ፈጣን ፕሮቶታይፕን በተመለከተ የመጨረሻ እና ሁሉን አቀፍ መመሪያ | ቻይና

2020-06-07ፈጣን ፕሮቶታይፕ: - ማወቅ ያለብዎ ነገር ሁሉ

ፈጣን ፕሮቶታይፕ በአንፃራዊነት አዲስ ቃል ነው ፡፡ ሆኖም በአጭር ጊዜ ውስጥ ተወዳጅነትን ለማግኘት ችሏል ፡፡ በዓለም ዙሪያ ያሉ ኢንዱስትሪዎች ፈጣን ፕሮቶታይፕን ለመጠቀም ወደ ዝንባሌ እየገቡ ናቸው ፡፡ ለነገሩ እንደ ዋጋ መቀነስ ፣ ከስህተት ነፃ ምርት ፣ ወዘተ ያሉ በርካታ ጥቅሞችን ይሰጣል ፡፡

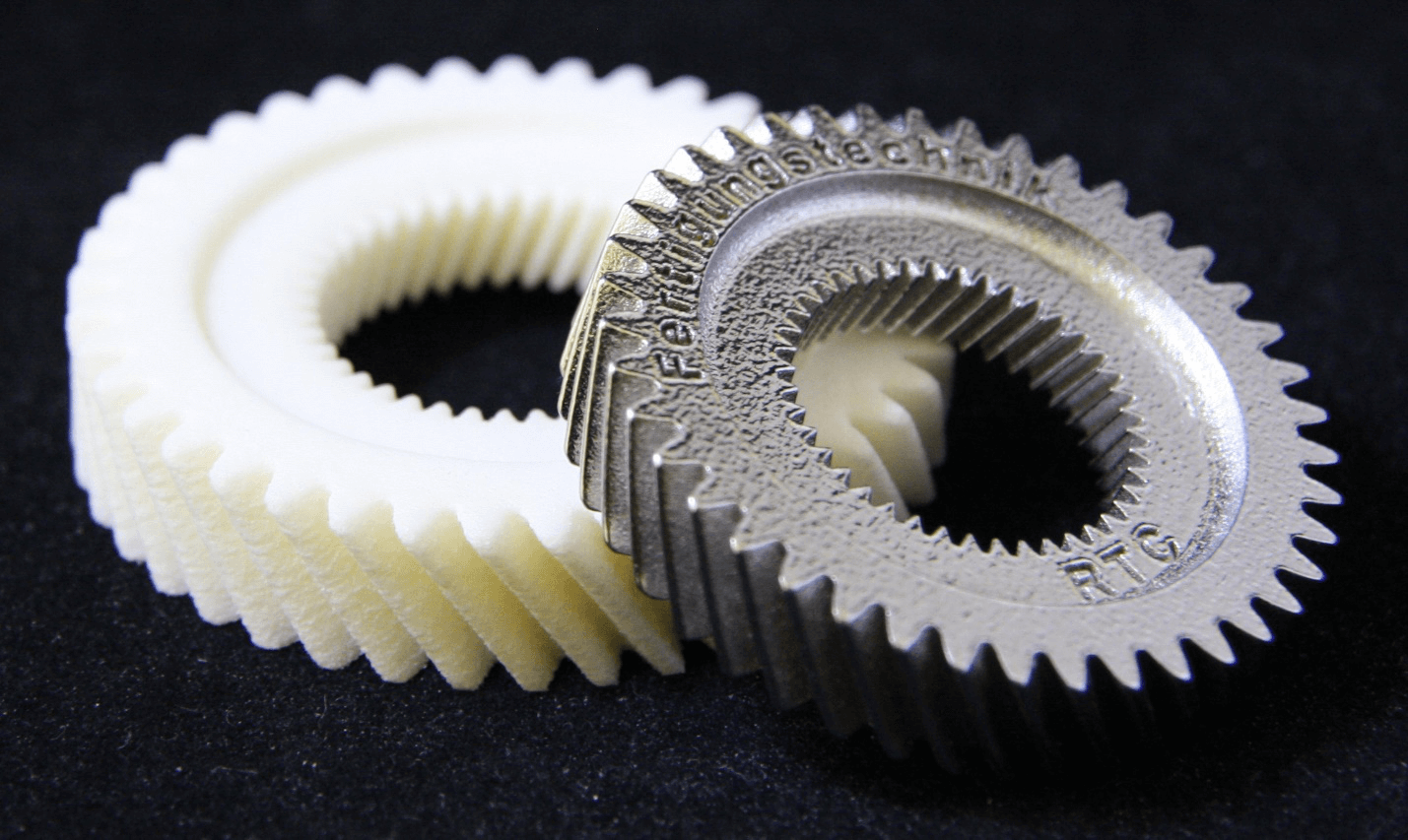

ዘዴው በርካታ የማኑፋክቸሪንግ ቴክኖሎጂዎችን ያጠቃልላል ፡፡ ከእነዚህ ቴክኖሎጂዎች ውስጥ በጣም የተለመዱት ተጨማሪዎች ማምረት ናቸው ፡፡ ሆኖም ፣ አምራቾች ወደ አርፒ (RP) የሚጠቀሙባቸው ሌሎች ቴክኖሎጅዎች አሉ ፣ መቅረጽ ፣ ማስወጣት ፣ መውሰድ እና ከፍተኛ ፍጥነት ያለው ማሽነሪ ፡፡

