Физическое воздействие тепла на материалы в процессе шлифовки и сварки

2020-10-26Grind and Welding process and their effects on the physical properties of materials.

Процесс grind and welding process is usually performed to enhance the material surface and join two materials together. Metals usually receive a grind and welding process. But there are other materials too. Such as ceramics and plastics.

Поскольку металлы являются хорошими проводниками тепла, они испытывают некоторые физические эффекты из-за этих процессов из-за высокой температуры. Эта высокая температура не только действует как дополнительная нагрузка на материалы, но также изменяет механические свойства заготовки.

Сварка - это высокотемпературный процесс, при котором одинаковые металлы соединяются плавлением. При этом заготовка подвергается шлифовке для сглаживания ее поверхности. Источником тепла в процессе измельчения является трение. Продолжительный контакт между шлифовальным кругом и поверхностью вызывает это трение.

Введение в процесс шлифования и сварки

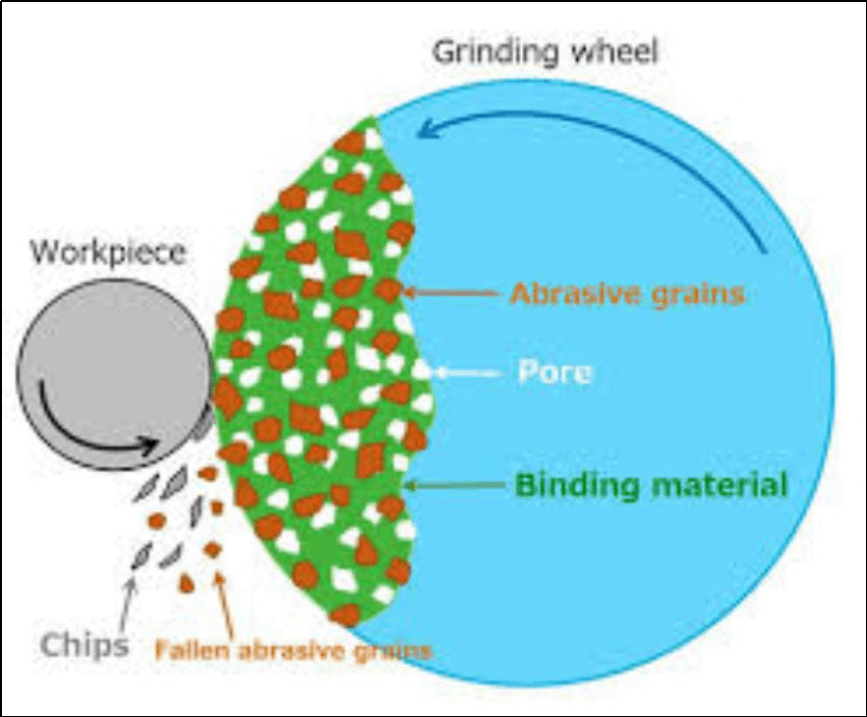

Grinding is classified as an abrasive machining process. A machining process is any process that removes a certain part of the raw material using cutting tools. Since small, abrasive particles perform cutting in this process. Therefore, it is called an abrasive machining process.

A workpiece requiring a smooth surface finish undergoes grinding. Usually, metals and ceramics go through this process.

In the case of grinding, the grinding wheel carries small abrasive particles. This grinding wheel rotates through an electrical motor. When the rotating grinding wheel comes in contact with the workpiece surface, it removes small parts of the surface and gives the workpiece a smoother finish.

The constant contact between the surface and grinding wheel gives rise to immense friction. This friction leads to the generation of heat which contributes to an increase in the temperature of both surfaces. This temperature rise often softens the workpiece and makes grinding easier.

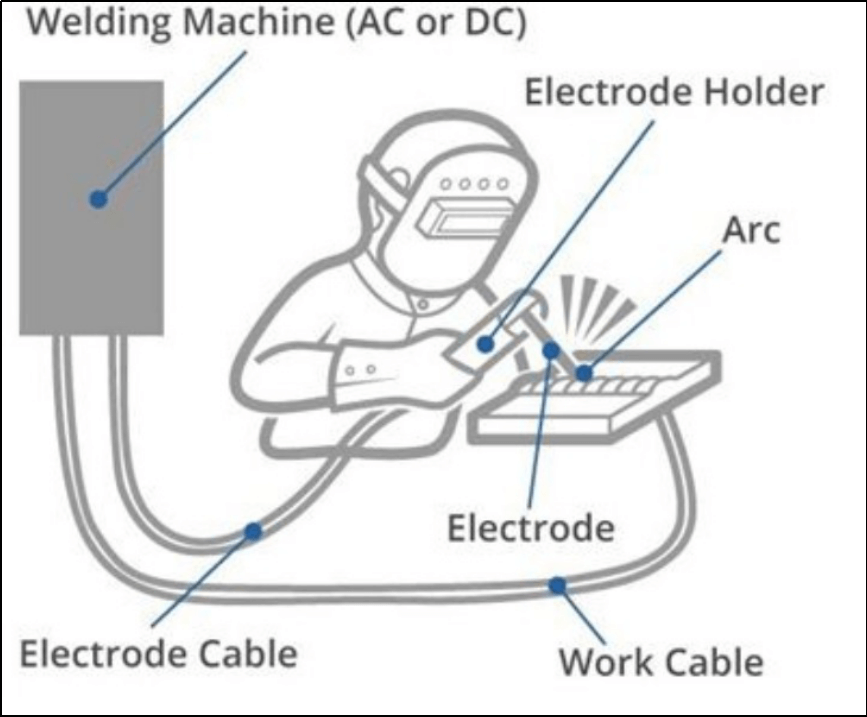

The Welding Process:

