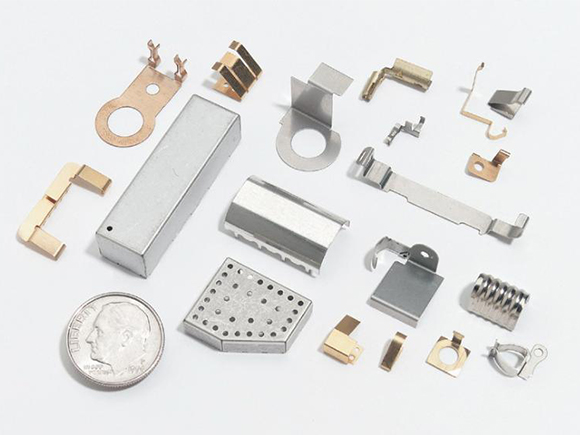

Pembuatan Logam Lembaran

Kaedah pemprosesan asas bahagian logam lembaran adalah seperti berikut: mengosongkan, membongkok, meregangkan, membentuk, dan mengimpal. Spesifikasi ini menerangkan keperluan proses yang perlu diberi perhatian untuk setiap kaedah pemprosesan.

(Logam lembaran, pengosongan, lenturan, peregangan, pembentukan, susun atur, jejari lenturan minimum, burr, springback, dead edge, welding)

According to the different processing methods, the blanking can be divided into ordinary punching, several punching, shearing, blanking, laser cutting, and wind cutting. Due to different processing methods, the processing technology of blanking is also different. Sheet metal cutting methods are mainly digital punching and laser cutting. Digital punching is processed by CNC punching. The thickness of the sheet is processed by cold rolled sheet and hot rolled sheet less than or equal to 3.0mm, aluminum sheet less than or equal to 4.0mm, and stainless steel less than or equal to 2.0 mm