5 Factors for Choosing Professional Rapid Prototyping Method in 2020

2020-06-07Professional Rapid Prototyping: 5 Technique Selection Factors

A professional rapid prototyping manufacturer fully comprehends the fact that the failure or success of the prototype greatly depends upon the selection of prototyping techniques. When it comes to rapid prototyping, you have several ways to make up the product design.

You can either go with the simple cardboard mock-ups or the full functional machine assembled product. For modern-day products, prototyping has become imperative. This is crucial for new product development.

Rapid prototyping offers the facility to validate your design. It provides you with a rough model, thus allowing you to test its functionality. Moreover, you would get a précised idea of how your product would look, feel, and work in a real-time environment.

In this blog post, we are going to talk about part-base prototypes. In simpler words, we will tell you how you can use individual parts to create a system-level prototype.

Five Key Factors for Professional Rapid Prototyping Process

Since every product is unique, thus it will offer unique prototyping experience. The difference in every product, project, and product design elements, needs proper consideration.

A certain prototype that worked well for an XYZ product, might not generate the same effective results of your product. Therefore, you need to consider the five key factors below to make the right decision.

- Purpose

- Kualiti

- Quantity

- Complexity

- Cost

Let’s look deep into these factors and understand why they are important for choosing your next prototyping process.

Purpose

According to Ulrich and Eppinger, there are four reasons for creating a prototype within the engineering and development of product design as well as the product. These four reasons include communication, learning, milestones, and integration.

The purpose of prototyping varies depending on the development stage of the product. Generally, there are four different product development stages. Every stage of product development has its own features as well as the functionality required to eliminate any sort of risk.

This would give away the fidelity type of the prototype i.e. low-fidelity or high-fidelity. The first aspect of the project prototype purpose would depend upon either the risk mitigation exercises or the planned tests.

For instance, customer interaction feedback, or test types, etc. In case, the prototype is going to go through rigorous testing, then it is important to focus on the material. After all, the material would be a deciding factor in choosing the rapid prototyping technique.

Seterusnya, anda perlu fokus pada aspek fungsi prototaip. Pemilihan dan pemasangan akan sangat bergantung pada harapan fungsi prototaip. Seperti, adakah anda mahu mana-mana bahagian bergerak dari rancangan anda melakukan ujian berfungsi.

Kemungkinan besar prototaip anda berjaya tanpa perubahan. Oleh itu, anda perlu mempertimbangkan perubahan dan faktor pengubahsuaian dalam fikiran anda. Penting untuk mempertimbangkan betapa mudah atau sukarnya membuat perubahan pada prototaip.

Melakukan ini juga akan membantu dalam menentukan teknik prototaip yang betul.

Keadaan Pembangunan Produk

Tugas Penjelasan dan Perancangan Produk

Ini adalah tahap di mana anda perlu memberikan bukti konsep awal. Gunakan prototaip, demonstrasi atau mock-up reka bentuk industri.

Teknik Prototaip

- Bahagian Bercetak 3D

- Mockup Carboard

- Model Buih Mesin CNC

- Majlis (SLS, SLA, FDM, dll)

Rekabentuk konsep

Pada peringkat konseptual, anda biasanya memerlukan bahagian yang berskala. Dalam beberapa kes, anda memerlukan susunan reka bentuk serta fungsi dan antara muka pengguna yang terhad.

Untuk mendapatkan bentuk dan rasa produk, anda boleh menggunakan bahagian FDM. Sekiranya anda mahukan ketepatan yang lebih banyak, anda perlu beralih ke tahap pencetakan 3D seterusnya. Pilih SLS, atau ikut SLA. Anda juga mempunyai pilihan bahagian jet poli.

Sekiranya anda mahukan bahagian logam, maka menggunakan mesin CNC pada tahap ini adalah perkara yang baik untuk dilakukan. Anda juga boleh mempertimbangkan pembuatan logam lembaran. Walau bagaimanapun, fabrikasi logam lembaran berfungsi dalam keadaan terhad.

Reka Bentuk Perwujudan

In this phase, you would be exploring the full functionality of the prototype. A professional rapid prototyping manufacturer would be looking into its fit, form, and functions. Therefore, focusing on details is imperative. At this stage, the prototypes would be as similar to the final product as possible.

They would be containing several parts. Also, the testing phase expands here. You cannot limit your self to just a single testing technique. On the contrary, you would be needing different units for different testing purposes.

You would also be considering the final technique for manufacturing at this stage. The reason being, you would have to stimulate it eventually. Also, focus on high-resolution printing such as SLA and SLS for plastic parts.

Paying heed to vacuum casting is also important. Both the DMLS and SLM parts are perfect for simulating casting parts.

