5 Factors for Choosing Professional Rapid Prototyping Method in 2020

2020-06-07Professional Rapid Prototyping: 5 Technique Selection Factors

A professional rapid prototyping manufacturer fully comprehends the fact that the failure or success of the prototype greatly depends upon the selection of prototyping techniques. When it comes to rapid prototyping, you have several ways to make up the product design.

You can either go with the simple cardboard mock-ups or the full functional machine assembled product. For modern-day products, prototyping has become imperative. This is crucial for new product development.

Rapid prototyping offers the facility to validate your design. It provides you with a rough model, thus allowing you to test its functionality. Moreover, you would get a précised idea of how your product would look, feel, and work in a real-time environment.

In this blog post, we are going to talk about part-base prototypes. In simpler words, we will tell you how you can use individual parts to create a system-level prototype.

Five Key Factors for Professional Rapid Prototyping Process

Since every product is unique, thus it will offer unique prototyping experience. The difference in every product, project, and product design elements, needs proper consideration.

A certain prototype that worked well for an XYZ product, might not generate the same effective results of your product. Therefore, you need to consider the five key factors below to make the right decision.

- Purpose

- Quality

- Cantidad

- Complejidad

- Costo

Let’s look deep into these factors and understand why they are important for choosing your next prototyping process.

Purpose

According to Ulrich and Eppinger, there are four reasons for creating a prototype within the engineering and development of product design as well as the product. These four reasons include communication, learning, milestones, and integration.

El propósito de la creación de prototipos varía según la etapa de desarrollo del producto. Generalmente, hay cuatro etapas de desarrollo de productos diferentes. Cada etapa del desarrollo de un producto tiene sus propias características, así como la funcionalidad necesaria para eliminar cualquier tipo de riesgo.

Esto revelaría el tipo de fidelidad del prototipo, es decir, de baja o alta fidelidad. El primer aspecto del propósito del prototipo del proyecto dependería de los ejercicios de mitigación de riesgos o de las pruebas planificadas.

Por ejemplo, comentarios sobre la interacción del cliente, tipos de pruebas, etc. En caso de que el prototipo vaya a pasar por pruebas rigurosas, es importante centrarse en el material. Después de todo, el material sería un factor decisivo en la elección de la técnica de creación rápida de prototipos.

Next, you need to focus on the functional aspect of the prototype. The selection and assembling would greatly depend upon the functional expectations of the prototype. Such as, do you want any moving part of your plan to perform functional testing.

It is highly less likely that your prototype becomes successful without any tweaks. Thus, you need to consider the changes and modification factors in your mind. It is important to consider how easy or difficult it would be to make changes to the prototype.

Doing this would also aid in deciding the right prototyping technique.

The Product Development States

Product Clarifying and Planning Task

This is the stage where you will have to provide early proof of concepts. Use industrial design prototypes, demonstrations or mock-ups.

Prototyping Technique

- 3D Printed Parts

- Carboard Mockups

- CNC Machined Foam Models

- Ensambles (SLS, SLA, FDM, etc.)

Diseño conceptual

En la etapa conceptual, generalmente necesita piezas escaladas. En algunos casos, necesitará ensamblajes del diseño, así como funcionalidad e interfaz de usuario limitadas.

Para obtener la forma y el tacto del producto, puede utilizar la pieza FDM. En caso de que desee más precisión, tendrá que pasar al siguiente nivel de impresión 3D. Elija el SLS o vaya con el SLA. También tiene la opción de piezas de chorro de polietileno.

En caso de que desee piezas de metal, entonces usar una máquina CNC en esta etapa sería algo excelente. Además, incluso puede considerar la fabricación de chapa. Sin embargo, la fabricación de láminas de metal funciona en situaciones limitadas.

Diseño de encarnación

In this phase, you would be exploring the full functionality of the prototype. A professional rapid prototyping manufacturer would be looking into its fit, form, and functions. Therefore, focusing on details is imperative. At this stage, the prototypes would be as similar to the final product as possible.

They would be containing several parts. Also, the testing phase expands here. You cannot limit your self to just a single testing technique. On the contrary, you would be needing different units for different testing purposes.

You would also be considering the final technique for manufacturing at this stage. The reason being, you would have to stimulate it eventually. Also, focus on high-resolution printing such as SLA and SLS for plastic parts.

Paying heed to vacuum casting is also important. Both the DMLS and SLM parts are perfect for simulating casting parts.

