그라인딩 및 용접 공정 중 재료에 대한 열의 물리적 영향

2020-10-26연마 및 용접 공정과 재료의 물리적 특성에 미치는 영향.

The 그라인딩 및 용접 프로세스 일반적으로 재료 표면을 향상시키기 위해 수행되고 두 개의 재료에 합류된다. 금속은 일반적으로 갈기 및 용접 공정을받습니다. 그러나 다른 재료도 있습니다. 도자기 및 플라스틱과 같은.

Since metals are good conductors of heat, they sustain some physical effects due to these processes because of the high temperature involved. This high temperature not only acts as an additional load on the materials but also alters the mechanical properties of the workpiece.

Welding is a high-temperature process that joins similar metals by fusion. While a workpiece undergoes grinding to smoothen its surface. The heat source in a grinding process is friction. The prolonged contact between the grinding wheel and the surface gives rise to this friction.

Intro to Grind and Welding Process

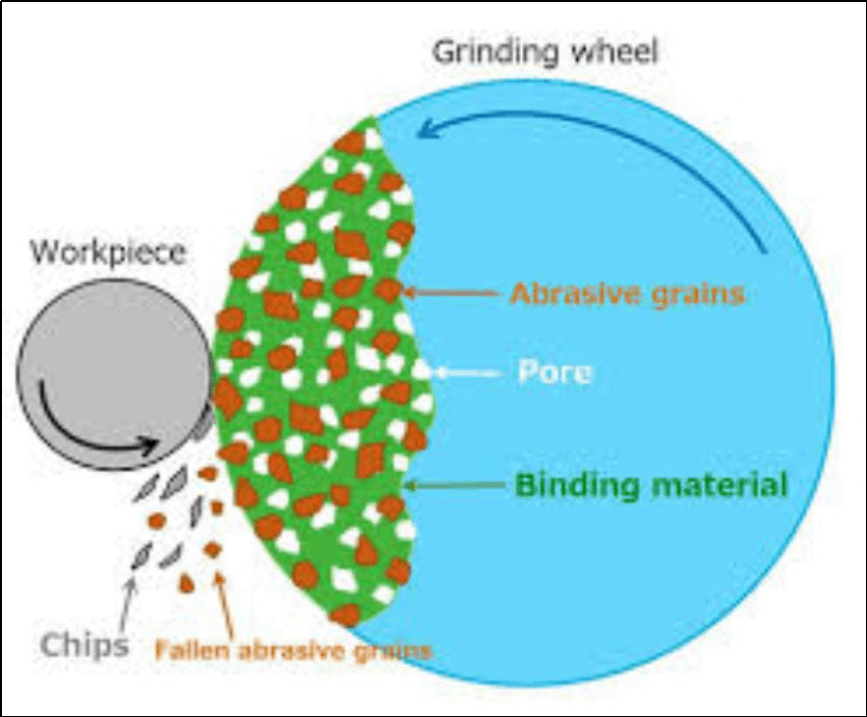

Grinding is classified as an abrasive machining process. A machining process is any process that removes a certain part of the raw material using cutting tools. Since small, abrasive particles perform cutting in this process. Therefore, it is called an abrasive machining process.

A workpiece requiring a smooth surface finish undergoes grinding. Usually, metals and ceramics go through this process.

In the case of grinding, the grinding wheel carries small abrasive particles. This grinding wheel rotates through an electrical motor. When the rotating grinding wheel comes in contact with the workpiece surface, it removes small parts of the surface and gives the workpiece a smoother finish.

The constant contact between the surface and grinding wheel gives rise to immense friction. This friction leads to the generation of heat which contributes to an increase in the temperature of both surfaces. This temperature rise often softens the workpiece and makes grinding easier.

The Welding Process:

