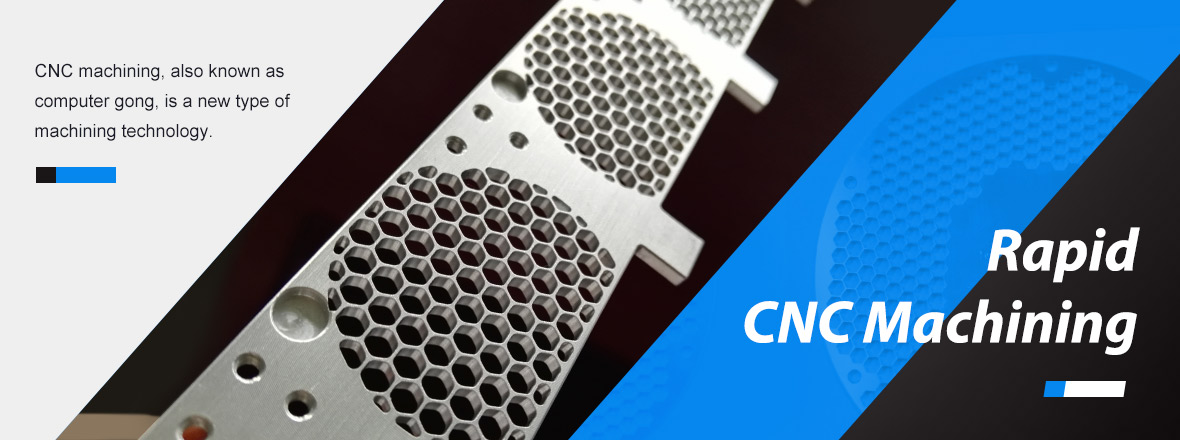

Rapid CNC Machining

Rapida lavorazione CNC

Essai specialize in rapid prototyping, sheet metal and low volume production of custom parts. Our international team of engineers and technicians use advanced equipment and techniques like 3D metal printing, multi-axis CNC machining and plastic injection molding, to turn your designs into reality quickly, accurately and at a great price.

We use the latest software programs, advanced CNC machine tools, modern measuring equipment and skilled technicians, competitive quotations, fast delivery, and excellent quality. Essai has been widely recognized by customers worldwide.

Capacità produttiva:

Essai can process workpieces ranging in size from a few millimeters to complex components such as automotive dashboards. There are always a variety of stocks of plastics and metal blanks, such as Aluminum, stainless steel, carbon steel, PC, ABS, POM ... and so on, to meet many customer needs. If needed, we can also quickly purchase more exotic materials for special projects. Most Essai prototypes are produced by CNC, so they ensure accuracy equal to or better than injection molding and allow customers to bring their own materials to make their prototypes.

Allo stesso tempo, Essai può anche fornire ai clienti i relativi servizi di post-trattamento e trattamento delle superfici, come spolveratura e ossidazione. Le nostre capacità di lavorazione CNC di metalli possono produrre vari tipi di parti con dimensioni diverse per molti settori, tra cui automobilistico, aerospaziale, navale, edile, scientifico, medico, ecc. Con il software CAD / CAM più recente e l'esperienza nella lavorazione della maggior parte dei metalli, siamo in grado per produrre pezzi di alta precisione in piccole e grandi quantità. Possiamo anche fornire servizi di lucidatura tra cui lucidatura, cromatura, doratura, verniciatura a polvere a spruzzo, immersione a caldo e anodizzazione.

Before starting to manufacture any components, our dedicated account managers and project engineers will discuss the required performance of prototype parts with customers to ensure that only the most suitable materials, processes, production, processing, and transportation methods are used; if your product quantity is not large, The time is short, and high-end requirements, please choose this processing technology-CNC Machining, choose us Essai, we will give you professional services from your inquiry.

Vantaggi della lavorazione CNC:

- Significantly reduce the number of tooling, complex parts do not require complex tooling. If you want to change the shape and size of the part. You only need to modify the part processing program. This is suitable for the development and modification of new products.

- The processing quality is stable, the processing accuracy is high, and the repeatability is high. It meets the processing requirements of the aircraft.

- In the case of multi-variety and small batch production, the production efficiency is high. They can reduce the time for production preparation, machine tool adjustment and process inspection. And reduce the cutting time due to the use of the optimal cutting amount.

- Multi-coordinate linkage is possible. It can process complex profiles that are difficult to process by conventional methods. And can even process some unobservable processing parts.

- When machining parts change, generally only need to change the NC program, which can save production preparation time.

- La macchina utensile stessa ha un'elevata precisione e rigidità. Può scegliere un volume di lavorazione favorevole e un'elevata produttività (generalmente da 3 a 5 volte quella delle macchine utensili ordinarie).

- Un alto grado di automazione della macchina utensile può ridurre l'intensità del lavoro.

Svantaggi della lavorazione CNC:

- L'attrezzatura della macchina utensile è costosa e richiede un alto livello di personale di manutenzione.

- Ma il suo percorso di elaborazione non è facile da controllare e non è intuitivo come le normali macchine utensili.

- Presenta requisiti più elevati per la qualità degli operatori e requisiti tecnici più elevati per il personale di manutenzione.

