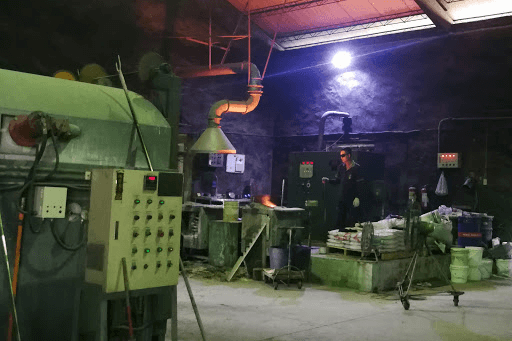

ዴዋክስንግ ተዋንያንን መዉሰድ-የ Sheል መበስበስን በተመለከተ ዕውቀት

2020-08-24የደዋክሲንግ ውሰድ አስፈላጊነት

የኢንቬስትሜንት ውሰድ ሂደት Dewaxing casting ትልቅ ጠቀሜታ አለው ፡፡ የሻጋታውን ጥራት እና ስብጥር ሊገልጽ ስለሚችል ትክክለኛ ዕውቀት ሊኖርዎት ይገባል ፡፡ የዲ-ሰም የመጣል ዘዴ ብዙ ገጽታዎች አሉ።

በዚህ ጽሑፍ ሂደት ውስጥ ስለ ዛጎሉ ማወዛወዝ እንነጋገራለን ፡፡ ስለዚህ ፣ ያለ ተጨማሪ መዘግየት ፣ እንጀምር!

የ “Dewaxing casting” መግቢያ

To ensure the quality of investment cast mould, it is imperative to pay close heed to the wax removing process. After all, it is among the most important step of the cost mould. Dewax can lead to a number of problems.

For instance, it can cause microcracks. After all, the de-waxed or the green shells are fragile and vulnerable before firing. To hold the components of the shells together, manufacturers either use fibers and polymers or colloidal networks.

In most cases, the manufacturers depend upon the autoclaving method for removing wax patterns. However, there are certain manufacturers that de-wax via the flash firing method. The choice greatly depends upon the manufacturer’s preferences and requirements.

በመጋገሪያ ምድጃ ውስጥ ካለው አየር ይልቅ የእንፋሎት መጠቀሙ ዋነኛው ጥቅም ውጤታማ እና ቀልጣፋ የኃይል ሽግግር ወደ ሰም በይነገጽ ንብርብር ማረጋገጥ ነው ፡፡ ከዚህም በላይ የራስ-ሰር ማድረጊያ ዘዴዎች የቀለጠውን ሰም እንደገና ለማደስ ይፈቅዳሉ ፡፡

በተጨማሪም ከብልጭቱ የማስነሻ ዘዴ ጋር ሲያወዳድሩ የብክለት ጋዝ ልቀትን ይቀንሳል ፡፡ የራስ-ሰር የማስወገጃ ሂደት ከተጠናቀቀ በኋላ ወደ ኋላ የቀረው ሰም በጣም ትንሽ ነው። ይህ በመተኮሱ ሂደት አመድ አነስተኛ ምርት ያስከትላል ፡፡

