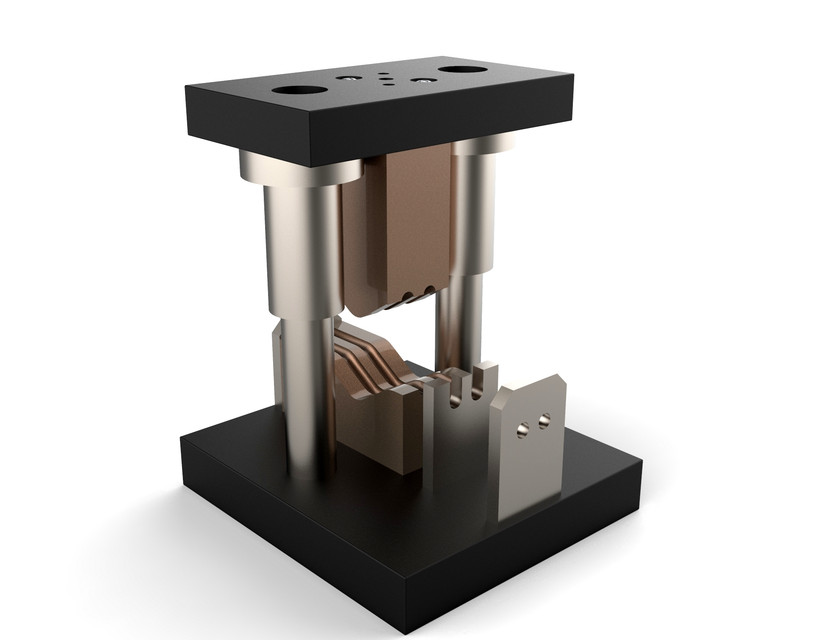

What is the function of export progressive tool?

The design of open and closed export progressive tool has only one, but very significant difference. The former have a special gap that receives excess metal squeezed out of the progressive tool strands. This gap allows export progressive tool without the need to calibrate the mass of work pieces with high accuracy: excess metal (if any) is […]

What is complete process of metal stampings?

Types and methods of modern metal stamping Firstly, metal stampings is a controlled deformation process in which a body changes its shape under the influence of excess pressure. Thanks to this processing, metal products are given a wide variety of forms that they need to fulfill their functional duties. Parts of small thickness lend themselves to stamping, since […]

