What are the benefits of CNC machining for Precision machining part industry?

2020-07-06The advantages of high precession machining

What is Precision machining part?

Precision machining part is basically a procedure. In which raw material has to remove from a component in order to fabricate a final product.In precision machining, engineers do this process with the product when it is very close to the final preparation.

This process requires following procedures. Such as:

- Cutting

- Milling

- Turning

- Electrical discharge machining.

Furthermore, to perform this process, manufacturers need the equipment. And they basically use CNC based equipment. It is actually a kind of technical manufacturing. And it is very important in order to create, fabricate and design the following:

- Designing machines

- Parts

- Tools

- And many other type of hardware which is very crucial in advanced manufacturing.

In this process, Precision machining part shapes the large piece of unshaped material into final design. And hence they will be able to perform their specific functions.

What is CNC machining that engineers need for Precision machining part?

It is generally known as CNC machining. It is basically a format of subtractive manufacturing. And manufacturers use it to create various components with some materials.

Furthermore, types of these materials are:

- Engineering plastics

For the purpose of manufacturing components manufacturers use this process. And CNC machining generally use prescheduled software of computers. As a result, this software actually instructs the machines how to draw out the exact material from a raw one.

In order to complete these functions, CNC machines will carry numerous steps for generating the required profile. The procedure of extracting has managed with the help of motorized cutting tools.

How many types of CNC machining are there which engineers need for Precision machining part?

There are basically two types of CNC machines which engineers use for Precision machining part.

And these are:

- Lathes

- Mills

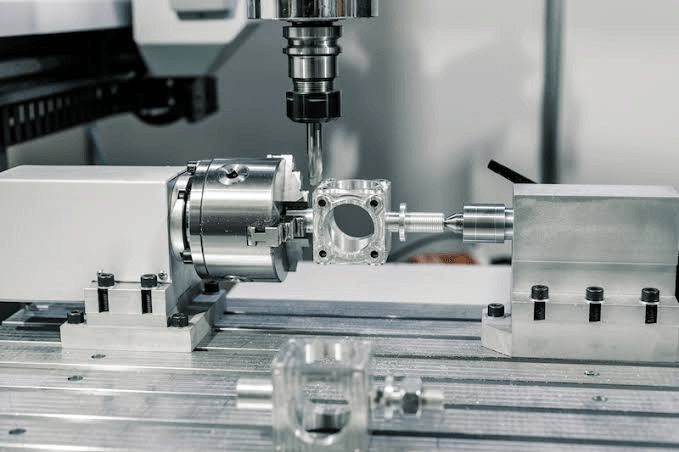

Perfect CNC machine which mills perfectly always makes use of cylindrical cutting instruments. Because these instruments have the ability to rotate in several routes and directions. So that they can extract the raw material from the object and can convert it in a desired shape.

This milling cutter actually has the capability to rotate in various axes. Hence it can easily produce the final design. CNC mill actually consists of 3 and 5 axes.

What are the benefits of CNC machining for Precision machining part?

There are several benefits of CNC machining. And they are also extremely beneficial for Precision machining part. Some of these are:

- Efficient

- Cost effective

- High accuracy

- Superior quality

Here are details of these advantages.

Efficient

CNC machining is highly speedy and quite sensible in order to turn around times. The time set-up of CNC machines is relatively less in comparison to other methods of manufacturing. It saves the time as the engineers know that time is money.

It also has the ability to easily repeat the given task again and again. Once the engineers create the design, they give instructions to CNC machines for Precision machining part. These CNC machines have the ability to repeat it again and again with perfect accuracy.

Cost effective

CNC machining is infact a cost effective procedure of various components and it is also applicable for manufacturing prototypes. It is also cost effective for:

- Small batch

- Medium batch

- Larger batch.

High accuracy

In CNC machining engineers use CAD process. And to make use of CAD is a perfect choice. Because it provides high rate of accuracy ofmachine tolerance of +/-0.1mm.

Superior quality

The CNC machines are connected with greatly efficient parts. These parts have perfect and brilliant physical features. CNC machining has the ability to perform high power task.

So, when it comes to evaluate high performances task, CNC machining will be a perfect choice of engineers.

What does a Precision machining part require for processing?

In order to achieve high quality performance, precision machining needs the extreme quality of blueprints. And for this purpose engineers prefer to use blueprints of high quality and better durability. These blueprints generally belong to the following CAM and CAD programs. Such as:

- TurboCAD

- AutoCAD

When engineers want to manufacture a Precision machining part, they prefer to use this software. As these software may assist to fabricate more complicated 3D outlines or diagrams. Furthermore, these blueprints have the power to make sure that the final product will be the best in all phases.

It is true that most of precision machine partcompanies like to work with the programs of CAM/CAD. But it is also a real fact they often like to work with the help of hand-drawn sketches.

Because these sketches may be quite helpful in the introductory phases of final design. But these need high quality of time. Hence CNC machining is best in order to meet all the conditions.

For how many materials Precision machining part is used?

