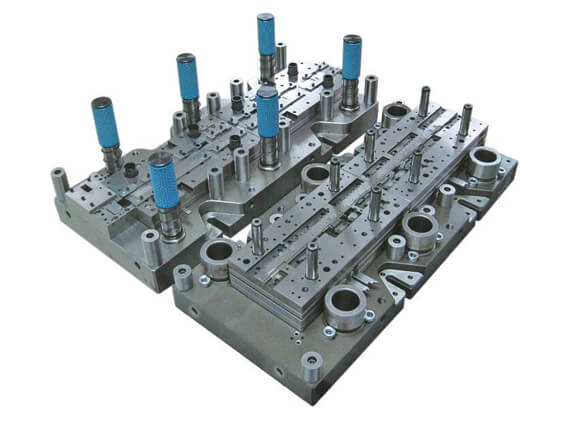

Fabricant de moules de précision pour matrices d'estampage composites

- Longue durée de vie

- Surface lisse, sans bavures

- Processus de fabrication de précision

- Selon le dessin ou l'échantillon du client

- Service après-vente professionnel

When you need to stamping die mold with high precision, please ask us for help. Essai offers you high quality stamping die molds in a variety of industries.

There are many forms of stamping dies. And according to the nature of the workpiece, the mold structure and mold material are classified.

According to the nature of the process:

1. Punching dies along the closed or open contour line to make the material separate mold. Such as blanking die, punching dies, cutting die, cutting die, trimming die, cutting die, etc.

2. Bending die makes the sheet blank or other blanks deform along a straight line (bending line), so as to obtain a certain angle and shape of the workpiece mold.

3. The drawing die is a die that makes the blank of the sheet material into an open hollow piece, or further changes the shape and size of the hollow piece.

4. The forming mold is a mold that directly shapes the rough or semi-finished workpiece according to the shape of the convex and concave molds, and the material itself only produces local plastic deformation. Such as bulging die, shrinking die, expanding die, undulating forming die, flanging dies.

5. The riveting die is to use external force to connect or overlap the parts in a certain order and manner, and then form a whole according to the degree of process combination.

Process Combination

1. Single-process die In one stroke of the press, only one die of the stamping process is completed.

2. There is only one station for the compound mold. In one stroke of the press, two or more stamping processes are completed at the same station at the same time.

3. The progressive die (also called a continuous die) has two or more stations in the feed direction of the blank and completes two or two passes at different stations in one stroke of the press The mold for the above stamping process.

4. The transfer mold combines the characteristics of single-process mold and progressive mold. Using the robot transfer system to achieve the rapid transfer of products within the mold can greatly improve the production efficiency of the product, reduce the production cost of the product, save the material cost, and have stable quality reliability.

According to the classification of product processing methods, according to different product processing methods, the molds can be divided into five categories: punching and shearing molds, bending molds, drawing molds, forming molds and compression molds.

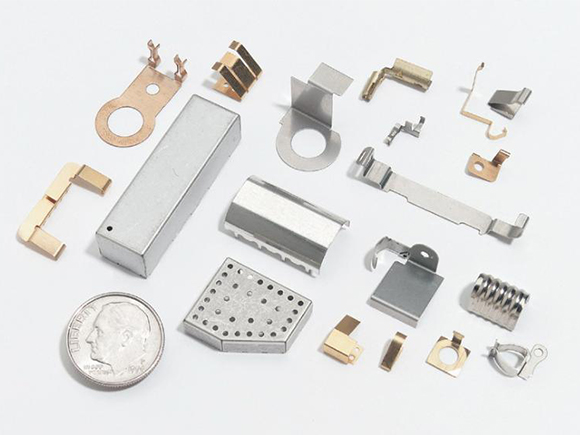

Stamping Dies Applicable Materials

1. The deep drawing process depends on the balance of metal ductility and compression resistance. Suitable metals are steel, copper, zinc, aluminum alloy, and other metals that are easy to tear and wrinkle during the deep drawing process.

2. Because the ductility of the metal directly affects the production efficiency and quality of deep drawing, it is generally processed with metal flakes as raw materials.

Stamping Dies Design Considerations

1. The internal diameter of the cross-section of the parts formed by deep-drawing should be controlled between 5mm-500mm (0.2-16.69in).

2. The preliminary length of deep drawing is 5 times the inner diameter of the section.

3. The longer the longitudinal length of the part, the thicker the metal sheet, otherwise surface tearing will occur during processing. Because during the stretching process, the thickness of the metal sheet will gradually change.

Generally, times drawing, the depth of single-stroke die drawing can be drawn once, the calculation of the drawing coefficient of general drawing parts is the diameter after stretching / the diameter before stretching, that is m1 = d1 / D0. The ratio is 0.48 ~ 0.5, which is easy to pull if it is smaller. The last stretch ratio is 0.8 ~ 0.82.

- Longue durée de vie

- Surface lisse, sans bavures

- Processus de fabrication de précision

- Selon le dessin ou l'échantillon du client

- Service après-vente professionnel

CAS SIMILAIRE

Fournir un support matériel technique aux entreprises de divers secteurs.

Vous n'en savez pas assez?

Bienvenue à nous contacter et à démarrer votre entreprise maintenant!

Bureau : No.72-6, huanguan South Road, Longhua New District Shenzhen, 518110 Chine

Usine : No.333 Xiangmang West Road Qingxi Town, Dongguang, Chine