All You Need to Know About Aluminum Stamping

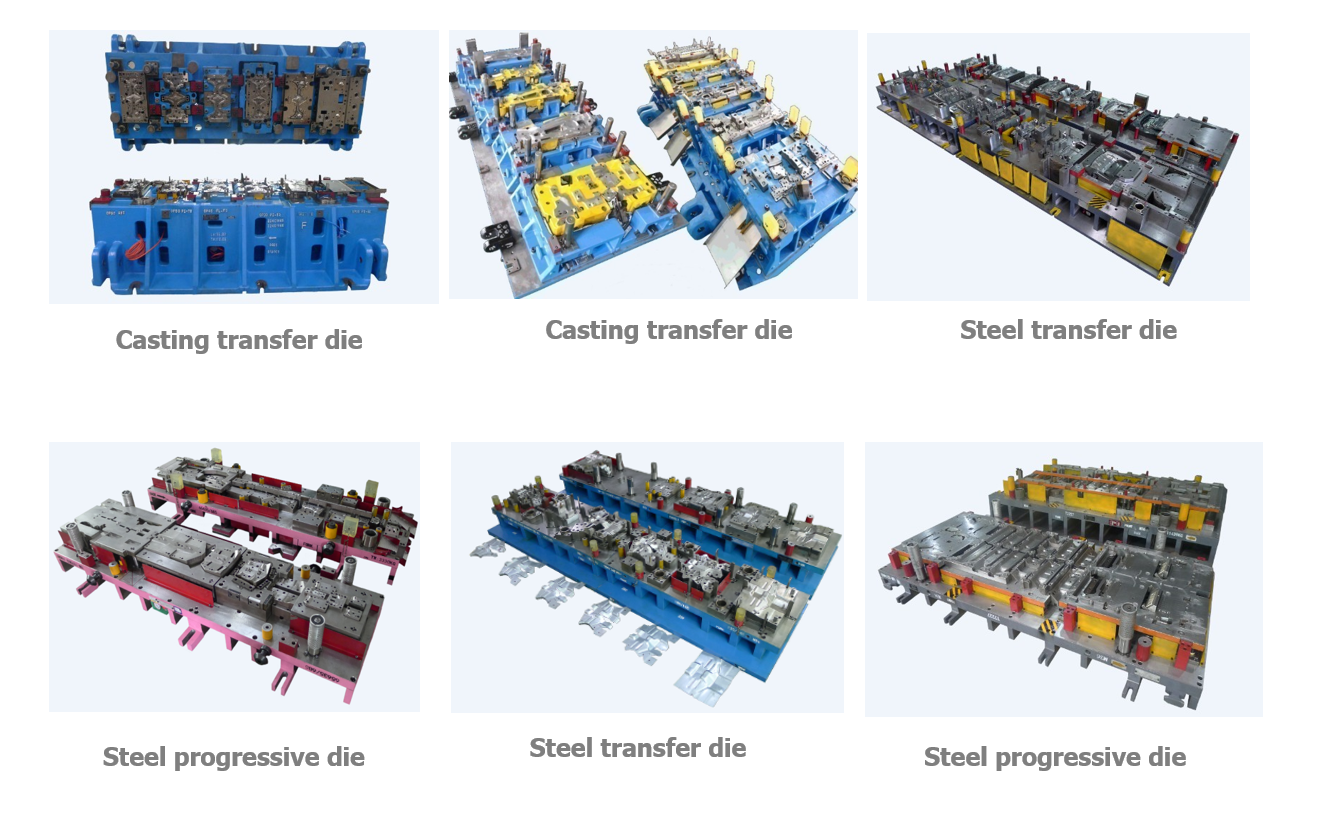

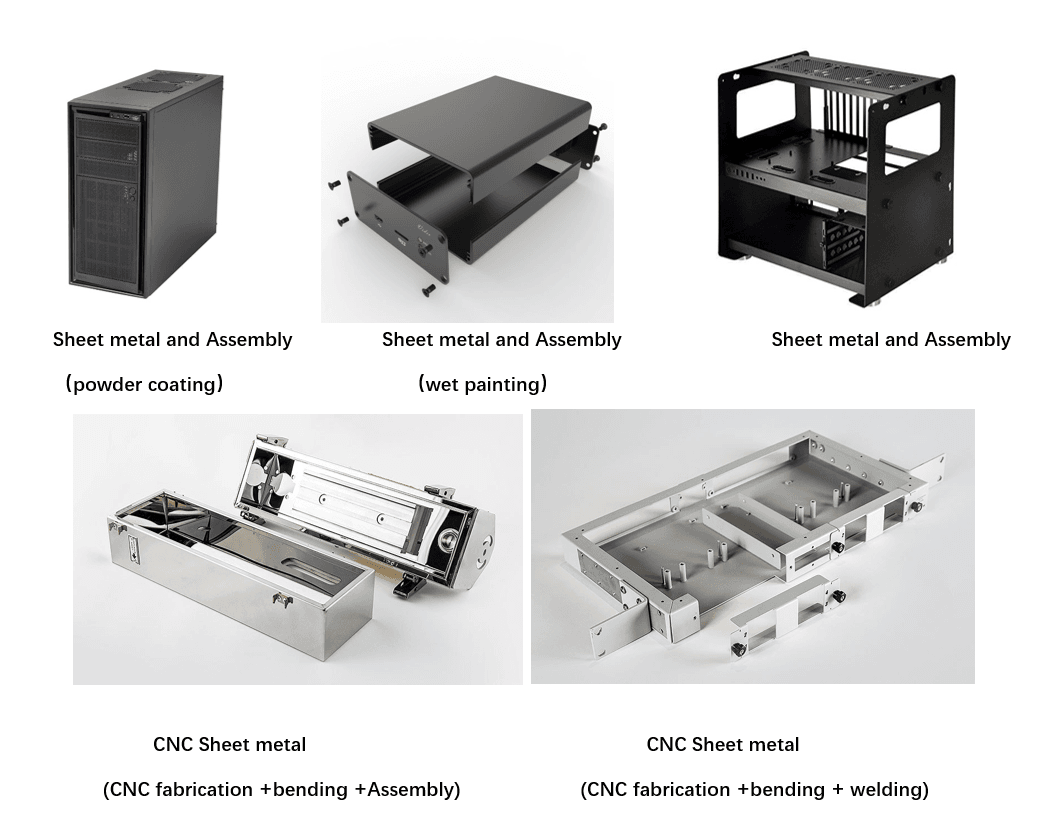

All You Need to Know About Aluminum Stamping, Stainless Steel Stamping, Pressure Die Casting, and CNC Bending The metal stamping process converts flat sheets of metal into different shapes. Stamping is also known as pressing. To obtain a new shape out of a flat sheet, the flat metal sheet is placed in either blank or […]

