Prototype of metal parts Production Method

2020-06-03Prototype of Metal Parts Production Methods

Metal Casting Prototypes, Prototype of metal parts 2020

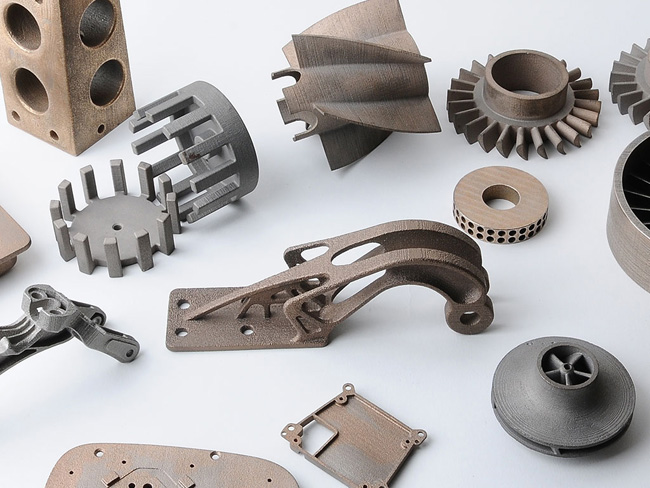

When it comes to completing the manufacture of metal parts, there are many ways for users to open, this is first to use traditional technologies (such as CNC and casting), and finally 3D printers. Choosing the right option is very difficult, but the Xometry team of professional engineers summarizes various technologies and describes their main advantages.

Direct Laser Metal Sintering (DMLS)

With DMLS, users can create rather complex geometric shapes, which cannot be done using more traditional methods. In addition, the strength of metal parts is almost the same as the strength of fully cast, their advantage is that each element can be created at different times.

The most suitable metals for DMLS are Penyemperitan Aluminium and stainless steel. The technology itself is more suitable for:

- Create parts with complex geometries;

- Production of spare parts for outdated systems;

- Small products and functional prototypes.

Metal binder spray

This option is an economical solution and has several advantages over the previous one. Materials such as stainless steel and bronze inclusions (40% to 60%) can be used here

MBJ is suitable for creating:

- Cheap metal parts;

- Products created by DMLS cannot be used due to size;

- Alat ganti dengan ketahanan kakisan yang tinggi.

Pemesinan CNC pantas

Dengan menggunakan mesin CNC , bahagian berketepatan tinggi dengan permukaan berkualiti tinggi dapat dibuat. Pengguna boleh menggunakan pelbagai logam dan mempunyai toleransi tepat dan pelbagai pilihan kekasaran. Bagi mereka yang perlu dengan cepat mengeluarkan mana-mana bahagian dan mula menggunakannya dengan segera, CNC adalah pilihan yang baik.

Gunakan mesin untuk item berikut:

- Bahan berkualiti tinggi diperlukan;

- Mempunyai toleransi yang ketat;

- Buat mengikut perkadaran;

- Penambahbaikan diperlukan, termasuk anodisasi, metalisasi dan penyemburan.

Dengan kepingan logam, anda boleh membuat bahagian berdinding nipis yang tidak dapat dibuat menggunakan mesin penggilingan atau teknik lain. Produk itu sendiri boleh diperbuat daripada aluminium, tembaga, keluli tahan karat, keluli dan zink.

Plat logam sesuai untuk:

- Bahagian dengan dinding logam nipis;

- Create brackets, boxes, boxes and chassis;

- Light parts.

People all over the world have been arguing about something better-using traditional production methods or 3D technology. But the answer is always in the middle as usual-each technology has its own advantages and disadvantages, but they can complement each other perfectly and can be used to manufacture truly high-quality parts.