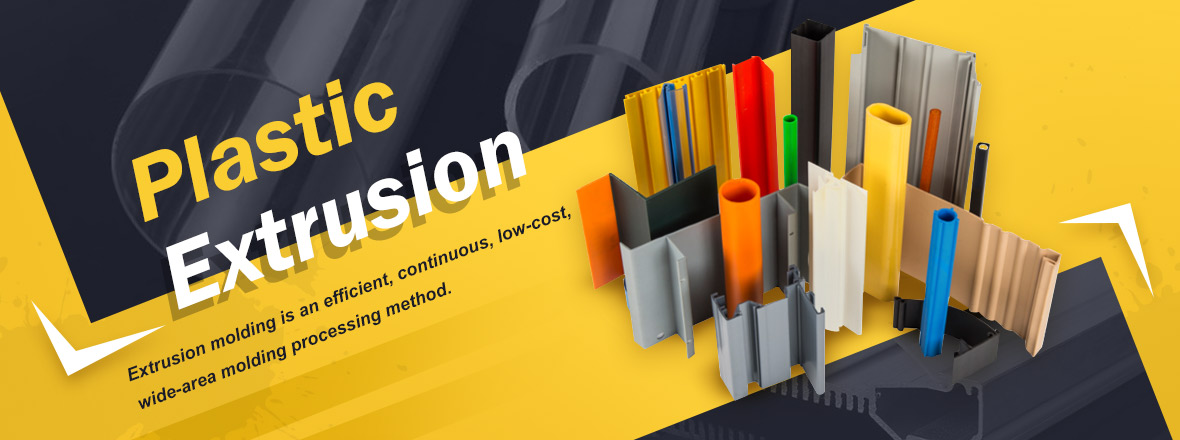

Plastic Extrusion

플라스틱 압출

Plastic Extrusion molding is an efficient, continuous, low-cost, wide-area molding processing method. It is an earlier technology in polymer material processing. After more than 100 years of development, extrusion molding is a field of polymer processing. The molding processing method with the most varieties, the most changes, high productivity, strong adaptability, wide use, and the largest proportion of output.

Extrusion is one of the most important forms of plastic material processing. The main materials are polyethylene (PE), polypropylene, acetal, acrylic, nylon (polyamide), polystyrene, polyvinyl chloride (PVC), Acrylonitrile butadiene styrene (ABS), polycarbonate, etc. It is suitable for most plastic materials except for some thermosetting plastics, about 50% of thermoplastic products are completed by extrusion molding. At the same time, also It is widely used in the molding of chemical fibers and thermoplastic elastomers and rubber products. Extrusion molding methods can produce various types of continuous products. Such as pipes, rods, sheet materials, profiles, wire and cable coatings, and monofilaments. It can be used for mixing, plasticizing, granulating, coloring and blending modification of polymer materials.

Essai uses a variety of plastic compounds to produce the highest quality plastic extruded products at competitive prices. We have more than ten years of experience and innovative technology in the plastic extrusion industry, which can ensure the provision of high-quality, cost-effective plastic extrusion parts so that your project can be successful. There are some common problems in the production of plastic profiles. Problems, deformation of the profile, bending of the profile, etc. So, how can we avoid these common problems in the profile during the production process?

Plastic profile modification

The existence of internal stress in plastic profiles not only causes bending deformation or cracking of the profiles in use but also affects mechanical properties and apparent quality. Causes of internal stress in plastic profiles:

1. The profile undergoes extrusion and stretching during the molding process. There is unrelaxed high elastic deformation in the orientation of the macromolecules. It is mainly concentrated on the surface layer so that there is large orientation stress in these places, and the orientation is uneven, leading to internal Non-uniform stress.

2. In the cooling stage of the profile, when the temperature is higher than the glass transition temperature, the plastic is a viscoelastic fluid with stress relaxation. When the temperature is lower than the glass transition temperature, the plastic becomes solid, and the curing time and chain. It is difficult to fully adapt between the relaxation speeds of the sections, and the profile after molding will always freeze the internal stress more or less.

3. 중공 프로파일의 벽 두께가 고르지 않습니다. 고르지 않은 냉각, 두꺼운 벽에서 느린 냉각, 얇은 벽에서 빠른 냉각, 냉각 속도에 차이를 형성하고 내부 응력을 유발하기 쉽습니다. 해결책 : 프로파일의 벽 두께는 가능한 한 동일하고 균일합니다. 다른 벽 두께가 필요한 경우. 섹션의 갑작스러운 변경을 피하기 위해 연결이 점차적으로 전환되어야합니다. 두꺼운 벽의 냉각은 세팅 몰드에서 적절하게 강화되어야합니다.

플라스틱 프로파일 굽힘

1. 전체 생산 라인은 중심선에서 조정되어야합니다. 프로파일이 건식 몰드를 물 탱크로 통과하고 마지막으로 냉각 될 때 중심선에 있지 않은 경우. 프로파일이 인위적으로 구부러 지거나 왜곡됩니다. 따라서 금형을 교체 할 때마다 압착해야합니다. 기계 밖으로, 헤드, 사이징 다이, 트랙터의 동심도 및 수평도의 정확한 수정.

2. 기계 헤드의 다이의 고르지 않은 배출, 불일치 속도는 굽힘을 유발하는 주요 요인 중 하나입니다. 기계 헤드의 흐름이 고르지 않은 경우. 차단 및 삽입을 통해 주변 재료를 균일하게 조정할 수 있습니다. 기계 헤드 측면의 온도 차이가 큰 경우. 다이 주변의 온도는 일정하게 조정되어야합니다.

다양한 유형의 플라스틱 압출 (스퀴즈) 제품 생산을 전문으로합니다. 고객 요구 사항에 따라 다양한 금형 개발, 친환경 및 특수 성능 제품 생산, 수입 원료 및 보조 재료, 과학 공식 및 첨단 기술을 사용하여 제품에 대한 신뢰할 수있는 품질 보증을 제공합니다. 우리는 강력한 기술력과 강력한 생산성, 안정적인 제품 품질을 보유하고 있으며 국내외로 수출됩니다.

1. we fabricated the tool by yourself so that it can reduce the tool cost.

2. Accept your MOQ at inital development.

3. High technology in plastic extrusion.

4. Good sevice from begining to ending and aftersales.

5. Good quality by virgin material and strict quality control.

6. The wear-resistant material can be customized by drawing or sample mold opening

Including PVC profiles, PP, PE, TPE profiles, ABS profiles, PMMA lampshade profiles, acrylic lens extrusions, LED PC profiles, two-color extrusion profiles, various slide rails, circuit guide rails and other engineering plastics, such as pvc / upvc / hdpe / pp / abs.

지금 비즈니스를 시작해 주셔서 감사합니다!

연락처