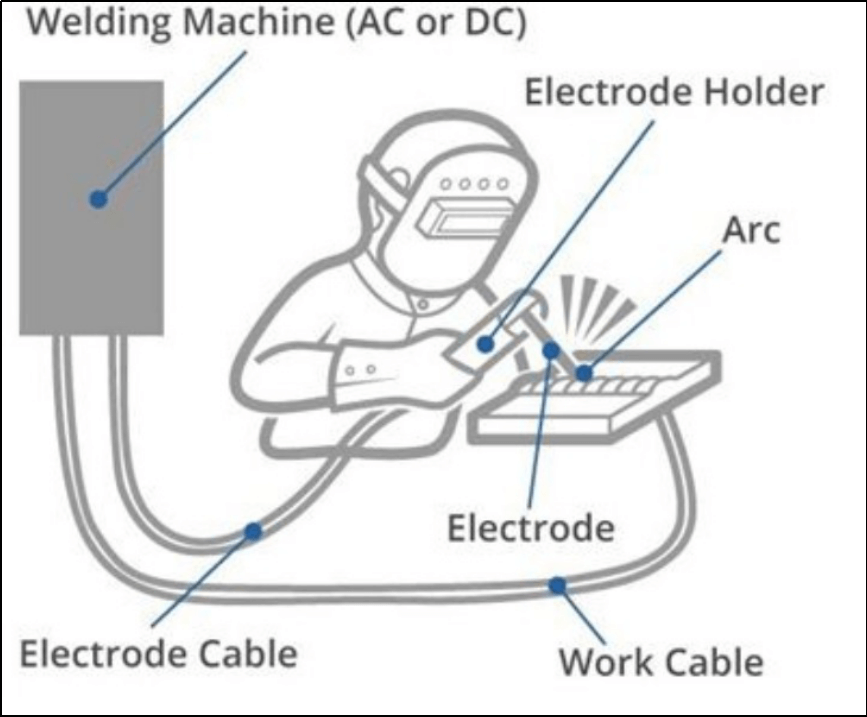

Welding is a process that joins two similar materials together by fusion. It is an extreme-temperature-process that melts the two parent materials from the junction point. This melted portion of the parent materials allows them to fuse. Cooling to ambient temperature forms a strong joint between the two parent materials. This joint is sometimes stronger than the parent materials.

The most common materials involved in the welding process are Iron and Steel. Though plastics can also be joined by welding. Acetylene reacts with oxygen and produces a welding flame. The temperature of this flame could be as high as 6000˚C-8000 ˚C and beyond.

Physical Effects of Grind and Welding Process

The grind and welding process is a high abrasion, high-temperature processes. Thus, they cause the material to sustain some physical effects.

Tensile Residual Stress

Residual stress is the stress that resides in the material after the stress source has been removed. The grind and welding process leave behind significant tensile residual stress. This tensile residual stress can be harmful because it can lead to fatigue and structural damage.

Physical Effects of Grinding process.

The grinding process generates high heat in the grinding zone because it is high friction. This heat causes the temperature to increase in the zone. This increase in temperature affects the physical properties of the materials.

The material, grinding depth, and speed of grinding determine the temperature the surface reaches during the process. Hence, the temperature of the workpiece may reach up to 900 ˚C-1000 ˚C during the process.

Formation of chips

The excess material removed during grinding could accumulate on the surface of the workpiece in the form of chips. This could affect the working efficiency of the grinder and undermine the results of the process. This is why grinding operation requires a lubricant. The main purpose of this is to capture the small particles that the grinding wheel removes from the surface. And to keep them from accumulating on the surface.

Damaged Surface Integrity

Surface integrity is the condition of the surface after it has undergone a mechanical process. Researches show that the grinding process leads to the formation of a layer of fragmented pieces on the workpiece which reduces the surface integrity of the piece.

Loss of Magnetism

Metals such as Iron are magnetic. Magnets tend to lose a percentage of their magnetism with every degree rise in temperature. This loss of magnetism may be reversible, irreversible, or permanent.

The temperature reached during the grinding process is very high in the grinding zone. If this process continues without a coolant, the magnetic material may end up losing its magnetism reversibly, irreversibly, or permanently depending upon the temperature.

Physical Effects of Welding Process

Welding being a high-temperature fusion process exposes the workpiece to extremely high temperatures. This heat is distributed in the vicinity of the welded joint.

극한 온도에 노출되면 용접 접합부 근처에 열 영향 영역 (HAZ)이 형성됩니다. 이 영역은 고온 용접 영역과의 근접성으로 인해 용융되지 않았지만 기계적 특성의 지속적인 변화를 겪지 않은 모재의 일부로 분류됩니다.

위상 변환

용접은 금속의 용융 및 냉각을 포함하기 때문에 금속은 처음에 고온에서 용융 된 다음 주위 온도로 냉각 된 후 구조적 변화를 겪습니다. 금속 구조의 이러한 변화를 위상 변환이라고합니다.

상 변형은 금속의 구조를 변화시킬뿐만 아니라 인장 강도, 경도 및 연성 등과 같은 기계적 특성도 변경합니다.

부식 저항 감소

부식 저항 감소는 강철의 열 영향 영역 (HAZ)에서 종종 발생합니다. 이는 고온으로 인해 강철 구조의 입계에 존재하는 크롬이 침전되어 국부 크롬 함량이 감소하기 때문입니다. 크롬은 내 부식성이 높기 때문에 구성이 감소하면 입계 부식이 발생할 수 있습니다.

모재의 경화 또는 연화 HAZ.

상위 재질의 HAZ (열 영향 영역)가 상위 재질보다 더 단단하거나 부드러워 질 수 있습니다. 이는 극한 온도에 노출되기 때문이며 모재의 특성에 따라 다릅니다.

모재의 경화와 연화는 모두 원하지 않습니다. 경화 된 재료는 탄성을 잃고 너무 부서지기 때문입니다. 그리고 부드러운 재료는 연성 파괴에 직면 할 수 있습니다.

EndNote

The Grind and welding processes are metal enhancement processes. Grinding is a process that utilizes abrasive machining to cut some part of the material to make it smoother. Welding, on the other hand, joins two materials by melting and fusion.

Grind and welding processes are such that they involve exposure to severe temperatures. The temperature can reach up to 1000 ˚C during grinding. While during welding, it can reach up to 10,000 ˚C and beyond.

This increase in temperature affects the physical properties of the materials that are ground or welded. The grinding process may affect the magnetism and surface integrity of the product. While welding causes phase transformation at the joint which leads to changes in mechanical properties owing to the change in structure.

Both these processes important to perform a number of 플라스틱 압출, Prototyping, Rapid CNC machining, Dewaxing Process and several other processes.