What is metal stamping? 2 Best types for Beginners

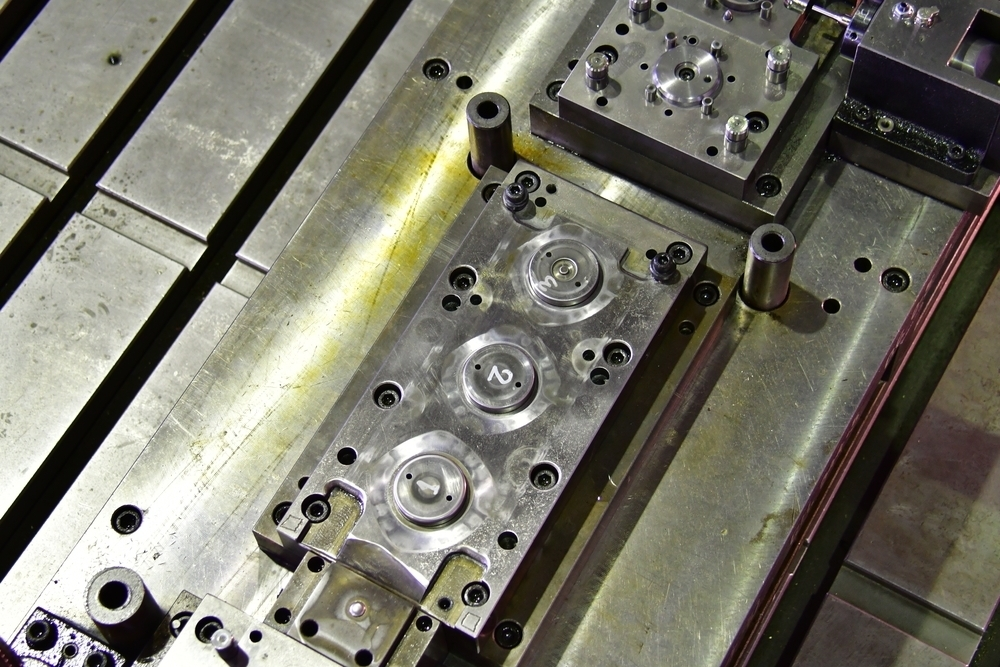

Types and methods of modern metal stamping Metal stamping: technology features. It is an alternative method of plastic deformation of metal: cold and hot sheet and die forging. Moreover, this includes cold stamping technological operations. Used Press Equipment and Automatic Lines. Stamping is a technological operation that controls process of changing the shape and size of a work […]

