研削および溶接プロセス中の材料に対する熱の物理的影響

2020-10-26研削および溶接プロセスとそれらが材料の物理的特性に及ぼす影響。

The 粉砕および溶接プロセスは 、通常、材料表面を強化し、2つの材料を接合するために行われます。 金属は通常、研削と溶接のプロセスを受けます。 しかし、他の資料もあります。 セラミックやプラスチックなど。

Since metals are good conductors of heat, they sustain some physical effects due to these processes because of the high temperature involved. This high temperature not only acts as an additional load on the materials but also alters the mechanical properties of the workpiece.

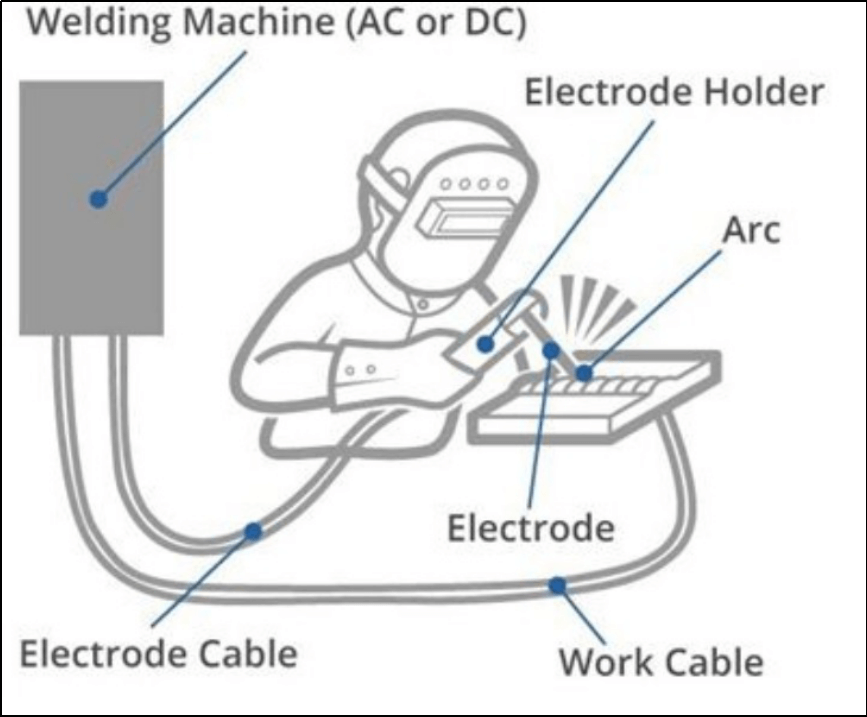

Welding is a high-temperature process that joins similar metals by fusion. While a workpiece undergoes grinding to smoothen its surface. The heat source in a grinding process is friction. The prolonged contact between the grinding wheel and the surface gives rise to this friction.

Intro to Grind and Welding Process

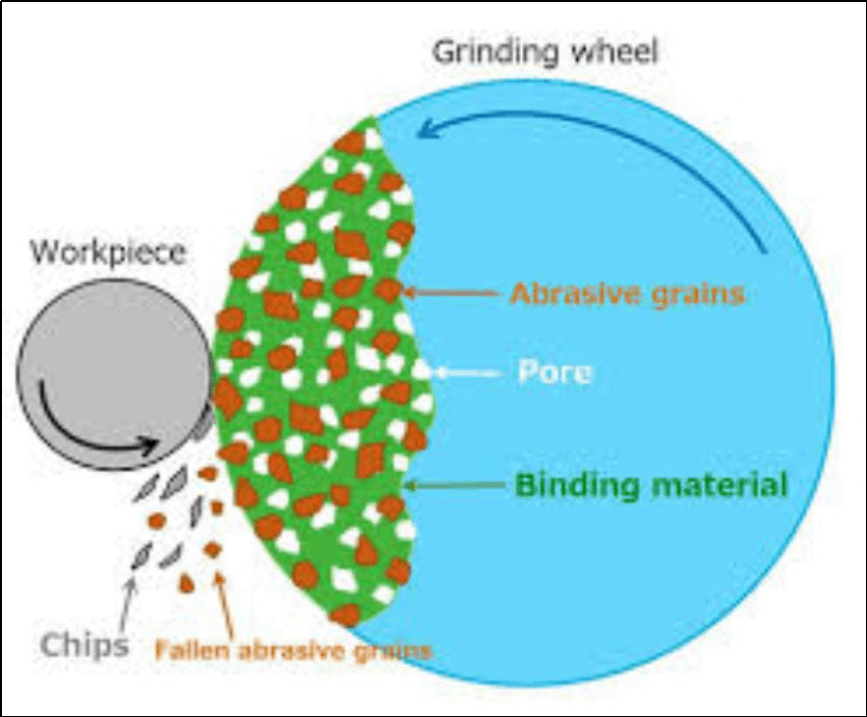

Grinding is classified as an abrasive machining process. A machining process is any process that removes a certain part of the raw material using cutting tools. Since small, abrasive particles perform cutting in this process. Therefore, it is called an abrasive machining process.

