Why is High Precision CNC Machining So Important?

25-08-2020High Precision CNC Machining: What Merits Does it Offers?

OEM engineer leaders are presented with new challenges every-day due to innovative technology and always-expanding global market. They are searching for ways to increase profit margin, satisfy their consumers, and entice consumers with uniqueness. High Precision CNC Machining is perhaps an effective way to retain a competitive edge.

In this blog post, we are going to provide you with a detailed introduction to high precision machining, its benefits, and why it is so important. So, without any further delay, let us get started!

Introduction to High Precision CNC Machining

What is High Precision Machining?

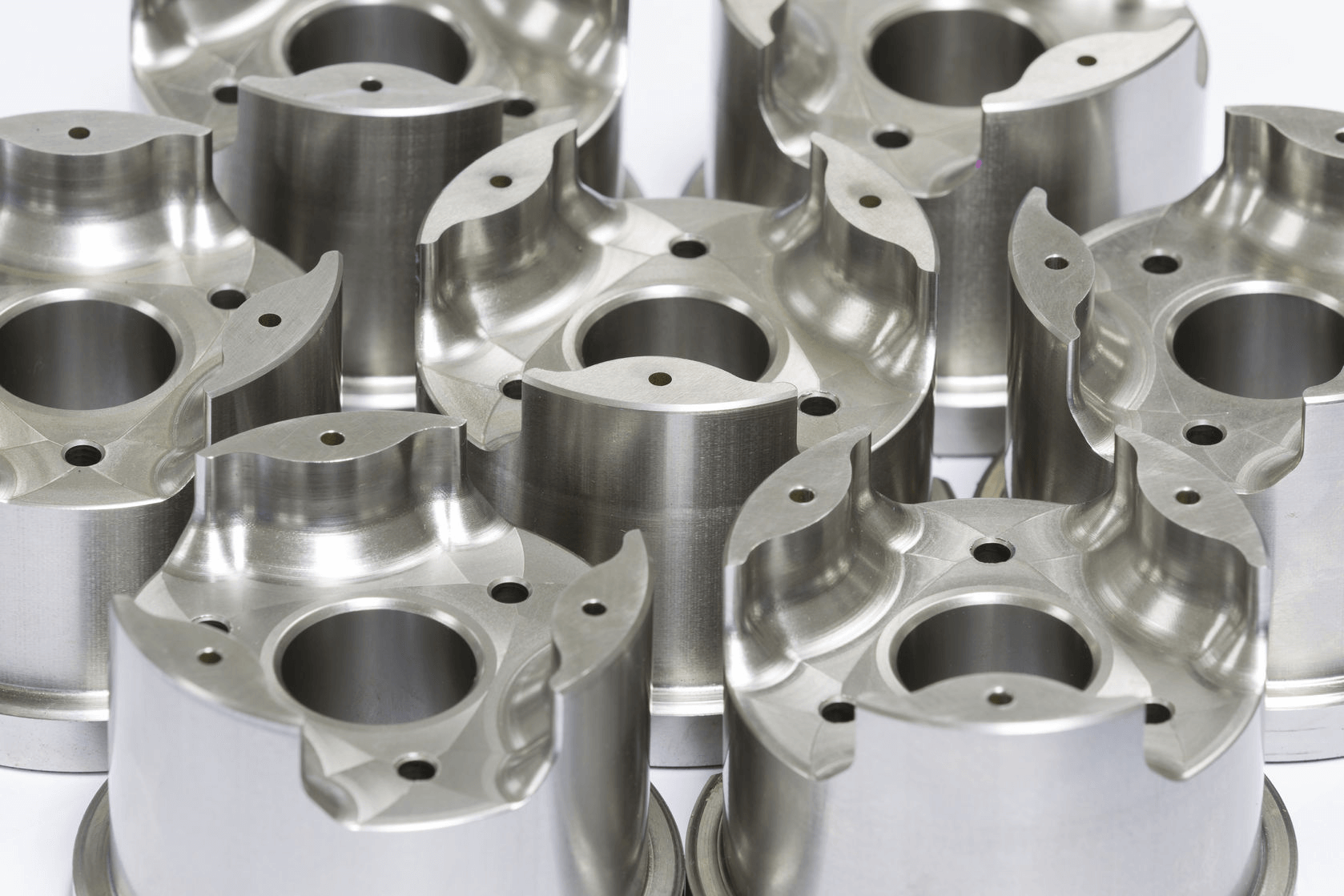

It is a process that uses raw material from an object to create finished products of a smaller size. The process involves a number of cutting machines, human engineering techniques, and software applications.

Being an extensive process that requires utmost care and complete attention. Firms that need third-party organizations for the production of their machine parts, would also rely on other companies for precision machining work.

There are many reasons for outsourcing the work, either the company is overwhelmed by all the extra work, it is a small shop that can not afford the CNC-bewerkingsmachines . There is no harm in outsourcing, however, it important to consider all your option before hiring a third-party.

