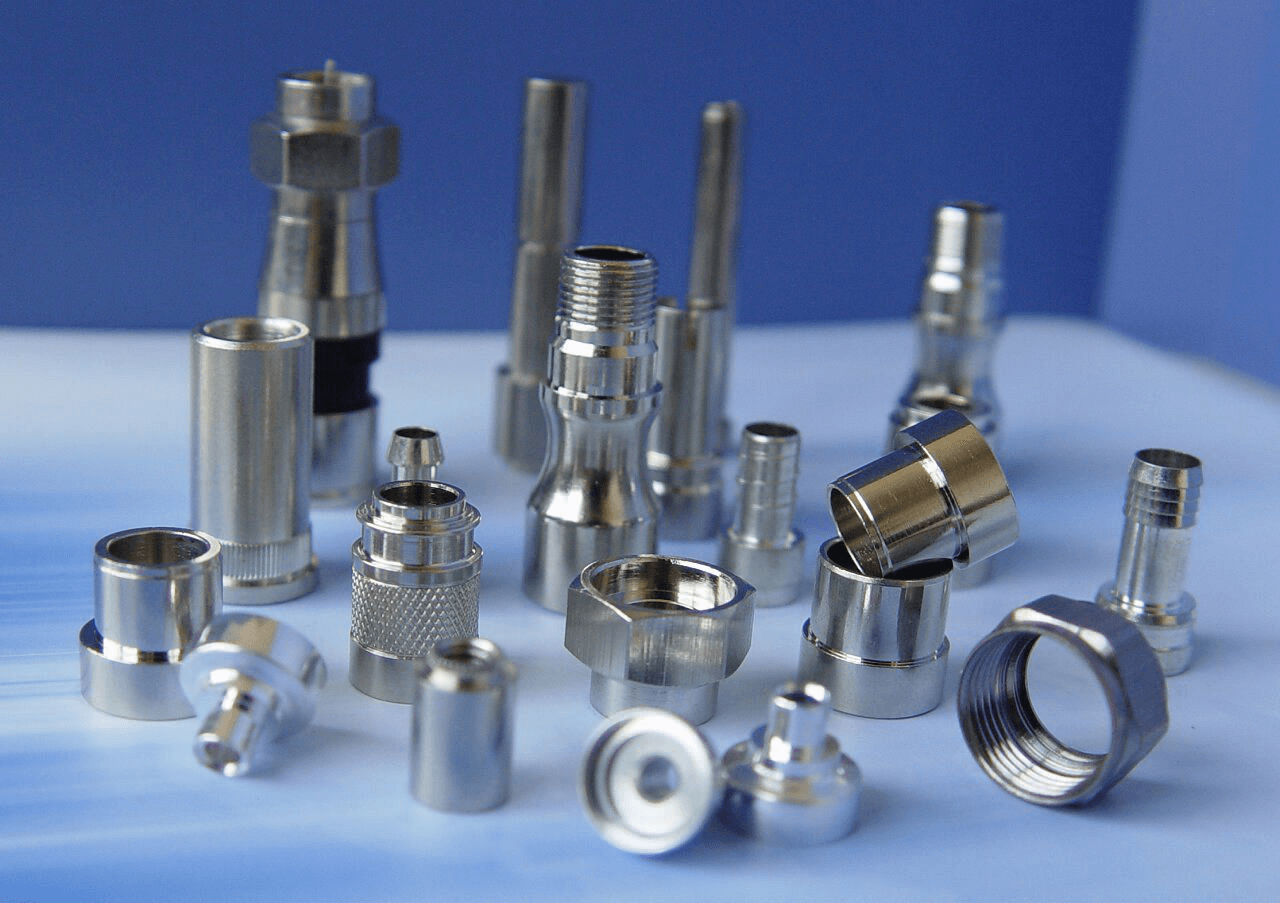

Beste Cnc Rapid Prototype & Cnc Metal Parts Tips die u graag zult lezen in 2020

2020-07-24Wat zijn CNC Rapid Prototype & CNC-metalen onderdelen?