ስለዚህ ፣ በዚህ ብሎግ ልኡክ ጽሁፍ ስለ ፈጣን ፕሮቶታይፕ ፣ ስለ ዓይነቶቹ እና ስለ ጥቅሞቹ እንነጋገራለን ፡፡

ለፈጣን-ፕሮቶታይፕ መግቢያ

በሶፍትዌሩ መስክ ውስጥ ፕሮቶታይንግ የሚለውን ቃል ሰምተው ይሆናል ፡፡ ውጤታማ እና ቀልጣፋ በሆነ ሁኔታ ሶፍትዌርን ለመፍጠር ይጠቀማሉ ፡፡ ተመሳሳይ የፕሮቶታይፕ ደንብ በሌሎች መስኮችም ይሠራል ፡፡

ቀለል ባለ መልኩ ፈጣን ፕሮቶታይፕንግ ፕሮቶታይፕስ በብቃት እንደመፍጠር ልንገልፅ እንችላለን ፡፡ መሐንዲሶች የምርት አምሳያቸውን ትክክለኛነት ለመፈተሽ እነዚህን ቅድመ-እይታዎች ይጠቀማሉ ፡፡ በተጨማሪም ፣ የመጨረሻው ምርት እንዴት እንደሚታይ እና እንደሚሰራ ለማየት ችለዋል ፡፡

A more formal definition is: Prototype is a preliminary version of an end-product. It makes it possible to evaluate the design, analyze its working, and test its technology. This results in a product that has the specification that would work in the real-world system.

There is no denying the importance of prototypes in designing the product. In addition, it plays a vital role in the overall development cycle of the product. The good thing about rapid-prototyping is that you can use it at any stage of the product development cycle.

Moreover, you can use it for a certain component or a sub-component of the product. The versatility in terms of production makes RP an excellent choice. What more is that you can make as many changes to the prototype as you like.

The endless iterations are not expensive especially when you compare them with the rework you might have to do in case of design error with the entire product batch.

Rapid-Prototyping: Different Techniques

Below, we have listed different types of Rapid-prototyping.

Vat Photopolymerization or Stereolithography

Vat photopolymerization is an inexpensive, yet efficient technique. Being the first fruitful marketable 3D printing technique, it became very popular in a short time. The technique uses a photosensitive liquid to make the prototype. The ultra-violet light monitored by a computer solidifies this liquid layer by layer to achieve the respective results.

Selective Laser Sintering -- (SLS)

SLS is an effective technique for both plastic and metal prototyping. It uses a powder bed to create one layer of the prototype at one time. To sinter and heat the powder material, SLS uses a high-power laser. Although, it can manipulate two different materials, it lacks the robustness of the SLA.

The prototypes created using SLS are not steady. Furthermore, most products require secondary work to achieve the surface of a finished product.

Fused Deposition Modelling

Another inexpensive rapid-prototyping technique is fused deposition. You will find this technique part of many non-industrial 3D printers. The procedure requires a spool of thermoplastic filament. It melts the material inside the nozzle barrel of the printer.

Now, the computer deposition program lays down the melted material layer by layer in accordance with the requirements. Initially, the fused deposition modeling offered low-quality and weak products. However, technological advancement has improved the entire process.

It still is affordable, yet the quality of the prototype has improved tremendously.

Selective Laser Melting

If the prototype you require is complex and should be highly durable, the SLM prototyping technique is your best shot. Industries like automotive, medical, defense and aerospace frequently use SLM.

የአሰራር ሂደቱ ጥሩ የብረት ዱቄትን ይጠቀማል ፡፡ የዱቄት ሽፋኑን በደረጃው ይቀልጣል ፣ ስለሆነም ቀስ በቀስ የመጀመሪያ ደረጃውን ይገነባል። አምራቾችም ጠንካራ እና ጠንካራ አካላትን ለመገንባት ይህንን ዘዴ ይጠቀማሉ ፡፡ ኃይልን ለማቅለጥ በኤሌክትሮን ጨረር ወይም በከፍተኛ ኃይል የሚሰሩ ሌዘርዎችን ይጠቀማል ፡፡

ኮባልት ክሮም ውህዶች ፣ አልሙኒየሞች ፣ ታይትኒየም እና አይዝጌ ብረት የተለመዱ የተመረጡ የጨረር ማቅለጥ ቁሳቁሶች ናቸው ፡፡

ሉህ ላሜራ

እንደ ኤስ.ኤስ.ኤስ እና ኤስ.ኤስ.ኤል (SLS) እና እንደ SLM ሳይሆን ፣ የታሸገ እቃ ማምረቻ ግትርነትን ይጎድለዋል ፡፡ በልዩ ሁኔታ ቁጥጥር የሚደረግበት ሁኔታ አያስፈልግም ፡፡ በጣም አናሳ የሆነው ቴክኒክ በርካታ ላሜራዎችን ይጠቀማል ፡፡ እነዚህ ተከታታይ ላሚናኖች ሁል ጊዜ ቀጭኖች ናቸው ፡፡ ከዚያ የ CAD ዲዛይን ለማምረት እነዚህን የተደራረቡ ክምርዎች ለመቁረጥ የሌዘር ጨረሮችን ይጠቀማል ፡፡

