Protótipo de Método de Produção de Peças Metálicas

03/06/2020Protótipo de métodos de produção de peças de metal

Protótipos de fundição de metal, protótipo de peças de metal 2020

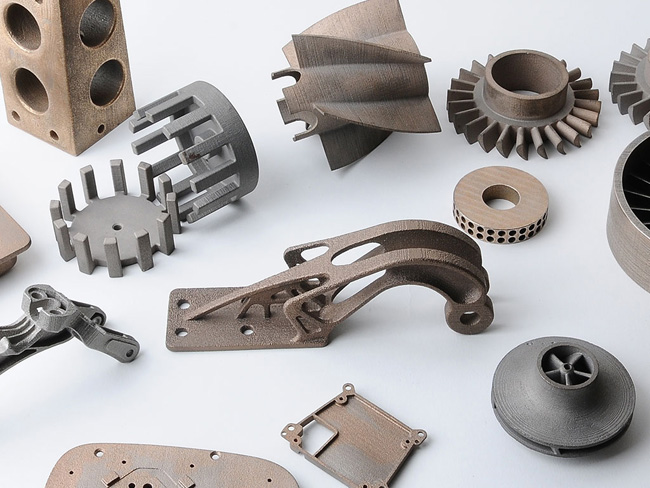

Quando se trata de completar a fabricação de peças de metal, existem muitas maneiras de os usuários abrirem, primeiro usando tecnologias tradicionais (como CNC e fundição) e, finalmente, impressoras 3D. Escolher a opção certa é muito difícil, mas a equipe de engenheiros profissionais da Xometry resume várias tecnologias e descreve suas principais vantagens.

Sinterização direta de metal a laser (DMLS)

With DMLS, users can create rather complex geometric shapes, which cannot be done using more traditional methods. In addition, the strength of metal parts is almost the same as the strength of fully cast, their advantage is that each element can be created at different times.

The most suitable metals for DMLS are Extrusão de alumínio and stainless steel. The technology itself is more suitable for:

- Create parts with complex geometries;

- Production of spare parts for outdated systems;

- Small products and functional prototypes.

Metal binder spray

This option is an economical solution and has several advantages over the previous one. Materials such as stainless steel and bronze inclusions (40% to 60%) can be used here

MBJ is suitable for creating:

- Cheap metal parts;

- Products created by DMLS cannot be used due to size;

- Spare parts with high corrosion resistance.

Rapid CNC machining

Using CNC machine tools, high-precision parts with high-quality surfaces can be created. Users can use a variety of metals and have precise tolerances and various roughness options. For those who need to quickly manufacture any part and start using it immediately, CNC is a good choice.

Use the machine for the following items:

- High-quality materials are required;

- Have strict tolerance;

- Create in proportion;

- Improvements are needed, including anodizing, metallization and spraying.

Processamento de chapa metálica

With sheet metal, you can create thin-walled parts that cannot be created using milling machines or other techniques. The product itself can be made of aluminum, copper, stainless steel, steel and zinc.

The metal plate is best for:

- Parts with thin metal walls;

- Create brackets, boxes, boxes and chassis;

- Light parts.

People all over the world have been arguing about something better-using traditional production methods or 3D technology. But the answer is always in the middle as usual-each technology has its own advantages and disadvantages, but they can complement each other perfectly and can be used to manufacture truly high-quality parts.