Welding is a process that joins two similar materials together by fusion. It is an extreme-temperature-process that melts the two parent materials from the junction point. This melted portion of the parent materials allows them to fuse. Cooling to ambient temperature forms a strong joint between the two parent materials. This joint is sometimes stronger than the parent materials.

The most common materials involved in the welding process are Iron and Steel. Though plastics can also be joined by welding. Acetylene reacts with oxygen and produces a welding flame. The temperature of this flame could be as high as 6000˚C-8000 ˚C and beyond.

Physical Effects of Grind and Welding Process

The grind and welding process is a high abrasion, high-temperature processes. Thus, they cause the material to sustain some physical effects.

Tensile Residual Stress

Residual stress is the stress that resides in the material after the stress source has been removed. The grind and welding process leave behind significant tensile residual stress. This tensile residual stress can be harmful because it can lead to fatigue and structural damage.

Physical Effects of Grinding process.

The grinding process generates high heat in the grinding zone because it is high friction. This heat causes the temperature to increase in the zone. This increase in temperature affects the physical properties of the materials.

The material, grinding depth, and speed of grinding determine the temperature the surface reaches during the process. Hence, the temperature of the workpiece may reach up to 900 ˚C-1000 ˚C during the process.

Formation of chips

The excess material removed during grinding could accumulate on the surface of the workpiece in the form of chips. This could affect the working efficiency of the grinder and undermine the results of the process. This is why grinding operation requires a lubricant. The main purpose of this is to capture the small particles that the grinding wheel removes from the surface. And to keep them from accumulating on the surface.

Damaged Surface Integrity

Surface integrity is the condition of the surface after it has undergone a mechanical process. Researches show that the grinding process leads to the formation of a layer of fragmented pieces on the workpiece which reduces the surface integrity of the piece.

Loss of Magnetism

Metals such as Iron are magnetic. Magnets tend to lose a percentage of their magnetism with every degree rise in temperature. This loss of magnetism may be reversible, irreversible, or permanent.

The temperature reached during the grinding process is very high in the grinding zone. If this process continues without a coolant, the magnetic material may end up losing its magnetism reversibly, irreversibly, or permanently depending upon the temperature.

Physical Effects of Welding Process

Welding being a high-temperature fusion process exposes the workpiece to extremely high temperatures. This heat is distributed in the vicinity of the welded joint.

Exposure to extreme temperature cause Heat-Affected-Zones (HAZs) to form near the welded joints. These zones are classified as part of the parent material that did not undergo melting yet sustained changes in their mechanical properties due to their proximity to the high-temperature welding zone.

Phase Transformation

Since welding involves melting and then cooling of the metal, the metal undergoes a structural change after first melting at high temperature and then cooling down to the ambient temperature. This change in the structure of the metal is called phase transformation.

Phase transformation not only changes the structure of metal but also alters its mechanical properties such as tensile strength, hardness, and ductility, etc.

Reduced Corrosion Resistance

Пониженная коррозионная стойкость часто встречается в зонах теплового воздействия (ЗТВ) стали. Это связано с тем, что высокая температура вызывает выделение хрома, присутствующего на границах зерен в структуре стали, что приводит к снижению локализованного содержания хрома. Поскольку хром очень устойчив к коррозии, уменьшение его состава может привести к межкристаллитной коррозии.

Затвердевшая или размягченная ЗТВ в основном материале.

Зона теплового воздействия (HAZ) в основном материале может стать тверже или мягче, чем в исходном материале. Это связано с воздействием экстремальных температур и зависит от свойств основного материала.

Как затвердевание, так и размягчение основного материала нежелательны. Это связано с тем, что затвердевший материал может потерять эластичность и стать слишком хрупким. Мягкий материал может подвергнуться пластическому разрушению.

EndNote

The Grind and welding processes are metal enhancement processes. Grinding is a process that utilizes abrasive machining to cut some part of the material to make it smoother. Welding, on the other hand, joins two materials by melting and fusion.

Grind and welding processes are such that they involve exposure to severe temperatures. The temperature can reach up to 1000 ˚C during grinding. While during welding, it can reach up to 10,000 ˚C and beyond.

This increase in temperature affects the physical properties of the materials that are ground or welded. The grinding process may affect the magnetism and surface integrity of the product. While welding causes phase transformation at the joint which leads to changes in mechanical properties owing to the change in structure.

Оба эти процесса важны для выполнения ряда процессов Пластиковая экструзия , прототипирования , быстрой обработки с ЧПУ , процесса депарафинизации и ряда других процессов.