CNC Rapid prototype & CNC-metalen onderdelen zijn in feite de methode om de werkende prototypes te ontwerpen en te genereren met behulp van 3D-modellen. De rapid prototyping maakt doorgaans gebruik van 2 soorten technologieën, zoals:

- CNC-bewerkingscentrum

- 3d printen.

Furthermore, with the help of these rapid prototypes, engineers can test several types of idea and theories. Moreover, these rapid prototypes testing are very simple and more inexpensive.

Daarom kunt u met behulp van CNC-snelle prototyping gemakkelijk echte en fysieke producten maken voor kleine thuisindustrieën tot grote productie-industrieën. Bovendien kunt u de werking en tooling controleren met behulp van prototypes voordat u van een eenvoudig product een complex maakt.

Welk soort materiaal wordt gebruikt in CNC Rapid prototype en CNC-metalen onderdelen ?

CNC Rapid Prototype & CNC Metal Parts hebben over het algemeen de mogelijkheid om de vormen en gecompliceerde ontwerpen van de volgende materialen te fabriceren. En deze materialen zijn:

- aluminium

- roestvrij staal

- Hout enz.

Bovendien, als u uw eigen project wilt starten, hoeft u alleen maar een online service te bestellen. Daarom hoeft u niet te investeren in grote CNC-machines.

What is the procedure to order for CNC Rapid prototype & CNC metal parts?

The online services of CNC machines simply work when you send an online order of your target products. And there are many different kinds of formats which are supportive and helpful.

These online service providers will collect the designs that you order and transform it in the prototypes of your design. These service providers have the responsibility to provide you perfect CNC Rapid prototype en CNC-metalen onderdelen. And these prototypes are very easy to apply and they are also very affordable and profitable for beginners.

Hence, you can easily receive the products of great quality on which you can trust.

From where you can order for CNC Rapid prototype & CNC metal parts?

As all of us know that CNC services which are online providing their services perfectly. Hence, you have no need to catch the local suppliers in order to develop the prototypes of your final products.

There is also possibility of occurring the faults as they may be not well skilled. And hence you have to suffer a lot as you are also a beginner. But online CNC Rapid prototype & CNC-metalen onderdelenservices also offer you a lot of options when we talk about budget.

So, you can easily select the packages of your requirements which also satisfy your budget. We all know that these service companies will provide their best assistance for your ordered products. Because there is an environment of competition among all online services.

Hence, there is no chance to make even a single mistake. And they are cost-effective also that you can easily save considerable amount even after handling and shipping costs. Furthermore, it is very comfortable and easy to work with these online prototype services because the files of designs are actually systematized.

But there is a single drawback of these CNC Rapid prototype en CNC-metalen onderdelen services and that is its time of shipping. When they use standard shipping, it generally takes 7 to 14 days altogether. And after this time period they will obviously deliver your order at your door steps.

But you are free to order your final designs of prototypes to any best provider which suits you the best in two ways, like:

- delivery time

- cost

Hoe werkt CNC Rapid prototype en CNC-metalen onderdelen services do rapid prototyping for bulk production?

Although all CNC machines have ability to fabricate and create complicated designs from a file of designs. So, there is basically not any type of limitations to fabricate or create a complex design of your needs. These CNC machines actually have the ability to handle any complexity.

Furthermore, these modern CNC Rapid prototype & CNC-metalen onderdelenmachines have the ability to produce one-off items with great accuracy and perfection. But CNC machines are basically designed for rapid prototyping of bulk production.

And for best prototyping you can make use of some other advanced technologies. Hence, 3D printing technology will be the best to create molds for the purpose of mass production. There is a demand of CNC technology in order to generate custom tooling for bulk production.

By using CNC technology, you can achieve your desired production molds with unbelievable precision and certainty. Furthermore, your ordered prototypes of final designs will have the high quality as well as perfect accuracy.