I nostri servizi:

1) macchina CNC:

CNC a tre assi

CNC a quattro assi

CNC a cinque assi

Girando il CNC

Taglio laser

Lamiera

2) Prototipazione rapida: stampa 3D / SLS / SLA / Casting a vuoto

3) Compressione del silicio

4) produzione e assemblaggio a basso volume;

5) sheet metal part / stamping

Trattamenti superficiali:

Lucidare, dipingere, anodizzazione, elettroplazione, sabbiatura, serigrafia, scultura laser

Abbiamo servito l'industria:

Automotive, elettrodomestici, areospazia, elettronico di consumo, medico, difesa, giocattolo, ect.

Materiali:

1) Plastica - ABS, PMMA, PC, PP, PE, POM ECT.

2) Metal - alluminio, acciaio inossidabile, ottone, zinco ect.

3) altri - gomma, silicio, ect.

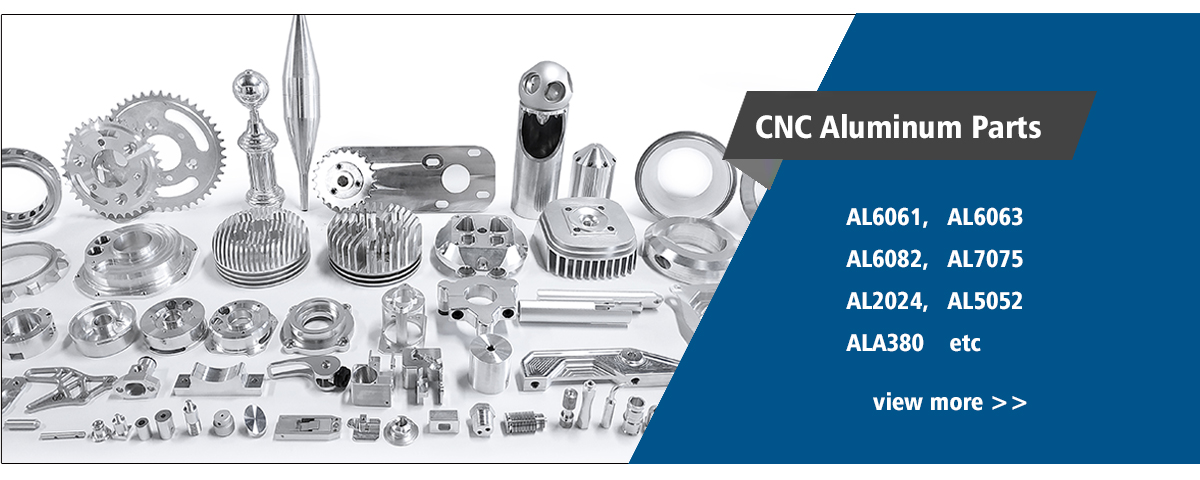

You can use all kinds of matel and plastic raw material, usually we use as below:

- Carbon steel / cold rolled sheet / hot rolled sheet / spcc.

- Stainless steel (201, 304, 316).

- Aluminium steel (5052, 6061, 7075).

- Brass / plactic ABS, PMMA, PC, PP, PE, POM / copper, etc.

Rapid CNC Machining Capabilities as follows: |

||

| Applications | Machine components | Medica devices |

| Security components | Valve devices | |

| Consumer components | Electronic housings | |

| Furniture components | Motor housings | |

| Smart lock components | Fittings / Contectings | |

| Lighting components | Furniture components | |

| Industry field | Medical | Aerospaziale |

| Security &Protection | Industrial | |

| Consumer | Packaging | |

| LED Lighting | Architectural | |

| Electronic | Household appliances | |

| Furniture | Office appliances | |

| Telecom | Military | |

| Agricultural | Automobile | |

| Production Volume | Prototype | Low Volume |

| Small quantity | Mass production | |

| Metal material | Alluminio | Carbon Steel |

| Bronze | Acciaio inossidabile | |

| Rame | Alloy Steels | |

| Brass | Ferro | |

| Plastic material | ABS | PVC |

| PP | PE | |

| PC | PBT | |

| POM | PEEK | |

| PVC | PSU | |

| PMMA | Nylon | |

| Part Surface | Mirror Polish | Anodizing |

| Plated | Passivation | |

| Painting | Electrophoretic coating | |

| Powder coating | Non- stick debron coating | |

| Industry standard | ISO 9001-2008 | TS16949 |

| Attrezzature | 5X 400X400mm high speed CNC / FANUC | |

| 2X 500X500MM high speed CNC / MORI SEIKI, | ||

| 1X 600x600MM high speed CNC/MAKINO | ||

| 20X 500X500mm high speed CNC/ Taiwan TAIKAN | ||

| 5X 600X600mm high speed CNC /Taiwan TAIKAN | ||

| 3X 800X800mm high speed CNC /Taiwan TAIKAN | ||

| Advantages | Shorter delivery time | Professional team |

| Competitive price | Good communication | |

| Tight tolerance | Good quality control | |

| File format | 2D format | 3D format |

| DWG | STEP | |

| IGES | ||

| DXF | X_T | |

| Packaging | Bubble | K-K carton / wood case |

| PE Foam | woodex /Plastic pallet | |

| Lead time | Normally 2-4 weeks | |

| But some of them depend on the quantites request. | ||

| Shipping | By air | |

| By express (DHL,UPS, FedEX) | ||

| By sea | ||

Benvenuto per iniziare subito la tua attività!

Contattaci