A workpiece requiring a smooth surface finish undergoes grinding. Usually, metals and ceramics go through this process.

In the case of grinding, the grinding wheel carries small abrasive particles. This grinding wheel rotates through an electrical motor. When the rotating grinding wheel comes in contact with the workpiece surface, it removes small parts of the surface and gives the workpiece a smoother finish.

The constant contact between the surface and grinding wheel gives rise to immense friction. This friction leads to the generation of heat which contributes to an increase in the temperature of both surfaces. This temperature rise often softens the workpiece and makes grinding easier.

The Welding Process:

Welding is a process that joins two similar materials together by fusion. It is an extreme-temperature-process that melts the two parent materials from the junction point. This melted portion of the parent materials allows them to fuse. Cooling to ambient temperature forms a strong joint between the two parent materials. This joint is sometimes stronger than the parent materials.

The most common materials involved in the welding process are Iron and Steel. Though plastics can also be joined by welding. Acetylene reacts with oxygen and produces a welding flame. The temperature of this flame could be as high as 6000˚C-8000 ˚C and beyond.

Physical Effects of Grind and Welding Process

The grind and welding process is a high abrasion, high-temperature processes. Thus, they cause the material to sustain some physical effects.

Tensile Residual Stress

Residual stress is the stress that resides in the material after the stress source has been removed. The grind and welding process leave behind significant tensile residual stress. This tensile residual stress can be harmful because it can lead to fatigue and structural damage.

Physical Effects of Grinding process.

The grinding process generates high heat in the grinding zone because it is high friction. This heat causes the temperature to increase in the zone. This increase in temperature affects the physical properties of the materials.

The material, grinding depth, and speed of grinding determine the temperature the surface reaches during the process. Hence, the temperature of the workpiece may reach up to 900 ˚C-1000 ˚C during the process.

Formation of chips

The excess material removed during grinding could accumulate on the surface of the workpiece in the form of chips. This could affect the working efficiency of the grinder and undermine the results of the process. This is why grinding operation requires a lubricant. The main purpose of this is to capture the small particles that the grinding wheel removes from the surface. And to keep them from accumulating on the surface.

Damaged Surface Integrity

Surface integrity is the condition of the surface after it has undergone a mechanical process. Researches show that the grinding process leads to the formation of a layer of fragmented pieces on the workpiece which reduces the surface integrity of the piece.

Loss of Magnetism

Metals such as Iron are magnetic. Magnets tend to lose a percentage of their magnetism with every degree rise in temperature. This loss of magnetism may be reversible, irreversible, or permanent.

The temperature reached during the grinding process is very high in the grinding zone. If this process continues without a coolant, the magnetic material may end up losing its magnetism reversibly, irreversibly, or permanently depending upon the temperature.

Physical Effects of Welding Process

Welding being a high-temperature fusion process exposes the workpiece to extremely high temperatures. This heat is distributed in the vicinity of the welded joint.

Exposure to extreme temperature cause Heat-Affected-Zones (HAZs) to form near the welded joints. These zones are classified as part of the parent material that did not undergo melting yet sustained changes in their mechanical properties due to their proximity to the high-temperature welding zone.

Phase Transformation

Since welding involves melting and then cooling of the metal, the metal undergoes a structural change after first melting at high temperature and then cooling down to the ambient temperature. This change in the structure of the metal is called phase transformation.

Phase transformation not only changes the structure of metal but also alters its mechanical properties such as tensile strength, hardness, and ductility, etc.

Reduced Corrosion Resistance

鋼の熱影響部(HAZ)では、耐食性の低下がよく見られます。 これは、高温により鋼構造の粒界に存在するクロムが析出し、局所的なクロム含有量が減少するためです。 クロムは耐食性に優れているため、その組成を減らすと粒界腐食が発生する可能性があります。

母材の硬化または軟化HAZ。

親材料の熱影響部(HAZ)は、親材料よりも硬くなったり柔らかくなったりする可能性があります。 これは極端な温度にさらされるためであり、母材の特性に依存します。

母材の硬化と軟化の両方が望ましくありません。 これは、硬化した材料が弾力性を失い、もろくなる可能性があるためです。 また、柔らかい材料は延性破壊に遭遇する可能性があります。

EndNote

研削および溶接プロセスは、金属強化プロセスです。 研削は、研磨加工を利用して材料の一部を切断し、滑らかにするプロセスです。 一方、溶接は、溶融と溶融によって2つの材料を結合します。

研削および溶接プロセスは、厳しい温度にさらされるようなものです。 粉砕中の温度は最大1000℃に達する可能性があります。 溶接中は、最大10,000℃以上に達する可能性があります。

この温度上昇は、研削または溶接される材料の物理的特性に影響を与えます。 粉砕プロセスは、製品の磁性と表面の完全性に影響を与える可能性があります。 一方、溶接は接合部で相変態を引き起こし、構造の変化により機械的特性が変化します。

これらのプロセスは両方とも、プラスチック押し出し、プロトタイピング、ラピッドCNC機械加工、脱ろうプロセスです。