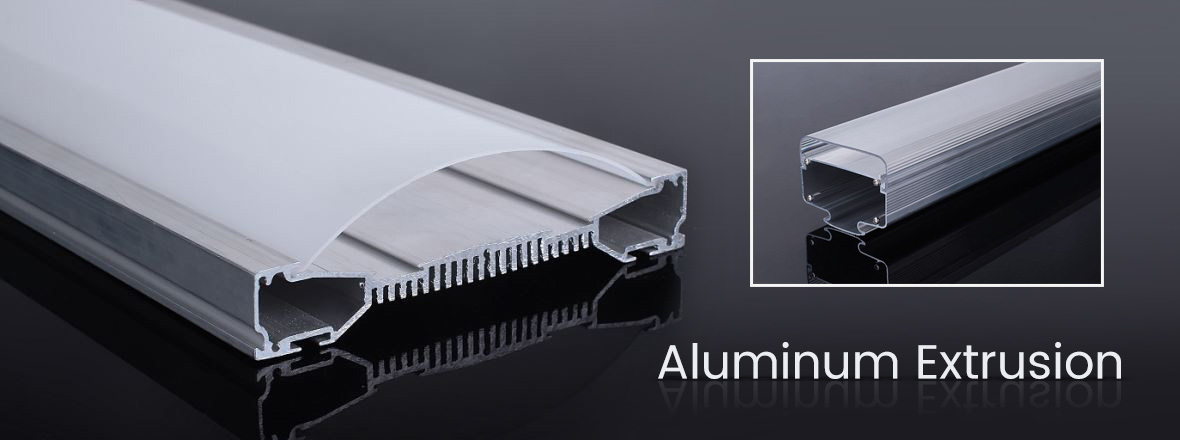

Aluminum Extrusion

Essaii are the manufacturer focus on industrial aluminum profile, standard slot profile, heat sink , assistant accessories ect .The extrusion tool could be finish within 10days for tight schedule project. .We have the certificest including ISO14004:2015 & GB-T19001-2016-ISO . We are your reliable partners now and in the future .