CNC Machining Technology

Modern and sophisticated manufacturers prefer products and parts to meet the exact, provided dimensions. Therefore, manufacturers today rely on Computer Numerical Control machines. For instance, there are certain manufacturers who have built their own multi-axis CNC milling. They are turning these machines into their shops.

Advantages of the High Precision CNC Machining

Below, we have listed the advantages of outsourcing and using precision machining

Low Error

The chances of error are nullified when using a Precision CNC machining. All you have to do is to ensure that you enter the correct specifications. Once you key them in, the automated precision machining method takes over.

Here, the chances of error are very low especially when compare it with the human machining. Outsourcing this work would eliminate your need for higher highly skillful and experienced staff required for machine operations.

Less Material Waste

Since the main purpose of precision machining is subtraction, so it goes without saying that significantly reduces material waste. After all, there is great potential for material wastage especially in the case of human machining.

However, using precision machining would reduce the material cost. You can save additional on your material cost in you hire a professional precision machining company.

How? These companies buy material in bulk. Thus, it would cost them less and they would pass on the savings to you.

Precision CNC Machining offers consistency

With precision machining, it is possible to achieve consistency from time to time. Every product or part would be of the same quality and excellence. Even if you produce them in multiple batches, the quality of the products or parts would remain consistent.

This consistency in terms of premium quality would lead to greater customer satisfaction and increase customer leads. It would also enhance customer confidence in your brand.

Improved Workflow

Companies that allow their engineers to work on product development instead of tiny design changes are always able to manage the opportunity costs. So, when you reach out to a professional precision machining service provides, they would be making minor modifications during the prototype process.

This is to make sure that the product is according to the requirement as well as the industry standards. Since the company would be doing the tedious and meticulous work, it would leave you engineers ample time to work on product development.

Reduced Turn around Time

With Precision machining, there is no denying the turn around time reduces significantly. After all, the machine is able to perform in an effective and efficient manner than humans. So, even if you have an in-house precision machining system or you are going to hire a third party, you would witness reduced turn-around time.

However, reaching out to an experienced company would further reduce the turn around time. Since they have a running business, all the equipment and labor are in place along with immense experience. The third-party precision machining company would yield more effective and efficient results.

Production Cycles

Met High Precision CNC Machining, it is possible to introduce your product at a much faster pace. This would give you the edge and the flexibility to establish your product against companies that still rely on conventional methodologies.

What more is that you will be able to update and upgrade your product as per the changing customer requirements and industry standards seamlessly.

Prototype Testing

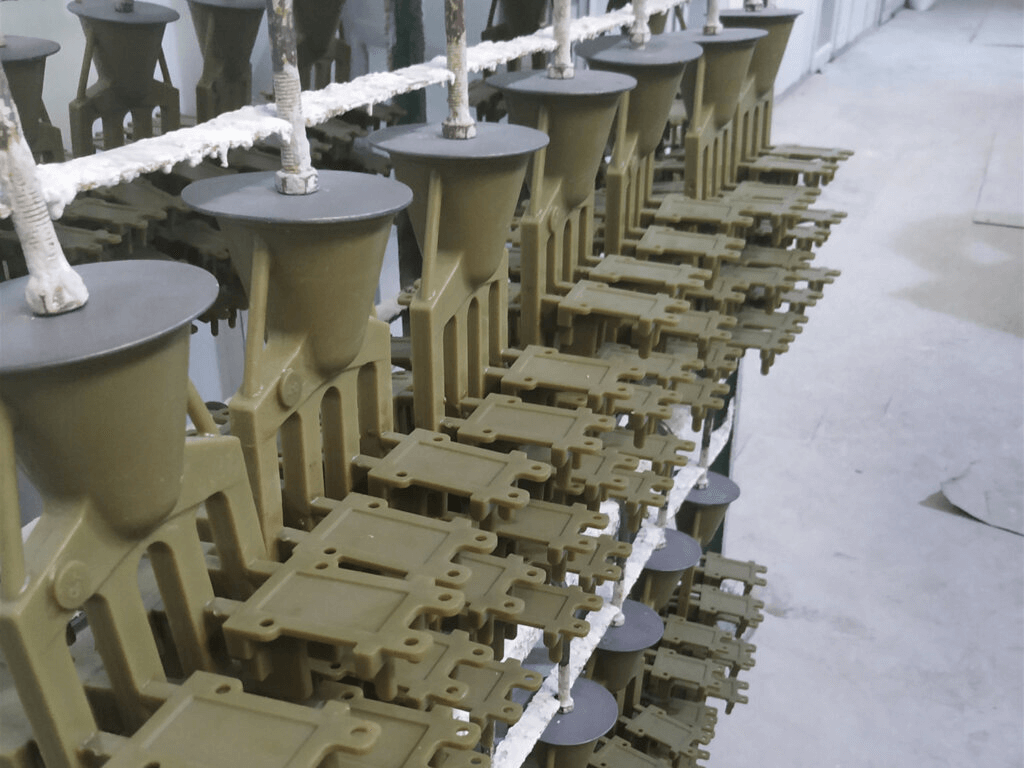

With precision machining, it is now possible to explore the market’s smaller niche that has the potential of higher returns. As you are determining the niche opportunity, you can use the precision machine’s flexible product development phase. In case, your product has a market scope, you can effortlessly shift to a full-scale production model.

