Cos'è lo stampaggio metalli freddo e caldo? Come realizzare lo stampaggio di lamiere?

2020-07-21Una guida pratica per comprendere la pressa per stampaggio metalli

Il tema del metal è rimasto popolare in ogni epoca. È particolarmente famoso in relazione alla tecnologia moderna. In realtà, però, lo stampaggio dei metalli è un mestiere antico che nei secoli è diventato una tecnica avanzata.

Cos'è lo stampaggio di metalli?

Lo stampaggio dei metalli is a controlled deformation process in which the body changes its shape under the influence of excessive pressure. Thanks to such processing, metal products are given the most diverse forms that they need to fulfill their functional duties.

Stamping gives in to parts of small thickness, since bending thick products is very problematic.

How metal stamping is carried out?

Metal stamping allows you to quickly and accurately shape the original sheet material into a finished product.

This process consists in the deformation of the metal under the action of directional pressure. In this case, the material changes its shape, while maintaining the initial thickness of the sheet.

The main types of metal stamping

This method of processing is used in small, medium and large volumes in industries.

Stamping of metal products is used in almost all industries. Moreover, it allows you to create any kind of detail. This technology has a very long history and is now actively developing.

New methods are constantly emerging that use forces of different origins other than gravity. Similarly, deformation occurs under the influence of:

- hydraulic pressure

- electric current

- Magnetic field, etc.

Next, we will consider issues related to the principle of operation of:

- stampaggio dei metalli

- types and

- methods of metal deformation

- The use of products created in this way in various industries.

What is sheet metal deformation?

Deformation of sheet metal can be carried out under the influence of high pressure. Based on this, all types of stamping can be divided into two large groups:

- cold;

- hot

Generally, both types have advantages and disadvantages that delimit the scope of their use. Cold stamping is carried out at a temperature below the melting point of the metal.

Furthermore, this avoids shrinkage during cooling. But it imposes restrictions on the shape of the final product. This method creates parts without a large number of embossed elements, for example, parts of a car body.

The main requirements for the material used during cold stampaggio dei metalli are high ductility. In addition, the method is suitable for:

- low-carbon and alloy steels

- copper

- Brass

- aluminum and magnesium alloys, and

The following is required for metal stamping:

- A soft pad, a metal foil and embossing tool.

- If you want to try out the technique first, you can use a simple embossing pen and a teaspoon as a tool.

- Se ti piace questo hobby, dovresti procurarti gli strumenti giusti. È molto più facile ottenere risultati molto, molto migliori.

- Gli speciali stampaggio dei metalli sembrano un po '"antiquati". Ma anche molto stabili - ed è esattamente quello che sono! Servono al loro scopo meglio di alcuni nuovi strumenti. Perché sono stabili e si adattano bene alla mano.

Perché lo stampaggio dei metalli?

Lo stampaggio dei metalli è un processo di produzione importante, a seconda di cosa lo stampaggio richiede forma e funzione. I vantaggi sono:

- alto tasso di produzione

- consistenza e

- A basso costo.

Stampaggio metalli è applicata in molti settori. Ad esempio:

- Settore automobilistico

- industria pesante

- industrie elettroniche

- componenti elettronici

- Accessori hardware

- Accessori per veicoli.

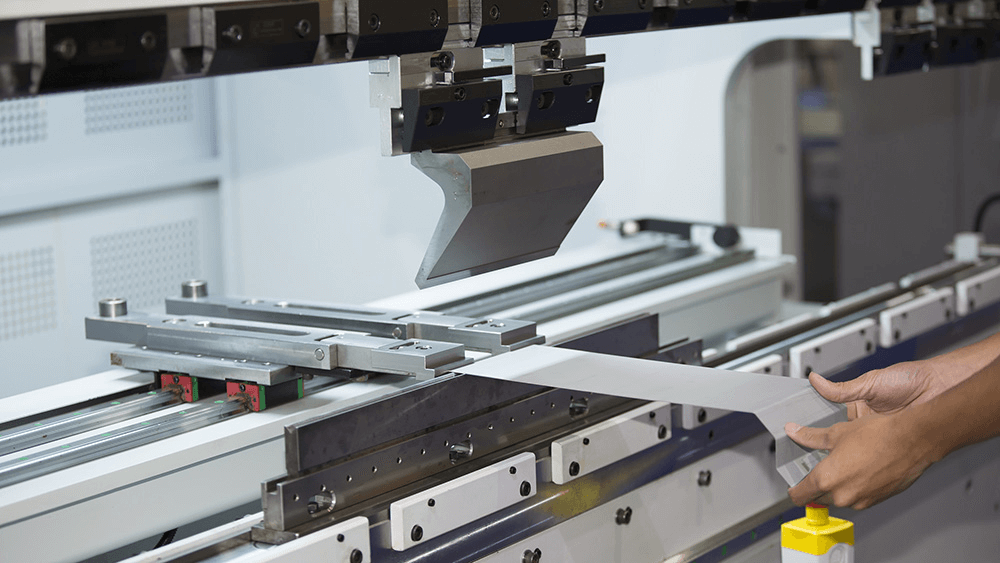

Stampaggio La tecnologia di stampaggio è una tecnologia per formare una forma desiderata combinando le tecnologie. Ad esempio:

- Flessione

- Disegno

- punzonatura e

- Taglio di materiali in lamiera.

