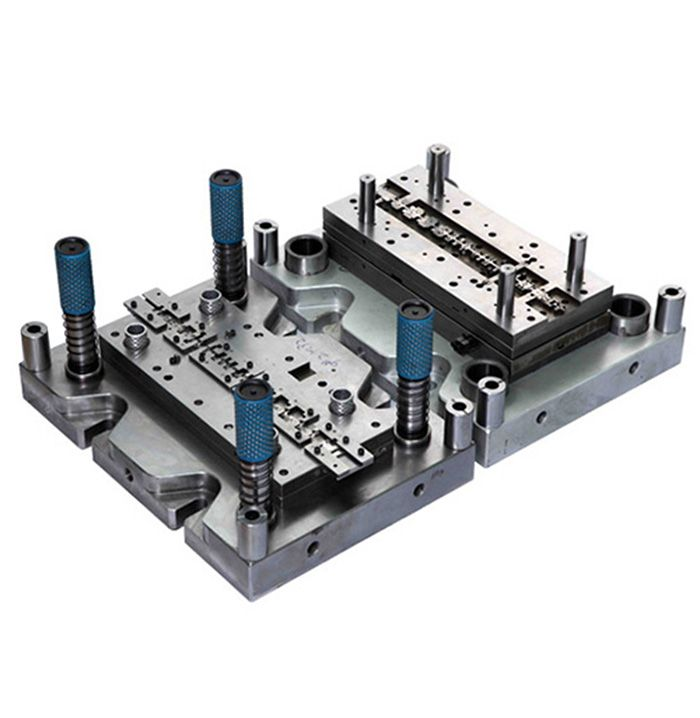

Application of Proactive Stamp Tool in Die Casting

2021-09-12Rules for the operation and maintenance of stamp tools

Correct use and customer service of the stamp tool is very important to keep the tool in good working order for a long time, while reducing your tool costs. The increase in tool life depends on the following factors:

- Applying the correct die gap in accordance with the type and thickness of the material

- The alignment of the tool in the turret and the serviceability of the seats in the revolver

- Application of various types of protective coatings for tools

- Regular sharpening of the tool according to the specified recommendations

- When stamping a large number of identical holes, it is necessary to use two tools

- Lubricate the sheet

- Ensure automatic supply of lubricant to the tool

Tool alignment in the revolver

Revolver adjustment is a procedure that can help prevent a sharp decline in stamp tool life, product quality and prevent wear of the revolver. It is recommended to periodically inspect the alignment of the stations in the revolver. The alignment check is carried out using a special alignment tool.

The adjustment carries out in accordance with the service instructions for this type of equipment. It is also necessary to check the condition of the tool guide.

Application of a protective coating for punches

Exacta Precision is one of the leading companies in the heat treatment and surface treatment of tools and accessories. The company was one of the first to introduce ion-nitride, cryogenic treatment and now offers a full range of surface coating treatments. All Thick stamp tool guides are vacuum hardened, nitrided to harden the surface layer and resist abrasion, fatigue and corrosion.

Ø The titanium carbonitride

The titanium carbonitride (TiCN) coating is silver to bronze in color. The thickness of the coating layer is 2-5 microns. The achievable hardness of the coating is 66-70 HRc with high abrasion resistance. Whether you need to stamp abrasive or heavy-duty steels, titanium carbonitride coating is your choice.

Ø Chromium nitride (CrN) coating

It is usually silver in color with a hardness of 62-64 HRc. The thickness of the coating layer is 2-5 microns with increased adhesion. This property makes this coating indispensable for drawing or stitching operations.

Lubrication of the processed sheet and stamp tool

Practical experience with the stamp tool confirms that the lubrication of the surface of the sheet increases the life of the tool. For this purpose, a variety of punching, stamping and cutting lubricants have been developed. In turn, the lubrication of the tool itself also increases its resistance to wear.

The oil film creates a protective layer on the working part of the punch and reduces the adhesion of particles of the processed material to the punch. Punches without a lubrication system are recommended for use with graphite or molybdenum based lubricants. The rubbing surfaces between the guide and the tool holder in the revolver are lubricated with liquid oil.

Use of pads in stamp tools

Shims can be common to increase the stamp tool life - dies of all stations and punches. Shims are common after regrinding of punches and dies. Punch shims provide the required length of the punch assembly after sharpening. Die shims provide the necessary penetration of the punch into the die and exclude sheet deformation.

Spacers should be made of steels with increased hardness and thickness accuracy. The use of warped shims can result in misalignment of the tool, reduced tool life, or destruction of the die holder.

Use of punch sleeve

The use of a special punch sleeve in the A and B stations of the Original style during its reversal provides an increase in the size. For C and D stations, the use of shims increases the possibility of punch re-sharpening up to 4 mm. But you need to be very careful, because exceeding this size of shims can disengage the punch from the dowel key and cause damage to both the stamp tool and the machine.

Feature of processing thick materials

When processing thick steel plates with a thickness of more than 3.0 mm and stainless steel with a thickness of more than 2.0 mm, the following recommendations must be adhered to:

- Use a punch with a large reverse angle - up to 1 °

- Minimum punch size 6.40 mm

- Moreover, radius at the edges of the punch not less than 0.5 mm

- Obligatory sheet and tool lubrication

- Processing is carried out at a reduced speed

Stamping force

Observe the required stamping force. The stamping force should not exceed 80% of the maximum press force. Important: when stamping with stations C, D and E, the spring compression can be common from 10% to 20% of the press force.

Use stations A and B of Heavy Duty type

We recommend stamping using the bridging method - this contributes to an even load on the punch. One-sided stamping is not recommended if less than 70% of the punch length is involved.

Cluster stamp tool processing

Processing with a cluster stamp tool can significantly reduce the processing time of a perforated sheet, with a higher quality than processing with a single tool. When processing with a cluster tool, the total number of strikes on the sheet is reduced.

Why re-punching the holes are not good?

Do not re-punch the holes with a cluster on existing holes, because doing so will skew the tool and possibly damage it. If the multiplicity of the rows of the cluster does not allow performing the entire perforation without re-punching, then it is necessary to finish the processing with a single tool.

Using die casting often no further machining is important after molding. It has accuracy of 99.8%, but die cast products is also good to use raw. They still have an aesthetically pleasing finish. Of the zinc common in the world, about 28% is good in the automotive industry.

Summary stamp tool

Zinc has become one of the most important metals in stamp tool industry, especially for products such as:

- lock housings

- pawls

- retractors and pulleys in seat belt systems components.

By using this metal and its alloys, it is possible to achieve a strength, ductility and malleability impossible to obtain with other materials.