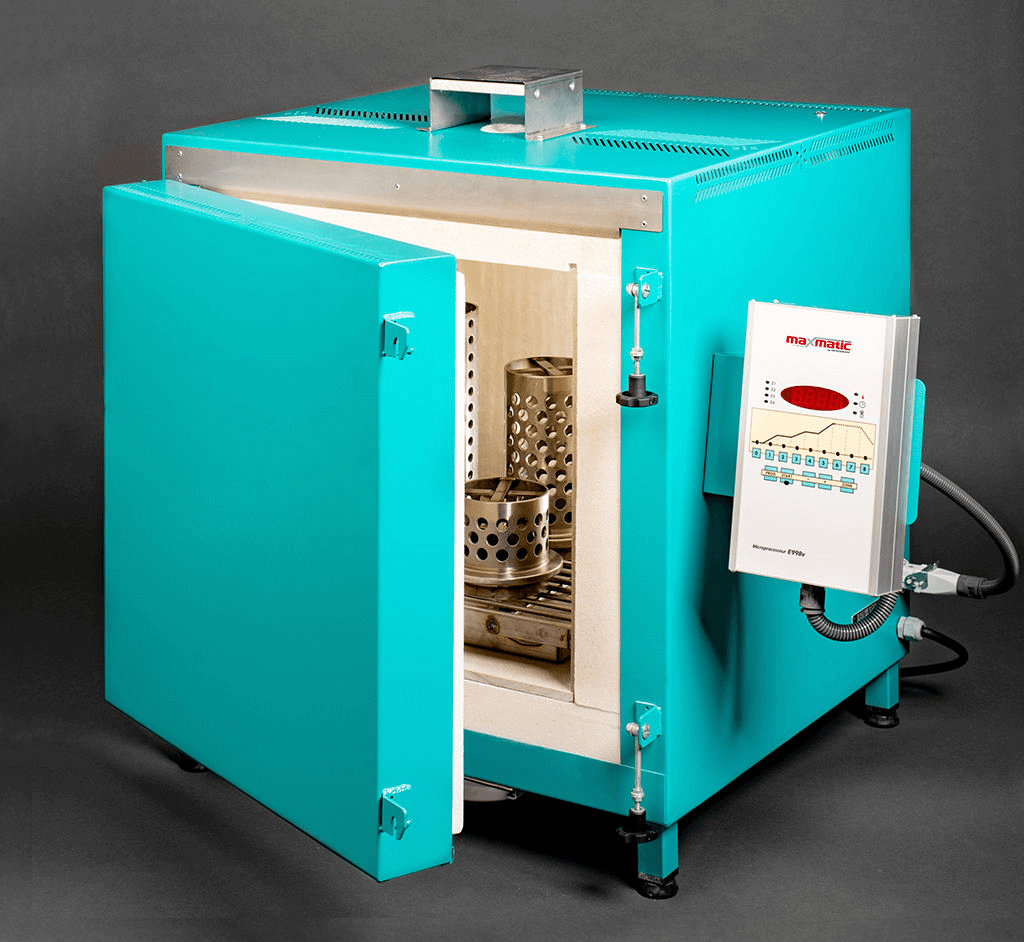

የራስ-ሰር የማስወገድ ዘዴ

ለፈጣን የሙቀት ምንጭ የራስ-አሰራሩ ሂደት በእንፋሎት ይጠቀማል ፡፡ እንፋሎት ከቅርፊቱ ወለል ጋር በደንብ ይተዋወቃል። የእንፋሎት የማያቋርጥ ማስተዋወቅ በ theል ውስጥ ባለው ጠንካራ ሰም ውስጥ ወደ ሁኔታው ለውጥ ይመራል ፡፡

ሰም መቅለጥ ይጀምራል እና በተመሳሳይ ጊዜ በ theል ውስጠኛው ወለል ላይ ከፍተኛ ጭንቀት አለ። ጭንቀቱ የፈሳሽ መጠን መስፋፋቱ እና የደረጃው ለውጥ ውጤት ነው።

ማሳሰቢያ: - በማስፋፋቱ ምክንያት የቅርፊቱ ውስጡን ግፊት በፍጥነት ለመልቀቅ በጣም አስፈላጊ ነው። የግፊት መለቀቅ አለመኖር ወደ ዛጎሉ መሰንጠቅ ያስከትላል ፡፡

የመልቀቂያ ዘዴ

የግፊት መለቀቅ ዘዴ ቀላል እና ውጤታማ ነው ፡፡ Happensሉ ወደ ዛጎሉ ውስጥ ዘልቆ የሚገባውን እንፋሎት ውስጡን ጠጣር ሰም ከቀለጠ በኋላ የቀለጠው ሰም ከዚያ ወደ ዋናው ሽፋን ይለፋል ፡፡ ወደ ዋናው ካፖርት ለመግባት ሰም ወደ ዛጎሉ ዘልቆ ይገባል ፡፡

The decrease in the shell stress is due to the penetration of the liquid wax into the prime coat. Likewise, the polymer present in the shell makes it robust and strong. It offers a better system for absorbing the pressure that is building up in the shell.

Prime Coat- Shell Properties

Manufacturers greatly emphasize the fact that relieving the right amount of pressure via the prime is important. However, it is important to understand that the pressure relieve should not compensate for the integrity of the prime coat nor should it have an adverse impact on the surface roughness.

To increase the shell's ability to withstand pressure, manufacturers something incorporate polymers into the prime slurry. The polymers also help absorb the wax expansion. Thus, making the shell sturdy and strong.

It is important to wet the prime coat using the liquid wax as this would ensure better shell permeability. There are several factors that influence surface wetting. For instance, the temperature, surface heterogeneity, roughness of the prime coat surface, wax liquid characteristics, and the rate of wetting.

Backup Coat- Shell Properties

In order to avoid all sorts of shell cracking, you need to pay extra attention to back up coats. After all, these coats need additional strength for the penetration of the shell cracking. The number of back up coats greatly depends upon the mechanical strength and the slurry system.

You can have as little as four backup coats or the number can go up to 12 or so. Do bear in mind that the shell thickness would lead to an increase in the heat capacity of the shell. Thicker the shell, higher its heat capacity.

Also, higher thickness requires additional steam energy to convert the solid wax within into liquid wax. Thus, you need to have a balance of the permeable shell system. Prevent the right amount of steam penetration along with good mechanical strength.

To further enhance the stability and the survivability rate, it is a good idea to add polymers to the shells.

Dewaxing Casting Properties

For the making of investment casting-pattern waxes, manufactures mainly use the microcrystalline waxes and the paraffin waxes as the base wax. They then add plasticizer, fillers, and resin. However, the decision of adding plasticizer, resin, and fillers depends upon the application type.

Each factor offers different benefits. Like, adding fillers to the wax would reduce shrinkage, it would enhance dimensional performance and result in better mechanical properties.

For the designing of wax good for autoclaving dewaxing casting, there are different parameters that hold importance. For instance, you would have to focus on the conductivity, heat capacity, melting point, viscosity, and thermal expansion.

Autoclave Dewaxing Suggestions

In most cases, the manufacturers suggest running auto-clave at least six bars in three seconds. Then allow the pressure to recover up to eight or nine bars. Do bear in mind that there should be a steady increase in the steam pressure along with the simple pressure.

Higher depressurization rate would have an adverse impact on the mold’s pressure pockets as well as the case of the condensed steam. This would then be leading to the cracking of the mold.

Also, to ensure the effectiveness and efficiency of the mold, we do recommend that you run a couple of dummy cycles. This would provide you with the idea of the outcome. It is important to incorporate seal inspection, regular maintenance, safety systems, and door operation in your daily inspection routine. However, this setting does differ from manufacturer to manufacturer.

In case you are looking for more information on dewaxing casting, reach out to us today. We will provide you with all the information that you require.