from cutting to processing and finishing. Established is a hardware and plastic mold manufacturer. I will share it with you and hope to help you.

Cutting material: front mold material, rear mold material, insert material, row material, inclined top material;

Open frame: front mold frame, rear mold frame;

Thickening: the front mold core is thick, the rear mold core is thick, and the parting line is thick;

Copper males: front male copper males, rear male copper males, and parting line milling copper males;

Line cutting: insert parting line, copper male, inclined top pillow;

Computer gong: fine gong parting line, fine gong mold core;

Spark discharge: rough front mold, copper male, male mold wire surface milling, rear mold bone position, pillow position;

Punching, pin eye, die thimble;

Row position, row position pressure pole;

Inclined top

Compound mold thimble, equipped with mold thimble;

Others: ① Tsui Tsui, die pits, waste nails (limit switch nails); ② flying molds; ③ water parts, braces, elastic yellow, and water;

Provincial mold, grinding and polishing, front mold, rear mold bone position;

Fine water structure, support rod screw hook, elastic yellow

Heat treatment, surface nitriding;

Repair printing.

Expertise in stamping dies

Design basis

Specification accuracy The accuracy of the specification between the two.

According to the actual requirements and functions of all the products of plastic products, it is clear which type of external quality and actual specifications belong to:

Plastic products with high appearance quality requirements and low specification accuracy requirements, such as small toys;

Versatile plastic products with strict specifications;

The appearance and specifications are strictly plastic products, such as digital cameras.

Is the die tilt effective?

The inclination of the ejection is related to the ejection and quality of the plastic product, which is related to the entire process of the injection.

There is sufficient inclination of the die;

ዝንባሌው በመፍጠር ላይ ካለው የፕላስቲክ ምርት መለያየት ወይም መለያየት ፊት ጋር መቀላቀል አለበት ፤ የመልክ እና የግድግዳ ውፍረት መመዘኛዎች ትክክለኝነት አደጋ ላይ የሚጥል መሆን አለመሆኑን;

የአንዳንድ የፕላስቲክ ምርቶች የመጭመቂያ ጥንካሬን አደጋ ላይ ይጥላልን?

የዲዛይን መርሃግብር ፍሰት

Analysis and digestion of plastic product drawings and solid lines (styles):

A. The geometrical appearance of the product; B. Specifications, dimensional tolerances and design scheme standards;

C, technical standards; D, plastic name, model E, surface regulations

Cavity Total and Cavity Sort:

A. The net weight of the product and the injection amount of the injection machine; B. The developed area of the product and the clamping force of the injection machine;

C. The size of the abrasive tool and the reasonable total area of the abrasive tool installed in the injection machine (or the space inside the support rod of the injection machine)

D. Product accuracy and color; E. Whether the product has a side shaft core and the solution;

F. Manufacturing large quantities of products; G. Economic benefits (manufacturing value of each mold)

After the total number of cavities is clear, the sorting of the cavities is carried out, that is, the layout of the cavity parts. The sorting of the cavities involves the specifications of the grinding tools, the design plan of the pouring system software, the balance of the pouring system software, and core pulling (rail slider) The design scheme of the organization, the design scheme of the inserts and cores, and the design scheme of the heat exchanger system software. This problem is related to the selection of the clinical diagnosis surface and the gate location. Therefore, the actual design scheme should be carried out throughout the process. Necessary adjustments to achieve a more extreme design solution.

