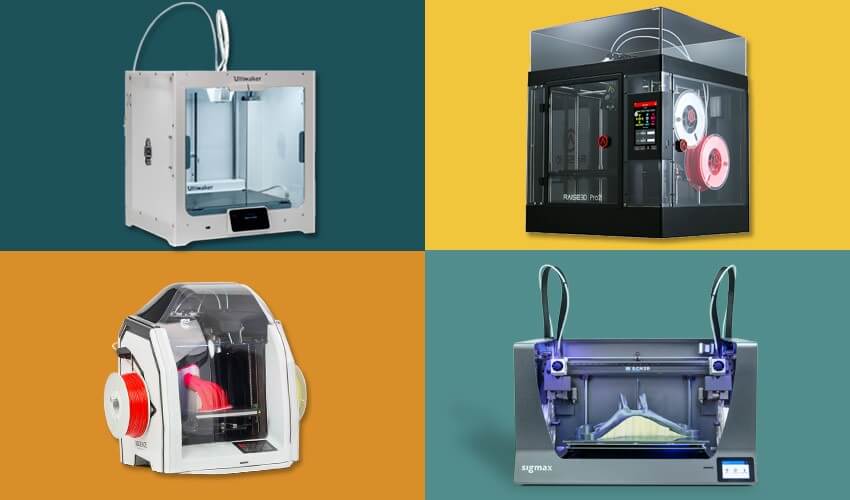

Which is the best extrude with two color 3D Printer in 2020?

2020-12-26Two-color printing made easy

To choose extrude with two colors 3D printer that is right for you, you first need to decide what you will print. This will determine which 3D printer model is best for you for these purposes.

It is important to understand that desktop 3D printer is not a machine for production of mass production of products. It is a tool for creating models, prototypes, design or printing small batches of small parts.

A 3D printer cannot completely replace a thermoplastic machine, silicone molding or a CNC milling machine. But at the same time it can become an indispensable tool for creating a high-quality prototype or demonstration model. A 3D printer is a great hobby that can even generate income for you.

- If you already know what you will be printing, you need to determine which plastic is best for printing the models you need.

Choosing a extrude with two colors 3D printer

The situation is more complicated with those who do not know what exactly will be printed or with those who want to experiment with different materials and models. But more on that below.

Most modern models of 3D printers already have many functions. Such as Wi-Fi, Ethernet, a color displays with a touchscreen, a webcam for remote control of the printing process. It is partial or fully automatic platform calibration and others.

These extrude with two colors features can be very useful, but it is important to understand that their presence or absence does not directly affect print quality. Quality primarily depends on the design of the printer in general. And the extruder in particular, as well as many other mechanical and electronic components.

Two color plastic extrusion

At the moment, all plastics can be conditionally divided into 2 groups. These are ABS plastics, which include, in addition to ABS itself, Nylon, PC, HIPS, PC-ABS and others. PLA plastics include PVA, PET, PETG, Wood, Flex, TPE, TPU and others.

The decisive factor for choosing a printer may be the plastic you plan to print with. Because these two groups of plastics have different properties and, above all, different printing nuances.

A completely enclosed working chamber and a heated table are essential for printing with ABS plastic. As, for example, in the FlashForge Dreamer or UP BOX + 3D printer model. With these printers, you have the ability not only to set the site temperature. But also to maintain a high temperature throughout the entire working chamber, up to 90 ℃. Under these conditions, the risk of extrude with two colors model delamination during printing reduces and quality of finished model will be higher.

What is PLA two color printing?

A heated pad is optional for PLA printing. But good airflow of the model during printing is very important. Printing with PLA plastics is in many cases much easier for a beginner. An example of such printers is the MakerBot Replicator + or the budget Chinese models Wanhao Duplicator i3.

Choosing a 3D printer

An important characteristic of a 3D printer is the presence or absence of a heated table. Almost all 3D printer manufacturers claim that their products can be printed with all kinds of materials. But in practice this is not at all the case.

If printer does not have a heated bed, then printing any ABS plastics on it will be very difficult. Especially when you need to print large models.

Also, when choosing plastic for your tasks, you need to pay attention to the post-processing of models. Different materials have different properties not only during printing, but also in the form of finished products. For example, ABS plastic is easy to polish or gloss in an acetone bath, and PLA is good suitable for priming and subsequent painting.

ABS product after extrude with two colors bath

Choosing a 3D printer

If you want to print with different types of materials, then you need a versatile extrude with two colors 3D printer that can handle any task. Such models also exist, for example Raise3D N1 Dual or FlashForge Creator Pro. The printer comes with a fully enclosed chamber, which is essential for ABS printing, but with a few easy strokes, you can transform it into a fully open state, perfect for PLA.

Printing with special plastic is a double experiment. For most 3D printers, manufacturers do not provide information on the possibility of printing with one or another type of experimental plastic.

Pay attention to the melting point of the plastic you are going to print with. It is also important to understand at what speed you need to print, taking into account the flow rate of this type of plastic.

It is also worth paying attention to such parameters as the size of the working chamber and the minimum layer thickness.

What is the price factor of two color extrude printer?

The larger the size of the working chamber, the higher the price, so it is worth deciding whether you need a large sized camera or whether a medium or small size camera is suitable for your needs. You also need to understand that printing large models will take a very long time, in some cases up to two days.

It may be better to print the model in chunks and glue it from the printed chunks of medium size.

Before that, I have made and tested a double swinging extruder. I also used the 'Y' extruder earlier. As you know, each of these extruders has its own pros and cons. As a rule, extrude with two colors extruders have a large consumption of plastic and time, and the "rocker" - the loss of printed volume.

Then I thought about combining these two types into one, or rather their positive aspects. This is how the revolver extruder was born.

The Uniqueness of extrude with two colors printer

Extrude with two colors uniqueness is that it allows you to print with two plastics from different nozzles, but the nozzles are positioned after switching at one point and the printed volume is not lost. Also, the unused nozzle rises, which eliminates the touching of the model.

In this type of extruder, it turned out to achieve better repeatability compared to the same "rocker". It is easier to service it, for its seemingly large dimensions, it actually takes up less space. The locking system invented by me excludes false switching, everything is securely locked.

Conclusion

This prototype still lacks shutters to cover an unused nozzle, but it is quite suitable for printing in this state. There are still a few mechanic modifications to come and more printing tests.