Apa faedah yang disediakan oleh pemesinan cnc berketepatan tinggi?

2020-09-29Proses pemesinan cnc berketepatan tinggi (Panduan Terkini 2020)

pemesinan cnc berketepatan tinggi hampir seperti komputer. Ia berfungsi mengikut program yang diberikan. Dalam bentuk rantai nombor tertentu, urutan pergerakan "badan" mesin dalam proses memproses bahan tertentu direkodkan - itu saja. Anda hanya perlu memahami dan menggunakan.

The processing process takes place as follows:

- peranti input "membaca" program

- menukarnya menjadi isyarat

- memori perantaraan "mengingati" semua ini

- dan menyimpannya untuk beberapa lama.

The active control unit compares those specified by the program using a feedback system displacement. And the actuator implements the received signals. The mechanism is up and running.

The machine performs basic and additional functions. The basis of work is the control of feed drives, and changing the speed or type of tool is an additional step.

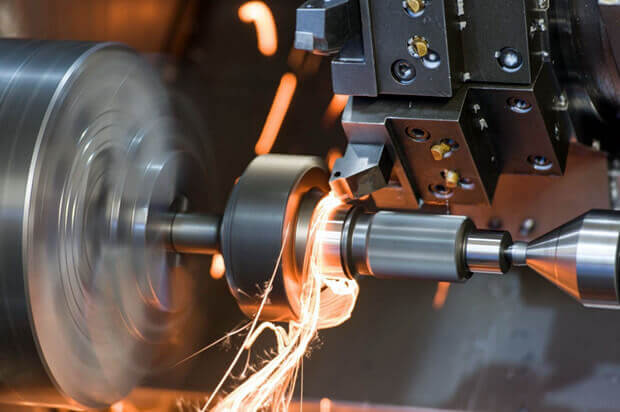

high precision cnc machining process

In pemesinan cnc berketepatan tinggi, there is a very convenient changeover system. Nothing needs to be unscrewed, unscrewed and screwed in again. It is enough only to replace the entered information. And the machine-worker will immediately perceive it.

And start a new business, honing the part ordered by the new program. It is this very moment that justifies the convenience of using CNC machines - a very quick reorientation.

CNC metal processing

What is the difference between metal processing and pemesinan cnc berketepatan tinggi? Here you don't need to think for a long time. In the first case, the whole process is intended for the worker who serves the machine. In the second, a programmer is involved. His task includes a very thorough study of the technical process. It comes with the smallest details.

How we classify cnc machines?

By the degree of versatility, CNC machines are distinguished as:

- universal

- designed for various operations

- a wide range in small-scale production

- for processing the same type of workpieces of different sizes

- and special for processing workpieces of the same name and one size in bulk production.

Any of these classified machines performs their work accurately, quickly and practically without interruption.

In addition, automatic pemesinan cnc berketepatan tinggi ensures:

- consistent quality

- the required roughness

- dimensional accuracy and shape

It ensures the identity of all parts of the same batch. And one more nuance: an automaton is not a person with fatigue or a bad mood characteristic of all living things - it will not fall asleep, it will not fail, it will not make a mistake.

Automation of the machine cycle allows you to turn any universal machine into a semi-automatic or automatic. It provides the possibility of multi-station service. Moreover, it has a very positive effect on labor productivity.

CNC turning: high precision cnc machining

CNC lathes, as a rule, are used when processing complex workpieces. It comes with multi-stage or with a curved surface. CNC turning is made easier by the fact that the automatic cycle provides multi-station service.

It means that the quantity is not created at the expense of quality. The tapping system is perfect for machining complex workpieces at high speeds.

With modern technology, pemesinan cnc berketepatan tinggi becomes less time consuming and tedious process. You might even say not tiresome at all. After all, the main work in this case is to create a program. And a modern CNC will ensure its execution according to a standard cycle.

What benefits high precision cnc machining provide?

The state-of-the-art pemesinan cnc berketepatan tinggi now gives the go-ahead for the implementation of the so-called end-to-end process. When all stages of creating a product, from development to the output of the finished product, are computerized and automated.

CNC lathes make up the lion's share. The main number of similar technological machines in the park. Carrying out their traditional technological operations, such as:

- boring and turning surfaces

- tapping

- drilling,

Smart machines approach the process so precisely and meticulously that the processing of parts becomes something akin to cloning.

CNC metal milling

When milling, we are usually interested in the following nuance: how to achieve high quality at low cost. And here, too, CNC machining will play a positive role.

Rough or finish milling is carried out, without a difference. In either case, the details in programming cannot be ignored. Milling CNC metal - is a tricky business. Though it is not associated with noble metals.

Therefore, in factories where new equipment appears. No matter who does not work. Specialists undergo training, some even abroad.

So, by means of pemesinan cnc berketepatan tinggi, as the most common of machining, three types of processing of simple surfaces are carried out. And the technological capabilities of CNC machines of the milling group are determined by their:

- design

- technical characteristics

- layout and accuracy class

high precision cnc machining comes with high production ability

One way or another, milling on CNC machines is characterized by high productivity. And it allows you to get parts with a geometrically perfect surface. By the way, milling can easily replace grinding by using cutters equipped with modern cutting materials.

pemesinan cnc berketepatan tinggi is used in many areas of life. Such services are becoming a necessity in:

- the advertising business

- in the woodworking and

- native metalworking spheres

CNC milling is designed to create a perfect part, even with a complex and hard-to-reach surface. The complexity of the form is not a hindrance if the machine has high precision and cleanliness of processing.

Large, small batches - it makes no difference for a CNC machine. Working according to a given program, the machine easily copes with milling any volume of products.

Mengapa anda harus memilih pemesinan cnc berketepatan tinggi?

Dengan mengurangkan kadar sekerap dan meningkatkan produktiviti, mesin ini siap berfungsi untuk orang-orang siang dan malam. Pada masa lalu, mereka pasti akan dianugerahkan gelaran pahlawan buruh sosialis.

Mematuhi program, pemesinan cnc berketepatan tinggi dapat memproses apa sahaja. Dan bagaimana yang kita mahukan, membolehkan seseorang bertanggungjawab dalam semua proses. Peranan pekerja dikurangkan hanya untuk memantau operasi mesin.