ክሊኒካዊ ምርመራን ማብራራት

መልክን አይጎዳውም;

የሸቀጣ ሸቀጣ ሸቀጣ ሸቀጣ ሸቀጣ ሸቀጣ ሸቀጣ ሸቀጣ ሸቀጣ ሸቀጣ ሸቀጣ ሸቀጣ ሸቀጣ ሸቀጣ ሸቀጣ ሸቀጣ ሸቀጣ ሸቀጣ ሸቀጣ ሸቀጣ ሸቀጣ ሸቀጣ ሸቀጣ ሸቀጣ ሸቀጣ ሸቀጣ ሸቀጣ ሸቀጣ ሸቀጣ ሸቀጣ ሸቀጣ ሸቀጣ ሸቀጣ ሸቀጣ ሸቀጣ ሸቀጣ ሸቀጣ ሸቀጣ ሸቀጣ ሸቀጣ ሸቀጣ ሸቀጣ ሸቀጣ ሸቀጣ ሸቀጣ ሸቀጣ ሸቀጣ ሸቀጣ ሸቀጣ ሸቀጣ ሸቀጣ ሸቀጣ ሸቀጣ ሸቀጣ ሸቀጣ ሸቀጣ ሸቀጣ ሸቀጣ ሸቀጦች ላይ ትክክለኛነት ማረጋገጥ ጠቃሚ ነው ፣ እና ሻጋታ ማምረቻ እንዲሁም የጉድጓዱን ማምረት እና ማቀነባበር ማረጋገጥ ጠቃሚ ነው ፡፡

የስርዓት ሶፍትዌሮችን ፣ የፍሳሽ ማስወገጃ ስርዓትን እና የማቀዝቀዣ ስርዓትን ለማፍሰስ ጠቃሚ የንድፍ እቅዶች;

በሚወጣበት ጊዜ ምርቱ በሚንቀሳቀሰው ሻጋታ ጎን ላይ መትረፉን ማረጋገጥ ለዋጩ (መለያየት ፣ ማስወጣት) ጠቃሚ ነው;

የብረት ማስገቢያዎችን ስርጭት ያመቻቻል ፡፡

የስርዓት ሶፍትዌሮችን የማፍሰስ ንድፍ እቅድ

የማፍሰስ ቁጥጥር ስርዓት ዲዛይን ዋና ዋና የምርት መስመሮችን መምረጥ ፣ የመስቀለኛ ክፍል ገጽታ ማብራሪያ እና የመለያ መንገዶች ዝርዝር ፣ የበር አካባቢው ምርጫ ፣ የበር ዘዴ እና የበር መስቀለኛ ክፍል ማብራሪያን ያጠቃልላል ዝርዝር መግለጫዎች የዋሻው መውደቅ እንዲሁ ለበር መሣሪያው ዲዛይን እቅድ እና ለበሩ መሣሪያ በር በር መዋቅር ትኩረት መስጠት አለበት ፡፡

የመፍሰሻውን ስርዓት ሶፍትዌር በሚነድፉበት ጊዜ የመጀመሪያው እርምጃ የበሩን ቦታ መምረጥ ነው ፡፡ የበር አከባቢዎች ምርጫ ከምርቱ ለስላሳ አሠራር እና ከጠቅላላው የመርፌ ሂደት ጋር ይዛመዳል ፡፡ የበር አከባቢዎች ምርጫ የሚከተሉትን መመዘኛዎች መከተል አለባቸው-

① The gate should be selected on the clinical diagnosis surface as much as possible to facilitate the removal of the gate during mold manufacturing and application;

② The distance between the gate and each part of the cavity should be as consistent as possible, and the number of steps should be minimized;

③ The position of the gate should ensure that when the plastic is injected into the cavity, the cavity is wide and thin, and the thin-walled part is convenient for the satisfactory injection of the plastic;

④ The gate should be set at a thicker cross section of plastic parts;

⑤ Prevent plastic from impacting the cavity wall, core or insert when it flows down, so that plastic can be injected into various parts of the cavity as soon as possible, and prevent deformation of the core or insert;

⑥ Minimize the melting marks caused by the products, or the uncritical parts of the products caused by the melting marks;

The gate location and plastic injection orientation should be such that when the plastic is injected into the cavity, it can be injected symmetrically along the orientation of the parallel plane of the cavity, which is beneficial to the exhaust of gas in the cavity;

The gate should be set on the part that is easy to remove on the product, and the appearance of the product should not be endangered as much as possible.