Nowadays precision machining has used on number of different materials to shape them perfectly.

Such as:

- Steel

- Bronze

- Graphite glass

- Few kinds of plastics.

It totally depends on the size of the targeted project. And it also depends on the material for which precision machining is using. For different purposes manufacturers use different types of precision machining.

How many kinds of tools are there which engineers use in precision machining part?

There are various precision machining tools which engineers will use to meet different purposes. And it also depends on the kind of projects of Precision machining part.

These are:

- Lathes

- Milling machines

- Drill presses

- Saws and grinders

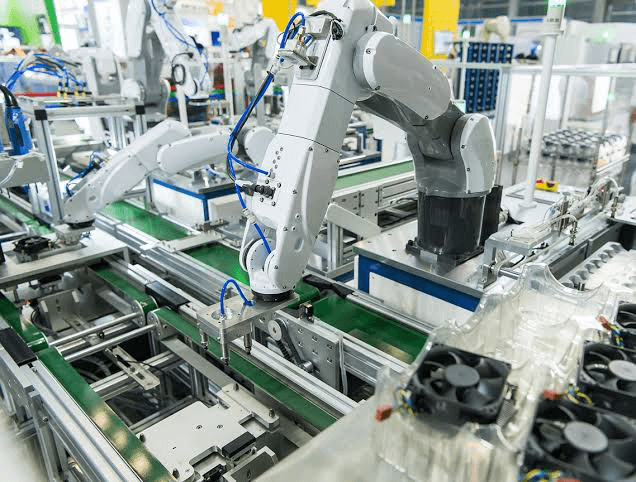

- And even high-speed robotics can also be used.

Which kinds of industry use precision machining part?

There are numerous kinds of industries which use different kinds of precision machining parts.

And these are:

- The industry of aerospace will use high-velocity machining.

- The industry of woodwork tool-making may use different machining parts.

These several kinds of precision machining parts are:

- Photo-chemical etching

- Milling processes.

These machines are actually enabled for some special needs. Engineers can use this Precision machining part for several purposes. For example, these task purposes can be small or large quantities. They may be thousands or less then it. But sometimes they can grow higher.

Furthermore, precision machines usually need a supervision of computer numerically controlled. And these CNC instruments or tools permit the exact and targeted task to be done.

Precision machining part Material Conversion

As we have already explained that precision machining convert the different kinds of metal components into the final shape or design. In this procedure machines have the ability to remove raw or rough from a material in order to shape it perfectly.

SO, In other words, in the process of Precision machining part, engineers reshape the large block of a specific material into a perfect form or shape.

Actually it is a basic manufacturing procedure in which engineers customize the product to its fullest and final shape. It has become critical and essential in many industries. It is a real fact that almost every kind of industry needs this technology.

And without precision machining part, it is not possible to convert raw material into extra applicable need. Moreover, these industries are:

- Aeronautical

- Biomedical

- Nano-technological

How many advantages of Precision machining part provide?

It is necessary to understand consistent operations of precision machining. So that manufacturers can attain the desired result. For this purpose engineers must have the deep and intense mechanism about precision machining process.

Because it has become an essential and necessary process in modern day technology. And precision machining has several benefits. Some of its advantages are:

- Improved speed

- Operational efficiency

- Low production cost

- Reduced risk factors

- Fast production.

Improved speed:

These precision machines have designed to understand and interpret blueprints. And have designed to perform according the instructions given by CNC machines. The great benefit of Precision machine part is that, they have no need to rest or sleep.

Hence they can perform at best level and need no time for rest. They can execute for a long time period with perfect and consistent quality.

Operational efficiency:

These machines have designed with CNC machines. And they can easily perform automatically with great speed. Moreover, they do not need any type of human interactions. But it is necessary to hire a fully skilled labor to handle this more advanced system.

Precision machining part Low production cost:

In order to manufacture precision parts and components engineers use CNC machines. Because Precision machine part execute perfectly by following ways:

- Less labor

- Reduced waste material

- Minimal possibility of error.

And it has low cost of production for large budget tasks. Hence precision machining part is low budget process even for extra-large budget program.

Reduced risk factors:

It is a real fact that errors can occur from both mechanical and human procedures. And hence they can increase the cost of production. But when engineers use computerized machines like precision machines.

Then they have less chance to create errors. So, Precision machine part is best way to reduce the risk factors.

Fast production

As engineers know this fact that automatic manufacturing system can execute hard and big tasks with perfect accuracy. Human beings can never beat these machines because of their accuracy and speed. They have the abilities to do the fast production in no time with great exactness.

Conclusion:

Precision machines are best ways to execute small and large components which we use in our daily life. You have to believe that even a little piece of your daily use has fabricated with the help of precision machine.

Precision machines are necessary for following industries like:

- Automobiles

- Surgical devices

- Aircraft parts.

Hence, Precision machining part is a best way to solve and execute the difficult and tough projects. It has essential for our daily life as well as helpful for industrial usage.