Detailed Design

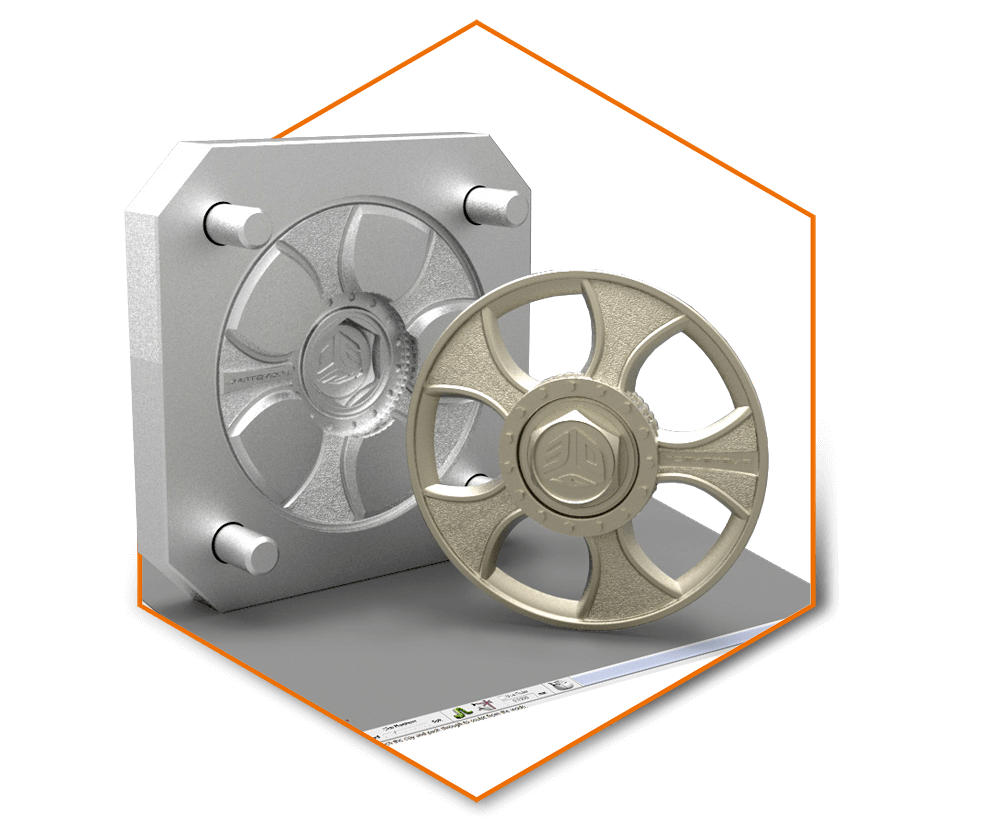

Any prototype developed in this phase would go for functional testing. Moreover, it would be used for pre-production pilot runs.

Professional rapid prototyping manufacture would use vacuum casting to prototype injection molding parts. In the case of machined plastic parts, they would be using the 3D printing technique.

Quality

As we mentioned above, the product accuracy and fidelity required would dictate the type of post-processing or process, you would need for the prototype. You need to focus on the quality of your prototype as well.

Although, high-fidelity prototypes are expensive, however, professional rapid prototyping manufacture consider them as a return on investment. For instance, you want to have a thread feature, we recommend using SLA in instead of the FDM. Unfortunately, SLA would cost you more.

Prototype Usage

The type of technology you use would also depend upon prototype usage. For example, if you plan to use the parts frequently, you should not consider self-tapping holes or 3D printed threaded holes. On the contrary, it would be used to opt for the metal inserts or machined inserts.

Material Selection

La calidad del prototipo depende en gran medida de la materia prima. Por lo tanto, debe prestar mucha atención al aspecto de selección de material de la fase de desarrollo. No recomendaríamos piezas fabricadas con aditivos, especialmente cuando existe un vínculo entre determinadas propiedades del material y los elementos funcionales del prototipo.

Consulte la tabla siguiente para ver la elección de material básico para diferentes técnicas de fabricación.

| Impresión 3d | CNC | Fundición al vacío |

|

TPU, ASA, ULTEM, ABS, PLA, nailon |

PEEK, policarbonato, nailon, ABS | Nylon HT, ABS

ABS, nailon nailon HT |

| Inconel, titanio, acero inoxidable, aluminio | Latón, titanio, acero inoxidable, aluminio | N / A |

Es importante tener en cuenta la tolerancia de las piezas de los prototipos, especialmente cuando un determinado prototipo compromete más de uno. La consideración de la tolerancia también ofrecerá facilidad de integración.

Cantidad

Otro factor importante que juega un papel vital a la hora de decidir el tipo de tecnología de creación de prototipos es la cantidad. Existen ciertas técnicas que serían rentables para cantidades más pequeñas y viceversa.

Consulte las siguientes reglas que se aplican.

Partes plásticas

| Procesos de prototipos | |||

| Partes plásticas | Cantidad | ||

| Bajo (1) | Medio (10's) | ||

| Talla | Grande | Impresión 3d | CNC Machining

Fundición al vacío |

| Pequeño | Impresión 3d | Mecanizado CNC (simple) Impresión 3D (complicado) |

|

Partes metalicas

| Procesos de prototipos | |||

| Partes Metálicas | Cantidad | ||

| Bajo (1) | Medio (10's) | ||

| Talla | Grande | El mecanizado CNC | El mecanizado CNC |

| Pequeño | 3D Printing

El mecanizado CNC |

Investment Casting

El mecanizado CNC |

|

Complejidad

La complejidad del producto ayudaría al proceso de selección del proceso de prototipo rápido. Los diferentes procesos ofrecen una complejidad diferente. Solo necesita concentrarse en el que se adapte a los requisitos de su prototipo.

Costo

Lastly, you need to focus on the resources available. After all, the prototype and the resources go hand-in-hand. You need to consider the man-hours, the money, and the time you would require to create a high-quality prototype.

Focusing on these aspects would also help you choose the right prototyping technique.

Take Away

As a professional rapid prototyping manufacturer, we keenly focus on the above 5 key factors. We fully understand that choosing the right prototyping technique would yield high-quality results. Therefore, we pay close attention to the purpose of your prototype.

In addition, we would pay close attention to the quality especially when it needs to be performed in a real-time environment. Our state-of-the-art technology helps us in handling prototyping of all sizes and shapes.

Tenemos la capacidad de manejar prototipos de bajo volumen y producción en masa sin tener ninguna diferencia en términos de calidad y perfección. Además, elegimos la técnica de creación de prototipos teniendo en cuenta el costo y la complejidad de su diseño.

Después de todo, todas las técnicas no pueden producir diseños complejos, sofisticados y de alta calidad. Para obtener más información sobre nosotros, haga clic aquí.