7 Steps for Perfect High-Precision Stamping Part Manufacturing

High-precision stamping part is the shaping of a material under the action of an external force in order to obtain the desired part. It takes a lot of effort to machine the work piece in this way. Moreover, for this, there is equipment that comes with an effort of 16 to 500 tons. The tooling installed in the […]

Metal stamping supplier: 4 Types of Punching Metals

What is metal stamping processing? Metal stamping supplier provides the process of forming metal sheets in a desired shape using different manufacturing methods. The completion of a product usually involves many steps, from cutting and bending to surface treatment and assembly. Often, fabrication techniques are easy to use to achieve similar end results, but the right choice […]

5 Most Common Metal forming Tools we Use in laser Cutting

Along with nonmetals and nonmetals, metal forming tools are also distinguished by their degree of ionization. In the periodic table of chemical elements, metals make up about 80% and nonmetals and nonmetals make up about 20%. Classify Physical and chemical properties of metals Physical properties Chemical properties Applications of metals in today's life What is metal? Metal properties […]

For what purpose is metal stamping kit we use?

Turning a part: using metal stamping kit and solving the problem I am often asked about the secrets of making metal stamping kit. Turning process of a part despite having many years of experience as a turner, this question baffles me. You cannot answer with one sentence, and I don’t want to turn the dialogue […]

7 Advantages of Bending Die in Practical Field

Bending die processing: principle of operation, advantages, application Bending die of metal is carried out with a laser beam. Compared to conventional light, the laser is directional, monochromatic and coherent. Moreover, these properties provide the most accurate focus on a small metal surface. Generally, the concentration of energy allows the material to get heat. Furthermore, gas and solid-state lasers […]

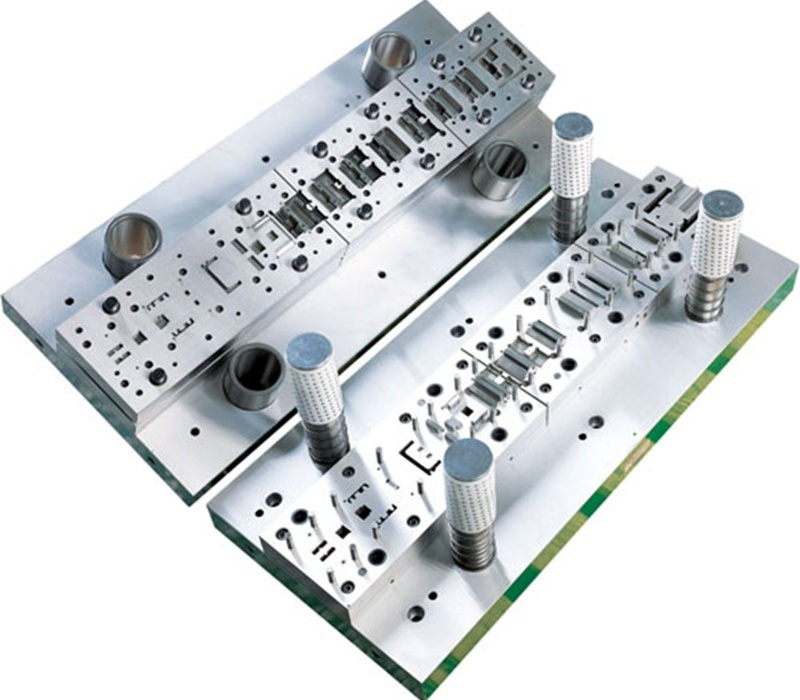

What is progressive stamping tool? Step by Step Guide

Progressive stamping tool is the finishing of a work piece. It is necessary to obtain a smooth surface of the part. With the help of grinding, minor defects of previous operations are eliminated. This process is subdivided into several types: Rough Flat Round grinding Sharpening Polishing I must say that this process is quite laborious. This requires special tools […]