Detailed Design

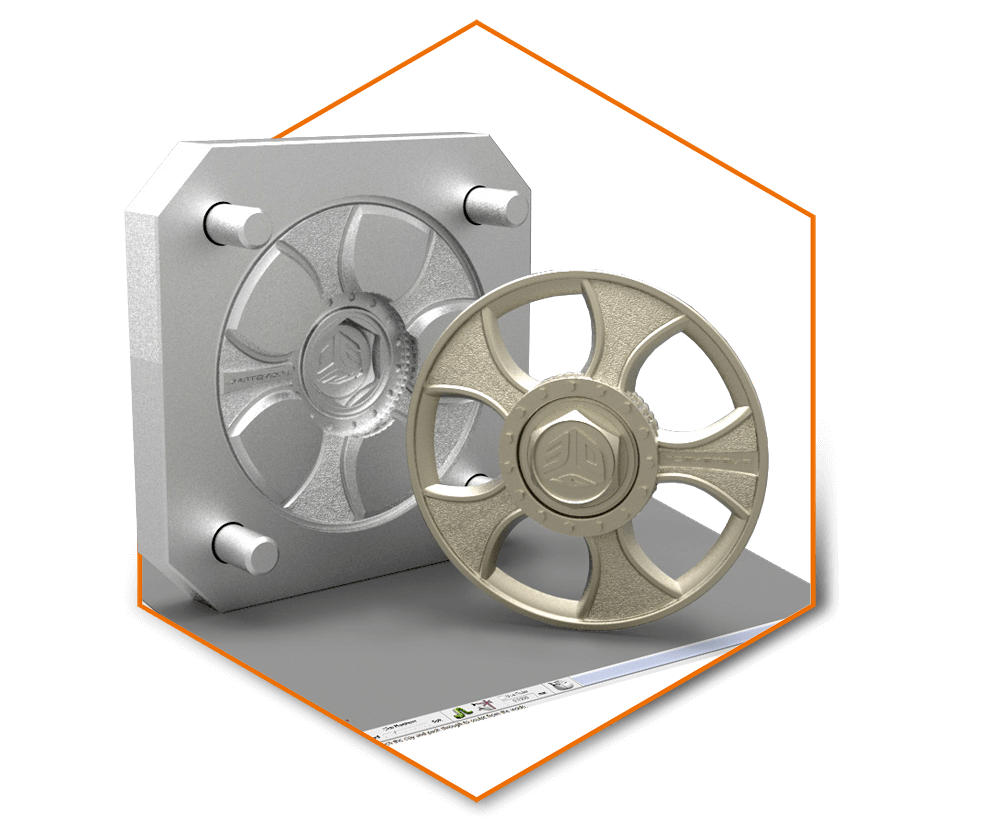

Any prototype developed in this phase would go for functional testing. Moreover, it would be used for pre-production pilot runs.

Professional rapid prototyping manufacture would use vacuum casting to prototype injection molding parts. In the case of machined plastic parts, they would be using the 3D printing technique.

Kualiti

As we mentioned above, the product accuracy and fidelity required would dictate the type of post-processing or process, you would need for the prototype. You need to focus on the quality of your prototype as well.

Although, high-fidelity prototypes are expensive, however, professional rapid prototyping manufacture consider them as a return on investment. For instance, you want to have a thread feature, we recommend using SLA in instead of the FDM. Unfortunately, SLA would cost you more.

Prototype Usage

The type of technology you use would also depend upon prototype usage. For example, if you plan to use the parts frequently, you should not consider self-tapping holes or 3D printed threaded holes. On the contrary, it would be used to opt for the metal inserts or machined inserts.

Material Selection

The quality of the prototype greatly depends upon the raw material. So, you need to pay close heed to the material selection aspect of the development phase. We would not recommend additive manufactured parts, especially when there is a link between the certain material properties and the functional elements of the prototype.

See the table below for the basic material choice for different manufacturing techniques.

| 3D printing | CNC | Vacuum casting |

|

TPU, ASA, ULTEM, ABS, PLA, Nylon |

PEEK, Polycarbonate, Nylon, ABS | Nylon HT, ABS

ABS, Nylon Nylon HT |

| Inconel, Titanium, Stainless Steel, Aluminum | Brass, Titanium, Stainless Steel, Aluminum | N/A |

It is important to consider the tolerance of prototypes parts especially when a certain prototype compromise of more than one. Tolerance consideration will also offer ease of integration.

Quantity

Another important factor that plays a vital role in deciding the type of prototyping technology is quantity. There are certain techniques that would be cost-effective for smaller quantities and vice versa.

See the following rules that apply.

Plastic Parts

| Prototype processes | |||

| Plastic parts | Quantity | ||

| Low (1's) | Medium (10's) | ||

| Size | Large | 3D printing | CNC Machining

Vacuum Casting |

| Small | 3D printing | CNC machining (simple) 3D printing (complicated) |

|

Metallic parts

| Prototype processes | |||

| Metallic Parts | Quantity | ||

| Low (1's) | Medium (10's) | ||

| Size | Large | pemesinan CNC | pemesinan CNC |

| Small | 3D Printing

pemesinan CNC |

Investment Casting

pemesinan CNC |

|

Complexity

The complexity of the product would help aid the rapid prototype process selection process. Different processes offer different complexity. You just need to focus on the one that would suit your prototype requirement.

Cost

Akhir sekali, anda perlu memberi tumpuan kepada sumber yang ada. Lagipun, prototaip dan sumbernya berganding bahu. Anda perlu mempertimbangkan jam kerja, wang, dan masa yang anda perlukan untuk membuat prototaip berkualiti tinggi.

Memfokuskan pada aspek-aspek ini juga akan membantu anda memilih teknik prototaip yang tepat.

Bawa pulang

Sebagai pengeluar prototaip pantas profesional, kami sangat fokus pada 5 faktor utama di atas. Kami memahami sepenuhnya bahawa memilih teknik prototaip yang tepat akan menghasilkan hasil yang berkualiti tinggi. Oleh itu, kami memperhatikan tujuan prototaip anda.

Selain itu, kami akan memperhatikan kualitas terutama ketika perlu dilakukan dalam lingkungan waktu nyata. Teknologi canggih kami membantu kami dalam menangani prototaip dari semua saiz dan bentuk.

Kami mempunyai kemampuan untuk menangani prototaip volume rendah dan juga pengeluaran besar-besaran tanpa perbezaan dari segi kualiti dan kesempurnaan. Lebih-lebih lagi kita memilih teknik prototaip sambil mengingat kos dan kerumitan reka bentuk anda.

Bagaimanapun, setiap teknik tidak dapat menghasilkan reka bentuk berkualiti tinggi, canggih, dan kompleks. Untuk mengetahui lebih lanjut mengenai kami, klik di sini.