How in some cases CNC Rapid prototype en CNC-metalen onderdelen not perfectly suit to several prototype projects?

when we talk about an ideal project, then there is a possibility that even within a single cycle of CNC to fabricate all prototype. CNC metal parts basically allow creating all prototype in just one cycle. But engineers expect the same results from 3d printing technology. The main materials which they use are as follows:

- aluminium

- stainless steel

- Hout enz.

Hence by using these technologies they will have the ability to fabricate or create complicated designs in just few hours.

But there is also a problem while processing with CNC machines. Unluckily there are several prototype projects that actually need manual handling. By the use of manual handling, engineers complete the manual treatment. Because they cannot be developed by the use of CNC machines.

So, in metal sheet manufacture, processing cannot be completed by the run-time of CNC. Hence, CNC machines processing may be limited for several functions in comparison to manual handling.

What are some advantages of CNC Rapid prototype en CNC-metalen onderdelen ?

Main essential benefit of CNC Rapid prototype against 3D printing is that, there is less limitations of materials. And the great grand advantage of CNC machines is that using it engineers fabricate prototypes with the help of a huge range of metals and plastics.

And these materials are:

- koper

- aluminium

- steel

- brass

- titanium

Many other materials are:

- foam

- wood

- fiberglass

Although there is a vast variety of materials which are available for plastic 3D printing. And many of them also have the great quality of durability. Hence, engineers use CNC Rapid prototype & CNC-metalen onderdelento bulk of production. Because other materials do not even permit them for functional testing.

Some advantage of CNC Rapid prototype & CNC-metalen onderdelenagainst 3D printing

The technology of Metal 3D printing which is actually famous as the name of Direct Metal Laser Sintering or (DMLS), has using rapidly by various companies. And it is also very successful technology for the following, like:

- aerospace industries

- Automotive industries.

And it is also famous with the name of Selective Laser Melting (SLM).

Although these 3D printers are very expensive. And these printers have also ability to design prototypes for complicated parts. Because engineers cannot create them by CNC machines. And they cannot substitute by CNC machining for whole parts.

But both of these techniques are part and parcel in order to create a CNC Rapid prototype. And also, for creating prototypes for final production parts.

There is also a great advantage of CNC machining is that it has the ability to remove massive amount of material rapidly with a great precision. And the other key benefit is its ability of tight tolerances.

It is standard when we achieve +/-0.01mm from CNC machines. But machines that are 5-axis have the capability of getting +/-0.005mm. But getting this level of efficiency with the help of 3D printer need the layer to be below 0.005mm. Subsequently, it means that there is need of very long time for print even a very small part.

Hoe werkt CNC Rapid prototype en CNC-metalen onderdelen starts with 3D?

If engineers really want to get benefit of CNC Rapid prototype en CNC-metalen onderdelen, then their procedure of product development requires to occur in an environment of strong 3D. So, in this way, engineers can transform the model of 3D within data in order to prototype with least effort.

Luckily there is no lack of design apparatus of 3D product in order to help you. Other tools like:

- renderer work

- CAD

Hecht soepel met elkaar. En stelt ingenieurs ook in staat om van één technisch ontwerp naar 3D-prototyping te gaan met een identieke procedure. Om heel eenvoudig CNC-ready modellen te fabriceren zijn twee gereedschappen nodig, zoals:

- modules

- plug-ins

Werk dus gewoon samen met uw beste serviceproviders om de stijl te begrijpen die u wilt gebruiken voor snelle prototyping. En u kunt hulp krijgen van goede serviceproviders om de beste resultaten te fabriceren.

De beste dingen die u moet weten over CNC Rapid prototype en CNC-metalen onderdelen

Dit zijn de dingen die u moet weten over CNC Rapid prototype en CNC-metalen onderdelen en 3D-printen voor rapid prototyping.

Here are some important things you must need to understand about 3D printing and CNC for the purpose of rapid prototyping. When you will get complete information about the latest and advanced technologies, you can easily design the products that customers will surely love.

Many people believe that rapid prototyping and 3D printing are same. Rapid prototyping is basically a rapid and also very cost efficient. They are used to test, design and verify before you make the final development in your final products.