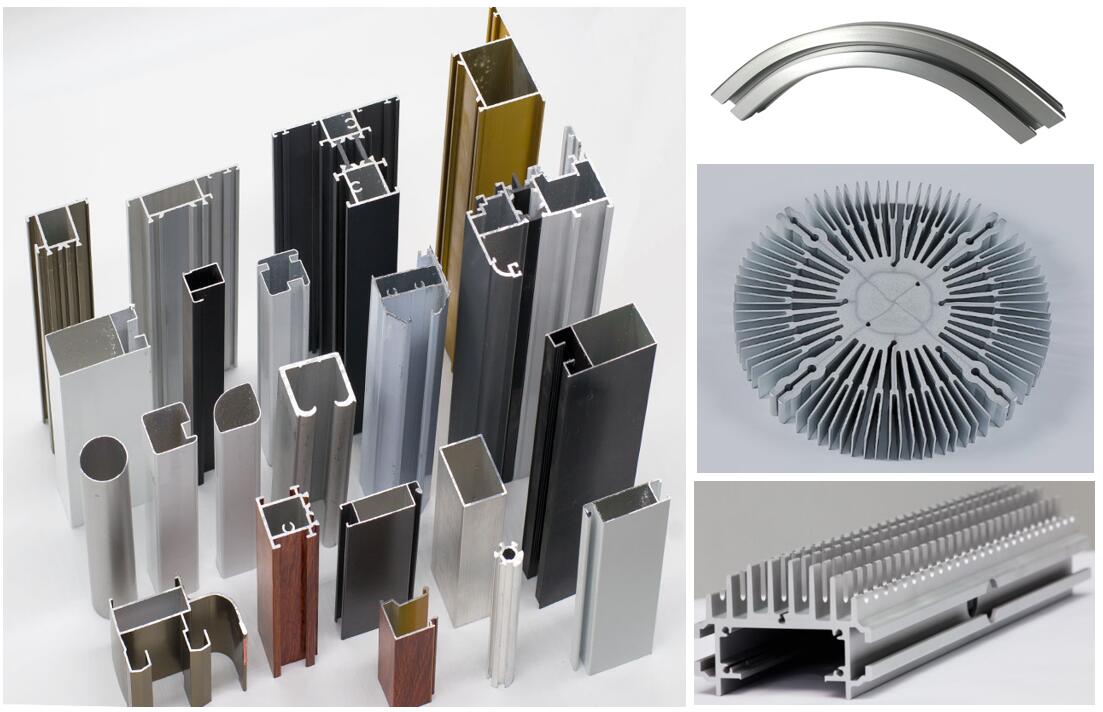

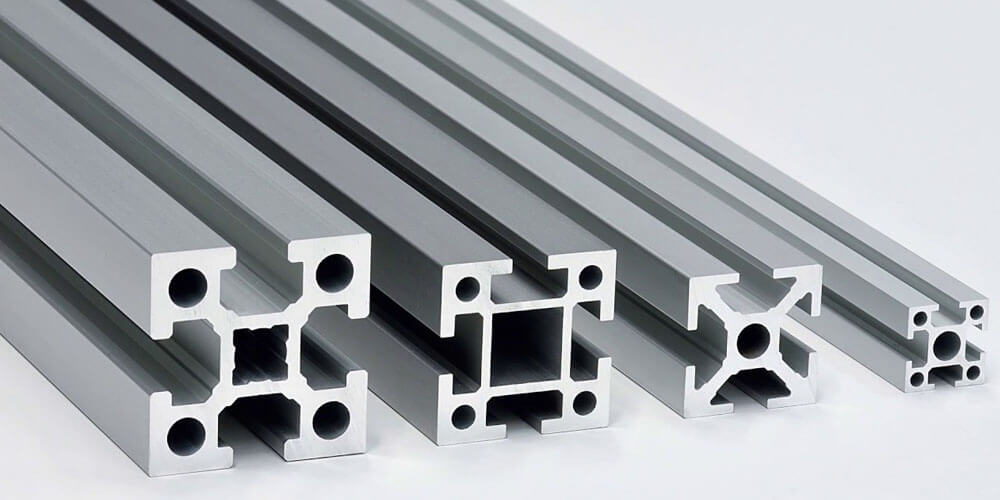

Essai can provide complete manufacturing solutions for aluminum extrusion products, including surface finishing, machining, cutting, and assembly. The alloys used include AL6060, AL6063, AL6061, AL6005 and AL6082.We extrude various aluminum alloy series in the finishing process from 6 'to 25', we provide a wide range of custom molds to suit various shapes and sizes (Grooved, hollow or solid), so we encourage you to send us your design for a quote.

1. Improve the deformability of metal

The extrusion ratio of pure aluminum can reach 500, the extrusion ratio of pure copper can reach 400, and the extrusion ratio of steel can reach 40-50. For some low-plasticity and difficult-to-deform metals and alloys that are difficult to process or even cannot be processed by other methods such as rolling and forging, even brittle materials such as cast iron can be processed by extrusion.

2. High comprehensive product quality

Extrusion deformation can improve the structure and mechanical properties of metal materials, especially for some aluminum alloys with extrusion effects. After quenching and aging, the longitudinal (extrusion direction) mechanical properties of the extruded products are much higher than other processing methods. Production of similar products

3. Wide range of products

Extrusion processing can not only produce tubes, rods, and wires with simple cross-section shapes, but also can produce solid and hollow profiles with very complex cross-section shapes, and the cross-section profiles of products that change in stages and gradually change along the length. The range of sizes is also very wide, from ultra-large pipes and profiles with a diameter of 500-1000mm outside the cross-section to ultra-small precision profiles with a cross-section-like size.

We have 10 domestic advanced entire automated productions running water production lines, more than 40 domestic advanced production equipment, mature technology, and work team.

1. According to your design ideas or drawings.

2. We can provide your with the best raw material, excellent price, cost-effective.

3. In strict accordance with ISO quality control Richard, we will strict material control, will purchase of high purity aluminum of raw material of aluminum alloy.

4. We will Formulate a reasonable production plan and establish corresponding follow-up system unification, the responsibility to the person; The delivery date is guaranteed according to customer requirements. Arrange production, urgent order, quick order quick processing, to meet customer urgent supporting production of single/small orders.

5.receive design-design-tool make-produce-post process-surface finish.

6. The products can do all kinds of color or processes depend on your request, such as sandblast and anodize, etc.

| Aluminum alloy | Alloy 6063/6061/6005/6060 T5/T6 |

| Temper | T3-T8 |

| Surface treatment | mill finish, sandblasting, anodizing, electrophoresis, polishing, power coating, PVDF coating, wood transfer, etc. |

| Color | Bronze, golden, silver, black, white, red, blue, etc. |

| Thickness | customized |

Welcome To Start Your Business Now!

Contact Us