ትክክለኛ የማሽን መለዋወጫ ክፍል | የ CNC ትክክለኛነት ማሽነሪ Essai

2020-05-22የተስተካከለ ትክክለኛ የማሽን መለዋወጫ ክፍል አገልግሎት

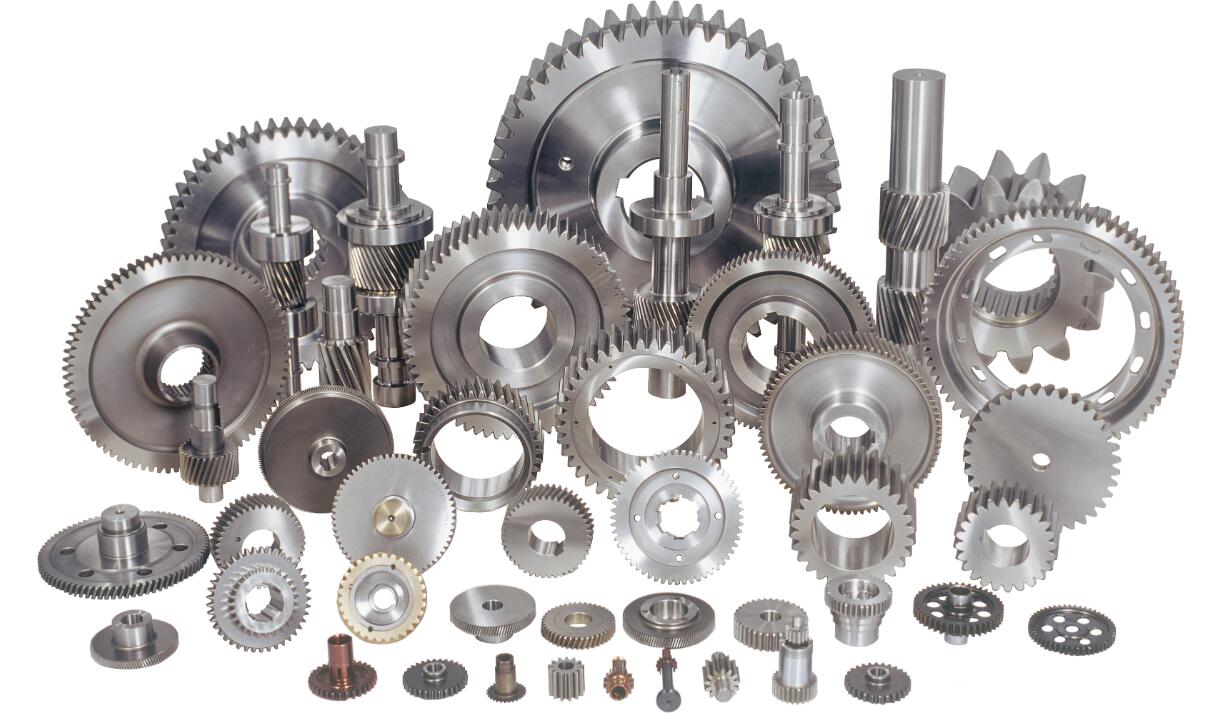

ትክክለኝነት ማሽነሪ እጅግ በጣም ውስብስብ የብረት ክፍሎችን ያመነጫል ፣ አብዛኛዎቹ ቀጭን የብረት ወረቀቶች ናቸው። ከትክክለታማ የብረት አካላት በተጨማሪ ብጁ ምርቶች ብዙውን ጊዜ ለተለዩ ዓላማዎች ይመረታሉ ፡፡ ሆኖም ትክክለኛነትን የብረት ክፍሎችን ለመሥራት እንደ ኬሚካል መቅረጽ ፣ የብረት ማተም ፣ እና RF መከላከያ የመሳሰሉት የተለያዩ ቴክኒኮች አሉ ፡፡

The chemical engraving process is mainly used to manufacture precision metal parts. The machining system offers great flexibility in the manufacture of precision metal parts with unusual configurations, as well as metals with tight tolerances within 0.0005 inches. In addition to chemical etchers, small holes and bars can be made that are not possible with most. The chemical engraving machine uses state-of-the-art CAD software with a resolution of ¼ million in the production process, which enables fast and inexpensive processes. The processing system is ideal for both prototype and production. large amounts of accuracy. Metal parts Mechanized chemical engraving products also play an important role in supporting NASA's research system.

Similarly, the manufacture of precision metal parts from 0.002 "to 135" thick usually uses the metal stamping process, also known as progressive stamping or long-lasting metal stamping. The technique is mainly used to process low-cost three-dimensional parts.

Shield processing r f allows the processing of precision metal parts such as HF shields. The machine helps to manufacture custom and standard RF shields. The machine is capable of producing product parts from a simple five-sided box to a complex multi-cavity protection with removable lids. In addition to the machining process, it facilitates the manufacture of flat, molded, coated, detachable lids with or without logos and part numbers. In addition, standard RF shields are available in 54 dimensions and are equipped with a prototype kit that allows the operator to design RF protection devices flexibly.

Advances in precision machinery have been a major boost for the aerospace industry, as aircraft need parts that are crafted to perfection. Precision machining has made it possible to manufacture improved hospital tools and thus also serve a social cause.

