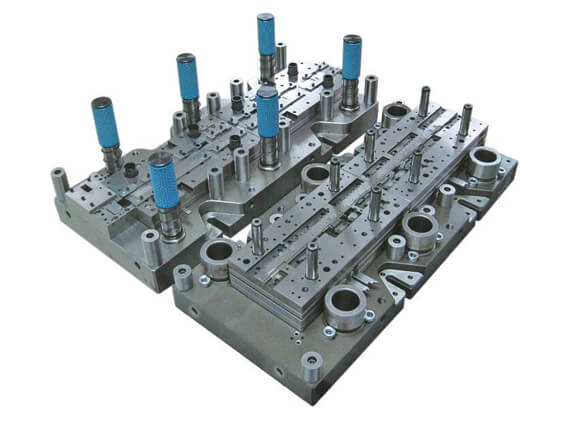

Produttore di stampi di precisione per stampi compositi

- Lunga vita

- Superficie liscia, senza sbavature

- Processo di fabbricazione di precisione

- Secondo il disegno o il campione del cliente

- Servizio post-vendita professionale

When you need to stamping die mold with high precision, please ask us for help. Essai offers you high quality stamping die molds in a variety of industries.

Esistono molte forme di stampi per stampaggio. E in base alla natura del pezzo in lavorazione, la struttura dello stampo e il materiale dello stampo vengono classificati.

Secondo la natura del processo:

1. Punzonatura muore lungo la linea di contorno chiusa o aperta per rendere il materiale stampo separato. Come la tranciatura, la punzonatura, la fustellatura, la fustellatura, la rifilatura, la fustellatura, ecc.

2. Lo stampo di piegatura fa deformare il foglio o altri semilavorati lungo una linea retta (linea di piegatura), in modo da ottenere un certo angolo e forma dello stampo del pezzo.

3. The drawing die is a die that makes the blank of the sheet material into an open hollow piece, or further changes the shape and size of the hollow piece.

4. Lo stampo di formatura è uno stampo che forma direttamente il pezzo grezzo o semilavorato in base alla forma degli stampi convessi e concavi, e il materiale stesso produce solo deformazione plastica locale. Come lo stampo sporgente, lo stampo restringente, lo stampo espandibile, lo stampo ondulato di formatura, gli stampi flangiati.

5. The riveting die is to use external force to connect or overlap the parts in a certain order and manner, and then form a whole according to the degree of process combination.

Process Combination

1. Single-process die In one stroke of the press, only one die of the stamping process is completed.

2. There is only one station for the compound mold. In one stroke of the press, two or more stamping processes are completed at the same station at the same time.

3. The progressive die (also called a continuous die) has two or more stations in the feed direction of the blank and completes two or two passes at different stations in one stroke of the press The mold for the above stamping process.

4. The transfer mold combines the characteristics of single-process mold and progressive mold. Using the robot transfer system to achieve the rapid transfer of products within the mold can greatly improve the production efficiency of the product, reduce the production cost of the product, save the material cost, and have stable quality reliability.

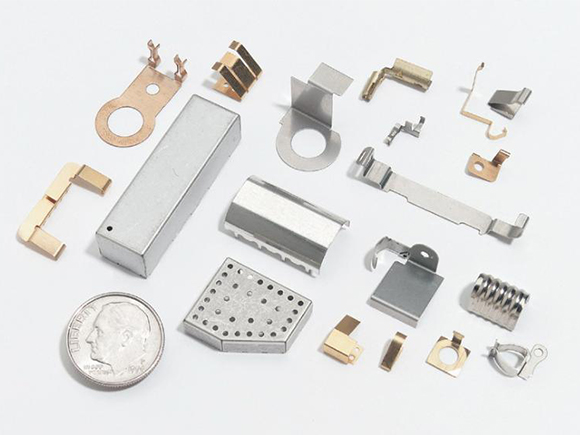

According to the classification of product processing methods, according to different product processing methods, the molds can be divided into five categories: punching and shearing molds, bending molds, drawing molds, forming molds and compression molds.

Stamping Dies Applicable Materials

1. The deep drawing process depends on the balance of metal ductility and compression resistance. Suitable metals are steel, copper, zinc, aluminum alloy, and other metals that are easy to tear and wrinkle during the deep drawing process.

2. Because the ductility of the metal directly affects the production efficiency and quality of deep drawing, it is generally processed with metal flakes as raw materials.

Stamping Dies Design Considerations

1. The internal diameter of the cross-section of the parts formed by deep-drawing should be controlled between 5mm-500mm (0.2-16.69in).

2. The preliminary length of deep drawing is 5 times the inner diameter of the section.

3. The longer the longitudinal length of the part, the thicker the metal sheet, otherwise surface tearing will occur during processing. Because during the stretching process, the thickness of the metal sheet will gradually change.

Generally, times drawing, the depth of single-stroke die drawing can be drawn once, the calculation of the drawing coefficient of general drawing parts is the diameter after stretching / the diameter before stretching, that is m1 = d1 / D0. The ratio is 0.48 ~ 0.5, which is easy to pull if it is smaller. The last stretch ratio is 0.8 ~ 0.82.

- Lunga vita

- Superficie liscia, senza sbavature

- Processo di fabbricazione di precisione

- Secondo il disegno o il campione del cliente

- Servizio post-vendita professionale

CASO SIMILE

Fornire supporto tecnico hardware per aziende in vari settori.

Non ne sai abbastanza?

Non esitare a contattarci e inizia subito la tua attività!

Ufficio : No.72-6, Huanguan South Road, Longhua New District Shenzhen, 518110 Cina

Fabbrica : No.333 Xiangmang West Road Qingxi Town, Dongguang, Cina