Ha il vantaggio di poter realizzare un gran numero di prodotti a basso costo. È una delle principali tecnologie per la produzione di parti metalliche.

Principali martelli meccanici utilizzati nella forgiatura

Le moderne macchine per forgiatura includono principalmente martelli meccanici e presse.

Innanzitutto, ci sono due tipi principali di martelli meccanici utilizzati nella forgiatura:

- martelli d'aria

- e martelli a molla

Cos'è lo stampaggio idraulico dei metalli?

Una pressa idraulica è una pressa che utilizza la pressione di un cilindro in cui viene alimentata acqua o olio per eseguire la lavorazione. Il carico e la velocità possono essere controllati regolando la pressione idraulica inviata al cilindro.

The potential of cold sheet metal stamping

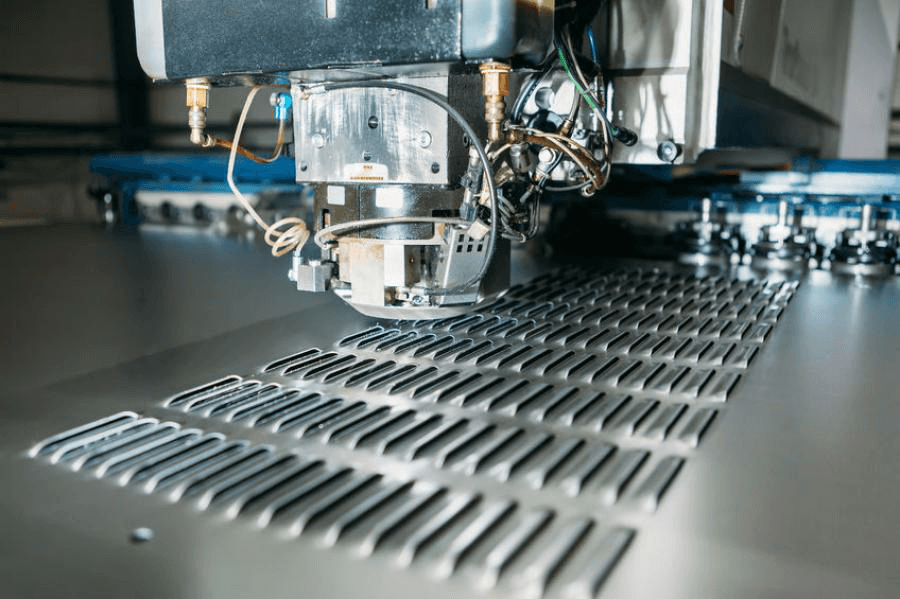

The sheet stampaggio dei metalli and forming is a production process that allows you to create objects and metal products starting from a lamina. It is compressed and molded into different shapes and sizes depending on the type of tool.

The sheet is applied in many sectors, from furniture to electronics, from objects to heating, from the food to the industrial sector.

The stamping of the sheet allows producing high quality objects at low costs. Even when the shapes and characteristics are very elaborate and rich in details.

This is because the machinery used in production and the production processes are highly sophisticated and cutting edge in every respect.

The fastest and most efficient sheet metal pressing technique is the cold one. Let's look at how it works.

What is cold stamping of sheet metal?

The cold sheet is the most convenient and rapid type of industrial molding. Because it is operated at ambient temperature, without requiring the heating of machinery and metal plates before machining.

Generally, it greatly reduces the waste of energy, economic and temporal. This is why many companies use it for sheet metal stamping in Turin and throughout Italy.

Conclusion on metal stamping

It's used for a very long time. Since it comes from the forging of metals - a process that develops together with humanity. without which it is impossible to imagine the creation of tools, construction tools and weapons.

Modern methods of manufacturing parts require not only high precision, but also material savings. While cutting metal, a very large part of it goes into chips maximum rationality. It consumes material, giving it a shape that practically does not need further processing.

Although the presses used for stampaggio dei metalli are constantly evolving, increasing power and productivity. Their technical characteristics sometimes do not allow the creation of parts of very large sizes.

In this case, alternative methods come to the rescue. Such methods use hydraulic, explosive and electromagnetic forces.

The introduction of these methods into production allows you:

- to reduce the consumption of materials

- increase the accuracy and

- reliability of products and

- speed up the production processes.