ጥቅሞች

Many companies that already hire manufacturers to perform precision machining processes, or even companies that already use these production methods on their own facilities, know some of the best-known advantages of precision machining. Including ሲኤንሲ መፍጨት and milling, these techniques have many advantages.

This includes eliminating human errors and increasing productivity due to the quality and fast production capacity of the devices. There are also other generally accepted advantages to these production methods, including the fact that they can be very profitable in the long run and can give companies that use them a clear competitive advantage.

However, there are many hidden benefits of precision machining for companies that some professionals may not take into account. Here are three lesser known benefits to consider when considering this method of production.

First, precision machining processes such as ሲኤንሲ መፍጨት and turning are very environmentally friendly production methods, that is, because much less material is wasted than with other more conventional production methods.

This is mainly because computers perform precise and accurate calculations before manufacturing and these calculations control the entire production process. This eliminates human error and ensures absolute consistency every time a part or component is produced.

As a result, much less material is wasted because these accurate measurements are performed and are performed increasingly without errors. This not only allows the company to waste money by spending part of its budget on producing items that in the end do not serve its purpose, but also avoids wasting valuable resources.

ሁለተኛው የተደበቀ ጠቀሜታ እንደ ሲኤንሲ መፍጨት በማኑፋክቸሪንግ ሂደት ውስጥ ብዙ ደህንነታቸውን ጠብቀው በመቆየት ሰራተኞችን ሊጠቅሙ ይችላሉ ፡ በተለምዶ በምርት ሂደት ውስጥ ከባድ ማሽነሪዎችን ማሠራቱ በጣም አደገኛ ሲሆን በየአመቱ ብዙ ጉዳቶችን እና ድንገተኛ አደጋዎችን ያስከትላል ፡፡

ሆኖም ግን ፣ በማሽኖች ቁጥጥር ፣ በኮምፒተር ቁጥጥር የሚደረግ ትክክለኛነት ማሽነሪ በመጣበት ጊዜ ችሎታ ያላቸው ሰራተኞች እና መሐንዲሶች እንደ መሳሪያዎች እንደሚያደርጉት በማሽነሪንግ አካላት እና ክፍሎች አደገኛ ገጽታዎች ውስጥ በአካል ሳይሳተፉ የሂደቱን ሂደት መከታተል አለባቸው ፣ ሁሉም ነገር ተለወጠ ፡፡ . ኮምፒተር ተቆጣጠረ.

ይህ የሠራተኛውን ኃይል በሥራ ላይ ለማቆየት እና ለከባድ የአካል ጉዳቶች እና አደጋዎች ተጋላጭነትን በከፍተኛ ሁኔታ ለመቀነስ ይረዳል ፡፡ ይህ ደግሞ የሞራል እና የሥራ እርካታን ሊጨምር ይችላል ፣ ይህም በእርግጥ በኩባንያው አሠራር እና በአጠቃላይ በኩባንያው ስኬት ላይ በጣም አዎንታዊ ውጤት አለው።

እንደ ወፍጮ እና ሲኤንሲ መፍጨት ያሉ ትክክለኛነት የማሽን ቴክኒኮች የመጨረሻ የተደበቀ ጠቀሜታ እጅግ በጣም የሚስማሙ በመሆናቸው እና ለብዙ ኢንዱስትሪዎች የተለያዩ ክፍሎችን እና ክፍሎችን ለማምረት ሊያገለግል ይችላል ፡፡ ይህ የሚገዙት መሣሪያ በቅርብ ጊዜ ውስጥ ጊዜ ያለፈባቸው ናቸው የሚል ስጋት ስለሌላቸው ይህ ለንግድ ድርጅቶች ጠቃሚ ነው ፡፡

Although there are different types of precision machining tools, after purchase they will be suitable for many different manufacturing purposes in the coming years. Therefore, these items are a very solid and reliable investment for any company that wants to manufacture their own parts and components on site.

These are just three of the hidden benefits of precision machining tools. From offering a very recursive solution for the manufacturing industry to offering adaptability and flexibility, there are many reasons why companies should consider investing in such devices.

If you prefer, there are many contract manufacturers who offer their services and use high quality precision machining tools in their production processes.

Conclusion

Over time, the devices used became more and more computers, which led to the የሲ.ሲ.ኤን. ማሽነሪ process. Software developers and engineers started developing software that could control certain aspects of the machine, such as shaft speed, shaft movement, and others.

Because these precision machining services allowed the operator to tilt multiple axes at the same time, contouring operations in two or three dimensions were possible. This evolution has allowed users to be more flexible when it comes to the capabilities of their equipment, production lines, assembly lines and the like.

In terms of maximizing uptime, these precision machining services have allowed operators to operate a range of products simultaneously. This reality minimizes losses and costs without compromising the quality of the production. It also reflects more profitable, productive, and reliable operations, which is particularly beneficial for companies that are still in the critical phase of their operations.

In terms of control and operation, the CNC machining system can be managed using two types of programming languages: conversation and camera production or computer-aided production programming languages. The first is the simplest system that uses a generalist language that instructs the system to work with certain preprogrammed cycles. The latter is a more complex process, but it allows the user to achieve more personalized results by feeding the part provided in a CAM system and determining the parameters for its machined parts.