Unlike the concept prototypes, precision machining prototypes offer functionalities. They would provide you with a clear picture of how your product would feel, look, and work in the real environment.

Also, functionality prototypes attract investors' attention in a better way as compare to the only-concept prototypes.

Importance of High Precision Machining

High Precision CNC machining has evolved to become an important part of the manufacturing cycle. It offers efficiency, accuracy, and effectiveness. Precision machining has become imperative across industries.

Below are some of the industries that greatly use high precision machining.

Medical Device Industry

Orthopedic and cardiovascular devices greatly rely on the EDM and the 5-axis milling. In addition, there other implants and surgical instruments use this precision machining to produce consistently high-quality parts and components.

Medical CNC Machining

There are several factors that have a direct impact on the medical procedure’s outcome. The same rule applies to the medical CNC machining. When the equipment is able to control dust and temperature, it can guarantee high precision results. Also, it needs to ensure an ideal environment for every process along with stringent tolerance.

Surgical Scissors

These are perhaps one of the most important tools. Doctors use them in almost every medical procedure. They serve multiple purposes. For instance, doctors use them to get into the skin or to sew.

These scissors come in a wide range of sizes and shapes. Therefore, are well-equipped for different processes. For example, the surgical scissors that are required for eye surgery are extremely small. These scissors require precision and consistency in terms of quality.

Therefore, surgical manufacturers choose reliable, professional, and experienced CNC machine shop.

Cannula

Vein cannula is a popular medical product as they are in popular demand in medical centers almost in every part of the world. Like numerous surgical instruments, these products come in a wide range of sizes and shapes. They are like the needle gauge.

To manufacturer high precision casing, manufacturers need to use wire EDM or the Multi-spindle milling. As both of these are the most sophisticated CNC available.

Saws using during Orthopedic Surgery

Since orthopedic surgeon requires high precision equipment. The reason being, they have to cut into the human bones using sawing. Accurate and precise saws will help you cut as quickly as possible without going very deep.

Om de precisie en kwaliteit van elke zaag te garanderen, is het belangrijk om te vertrouwen op een professionele, uiterst nauwkeurige CNC-bewerkingsfabrikant.

Vliegtuigen

De moderne en geavanceerde vliegtuigen zijn niet langer afhankelijk van canvas tweedekkers en houten draad. Hun steeds groter wordende behoefte aan precisie en complexiteit vereist iets groters en robuusts.

Vliegtuigen hebben nu consistentie, duurzaamheid en stevigheid nodig. Het is niet mogelijk de complexiteit van de huidige vliegtuigen te overdrijven. Ze hebben vliegtuigturbines, decoratieve systemen, geavanceerde avionica, geavanceerde motoren en hydraulische oppervlakken.

Al deze componenten zouden geavanceerde en hoogwaardige componenten vereisen om correct te functioneren. Terwijl u de vliegreizen opbouwt, is het absoluut noodzakelijk dat het vliegtuig de beste componenten heeft om veilig, betrouwbaar en efficiënt te werken.

Het belang van precisiebewerking in onderdelen van de militaire luchtvaart en burgerluchtvaart valt niet te ontkennen. In sommige gevallen zouden de precisiebewerkingsingenieurs het algehele toepassingsniveau opnieuw ontwerpen om de functionaliteit te verbeteren.

5-assige CNC-bewerkingsmachine is een geweldige manier om de nauwkeurigheid en kwaliteit van onderdelen te garanderen. Het wordt gebruikt voor vliegtuigonderdelen. Het heeft ook een geweldige tijd rond de tijd.

Hoge precisie CNC-bewerkingsbanen

Qua klussen is de CNC-bewerking van groot belang. Fabrikanten zijn altijd op zoek naar ervaring in bedrijfsbeheer, teamleiderschap en de volgende gebieden.

Specialisten of gereedschapswerkers

Er is een wijde wereld voor mensen die bedreven zijn in CNC-bewerkingsgereedschappen. Enkele van de rollen zijn onder andere draai-impressie, productie van toolset, basiskennis van programmeren, ontwikkeling van armaturen, ontwerp van armaturen, onder andere.

Machinisten

Dit omvat verschillende rollen, variërend van vloerbedieners tot operators.

Samenvatting

Precisie CNC-bewerking is de nieuwe manier om hoogwaardige, geavanceerde onderdelen te produceren en tegelijkertijd de nauwkeurigheid batch na batch te garanderen. Om ervoor te zorgen dat het hele project soepel verloopt, moet u echter een professionele, uiterst nauwkeurige fabrikant kiezen.

Bij Essaii bieden we hoogwaardige CNC-precisieservice . Neem vandaag nog contact met ons op voor meer informatie.