Prototipe Cepat CNC

2020-05-25Prototipe Cepat CNC

Prototipe cepat idiom biasanya membingungkan banyak orang dengan manufaktur aditif atau pencetakan 3D. Namun, seperti namanya, Rapid Prototype hanyalah metode fabrikasi suku cadang dengan cara yang hemat biaya dan cepat. Prototipe adalah model yang digunakan untuk memverifikasi, menilai, dan menguji desain baru sebelum dapat dilanjutkan ke tahap selanjutnya dari tahap perluasan produk. Prototipe cepat tidak hanya terjangkau tetapi juga tersedia secara luas sebagai hasil dari kemajuan terbaru dalam teknologi pencetakan 3D. Namun, ada berbagai jenis teknik prototipe cepat yang, dalam beberapa kasus, telah terbukti lebih menguntungkan dibandingkan pencetakan 3D.

For example, Prototipe cepat CNC machining produces better-finished products in addition to being the most time and cost-saving technique. These benefits are the ultimate objective of any modern product development process. Remember, the choice for the most appropriate process approach depends on which type of prototype you need. If, for instance, if you are looking forward to testing your design ideas in your studio or creating an identical prototype for engineers to access your products aesthetic characteristics. Moreover, it makes possible to scale and size of your identical prototypes, and then the CNC rapid prototype has manners of printing available.

What is CNC rapid prototype, and how does it operate?

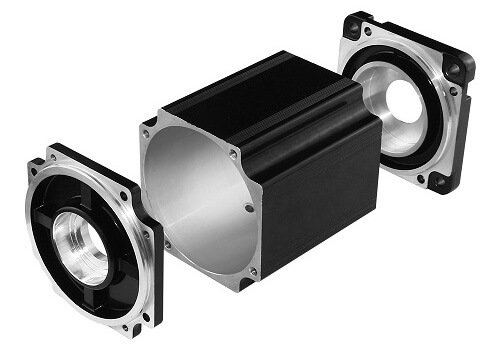

CNC is an abbreviation of the word Computer Numeric Control. It involves a set of different machines and a computer used to direct all interactions between the work pieces and the machining tools. Machining is a mechanical process that involves transforming a large amount of raw material into finished products—for instance, converting a large block into a final product through an appropriate content removing process. Such machines are computer-controlled and interact with work piece via a series of various codes known as M-codes or G-codes. These codes are generated using a commercially open software known as Computer-Aided Manufacturing software.

What are the benefits of CNC rapid prototype production?

It is true to say that CNC machines have greatly revolutionized most of the manufacturing industries in the 21st century. Some of the advantages of CNC machines include the following.

1. Matchless precision.

With CNC rapid prototype production capacity, all of your products' accuracy is fully guaranteed within a thousand divisions of an inch. The 3-axis machine is the main form of the CNC machine, which has its axis moving alongside the x, y, and z-axis when cutting various parts. The modern and advanced 5-axis machines have the capacity to spinning on both sides of the device, thus enhancing efficiency. The CNC's ability to create complex parts and with exceptionally tight tolerance to make accurate prototype and parts, thus making it suitable for both low and high volume productions.

2. It takes 24 hours production possible.

Unlike human workers, Prototipe cepat CNC production can work around the clock without taking breaks in-between and maintaining the highest accuracy and consistent quality. Such production makes it possible for the factory ability to produce in bulk, thus meeting the existing demand on its products within a shorter period and thus increasing its sales.

3. It makes it possible for scalability and mass production.

Mesin prototipe cepat adalah pilihan ideal untuk produksi massal suku cadang yang identik. Setelah data dimasukkan ke perangkat, perangkat dapat berjalan selama 24 jam melakukan operasi yang sama dan tanpa instruksi lebih lanjut. Misalnya, menggunakan mesin CNC yang menggunakan aluminium mesin CNC sebagai bahan baku produksi memudahkan desain Anda. Anda dapat menyesuaikan ukuran model prototipe Anda dengan faktor yang relevan tanpa harus membuat banyak perhitungan yang melelahkan. Semua angka yang Anda masukkan ke komputer Anda secara otomatis diproses ke hasil yang Anda inginkan dalam satu detik.

4. Peningkatan kapasitas produksi

With the usage of multi-axis CNC machines, the production of unattainable and complex geometries has been simplified. For instance, before the introduction of CNC rapid prototype machines, the creation of complicated parts and prototypes would have been to undergo processing for multiple times since the traditional machining techniques were susceptible to many faults. Besides conventional production methods, a lot of material wastage before the introduction of CNC machines. Still, now these challenges have been tacked, thus making production more cost-effective.

Consistency in production

As discussed above, CNC rapid prototype machines can handle exceptionally higher accuracy. This is because once you update the machines data according to your design want, no more data inputs is be required. Such production makes it possible to produce identical parts without any difference correctly, and this was almost impossible to achieve when using traditional techniques.

Better safety in the workplace

Remember, any factory has the mandate to keep the safety and health of its employer as a priority. Unlike traditional production methods, CNC rapid prototype machines have a very low probability of accidents happening. All CNC fast prototype machines come with numerous safeguards to ensure maximum protection and secure working environment for your workers.

Multipurpose production

Salah satu keuntungan menggunakan mesin CNC adalah Anda tidak terbatas pada jenis produksi tertentu. Anda memiliki kemungkinan hasil yang tak terbatas karena inovasi canggih dan fitur seni yang hadir dengan mesin CNC. Misalnya, prototipe cepat CNC dapat melakukan operasi yang membantu Anda menghasilkan barang yang identik dengan mudah dan akurat. Layanan pemesinan Prototipe CNC meliputi;

Clear Optical Prototyping ServicesProduksi prototipe kerjaIndustri, layanan prototipe otomotif

Jasa pemesinan aluminium

Prototipe cepat CNCproduksi telah membawa begitu banyak revolusi industri secara global. Misalnya, telah memungkinkan terciptanya produk berkualitas luar biasa karena kemampuannya yang canggih. Dibandingkan dengan proses produksi tradisional, teknologi prototipe cepat CNC telah memungkinkan pabrikan untuk menghasilkan geometri canggih dalam waktu sesingkat mungkin, biaya produksi lebih rendah, dan pengulangan yang jauh lebih baik. Biaya produksi massal adalah salah satu transformasi signifikan yang dimungkinkan oleh mesin CNC di dunia industri modern. Dengan meningkatnya permintaan untuk prototipe dalam produksi kontemporer, mesin prototipe cepat CNC telah terbukti menjadi pilihan terbaik untuk pabrik yang melakukan operasi semacam itu. Produksi semacam itu dapat dicapai karena prototipe dapat dibuat menggunakan bahan dan proses yang identik.