ክፍሉን ለመገንባት እያንዳንዱ ሽፋን ከቀዳሚው አናት ላይ ተቀላቅሏል ፡፡ የሚፈለገው ቅርፅ እስኪሳካ ድረስ ሂደቱ ይቀጥላል ፡፡

የቢንደር ጄትንግ

Binder jetting offers the facility of printing several parts at the same time. It does offer mass production; however, the quality of the prototype is not very strong. The technique uses a powder bed. To bind the powder particles together, it sprays droplets of the liquid via nozzles.

These liquid droplets are micro-fine. This process is repeated for every layer of the part. Moreover, it is important to compact a layer using a roller, before starting with the next layer of the powder.

Doing this solidifies the entire process. To further enhance the robustness of the product, it is cured in an oven. This curing helps to burn off the binding agent. At the same time, it helps in powder fusing in just the right coherent parts.

ዲጂታል ብርሃን ማቀነባበሪያ

Digital light processing uses the same mechanism as that of the SLA. However, it does not require an extremely sophisticated method for the cure of polymerization of resins. It uses an orthodox light source to cure the resins.

Even though it is cheaper and faster in comparison to the SLA, the technique does require a post building curing. In addition, there is a need for support structures.

Prototype in Product Design

It is possible to category prototypes. However, this greatly depends upon the accuracy that is required by the consumer. In formal words, you can categorize prototypes based on fidelity.

- Fidelity Types

- Low Fidelity Prototype

These types of prototypes do not look like the final product. They may vary to a certain degree. The difference depends upon what the product designer wants to achieve from the prototype.

Low Fidelity

The low fidelity products are extremely simple. It is possible to produce them in a short period. The basic idea is to test the broader concepts, for instance, cardboard mock-ups or paper sketches.

High Fidelity

The high-fidelity products are extremely similar to that of the final product. They not only look like the final product but also offer most of its functionality.

Why Rapid Prototyping is Important?

For a company to stay afloat in the modern-day, fast-moving consumer market, it needs to be innovative. Not only this, but the company also needs up to come up with better, advance, and sophisticated products fast to ensure competitiveness.

የቴክኖሎጂ ፈጠራ እና ፈጣን የምርት ልማት ለኩባንያው ስኬት ወሳኝ ሚና የሚጫወት በመሆኑ ስለሆነም ፈጣን ፕሮቶታይሉ ለምርቱ የልማት ዑደት ወሳኝ አካል ይሆናል ፡፡

በፍጥነት ፕሮቶታይፕ በመጠቀም የሚከተሉትን ማሳካት ይቻላል ፡፡

- ፕሮቶታይፕንግ አዳዲስ ምርቶችን በብቃት ለመፍጠር ያስችለዋል ፡፡ መላውን የምርት ልማት ዑደት የማፋጠን አዝማሚያ አለው።

- ወደ ምርት ደረጃ ከመግባታቸው በፊት የምህንድስና ሀሳባቸው እንደሚሰራ ወይም እንደማይሰራ ለኢንጂነሮች ማወቅ ይቻላል ፡፡ በ RP አማካኝነት የምርት ንድፍዎን ሀሳብ በትክክል ማረጋገጥ ይችላሉ።

- እንዲሁም በንግድ ዓላማዎች እና በቴክኒካዊ መስፈርቶች ላይ የመጨረሻውን ደረጃ የምርት ማረጋገጫ ያቀርባል ፡፡

- በፕሮቶታይንግ አማካኝነት የመጨረሻ ተጠቃሚዎች ፣ ደንበኞች ፣ ደንበኞች አብረው የሚሰሩ ተጨባጭ ምርት ስለሚኖራቸው በእውነተኛ ጊዜ ግብረመልስ ሊሰጡ ይችላሉ ፡፡

ተይዞ መውሰድ

ፈጣን ፕሮቶታይፒንግ በሁሉም መንገድ የቴክኖሎጂ ፈጠራን ይረዳል ፡፡ ገንቢዎች እና መሐንዲሶች የምርት ሀሳቡን እንዲያረጋግጡ ያስችላቸዋል ፡፡ በተጨማሪም ፣ በምርት ዲዛይኑ ውስጥ ከማምረቻው ጊዜ በፊት በደንብ እንዲታይ ያደርግዎታል ፡፡

ጋር ፈጣን-በፕሮቶታይፕ , አንተ በእርግጥ ተጨባጭ ነገር ወደ የእርስዎ ሀሳብ ሊለውጡት ይችላሉ. ሀሳቡን በበለጠ እምነት ለባለሀብቶች ማቅረብ እና እነሱን የማረፍ እድልን ከፍ ማድረግ ይችላሉ ፡፡