How to choose professional custom fabrication services?

2020-07-035 tips for beginners to learn basics of customize fabrication

An Introduction to custom fabrication services

Sooner or later, every aspiring handyman deals with the custom fabrication services. Metal profiles made of aluminum, steel or stainless steel. However, are not as easy to process as wood due to their high-strength properties.

But it's not as complicated as you think. We have collected 5 tips to keep in mind when dealing with metal profiles.

The classification of metal custom fabrication

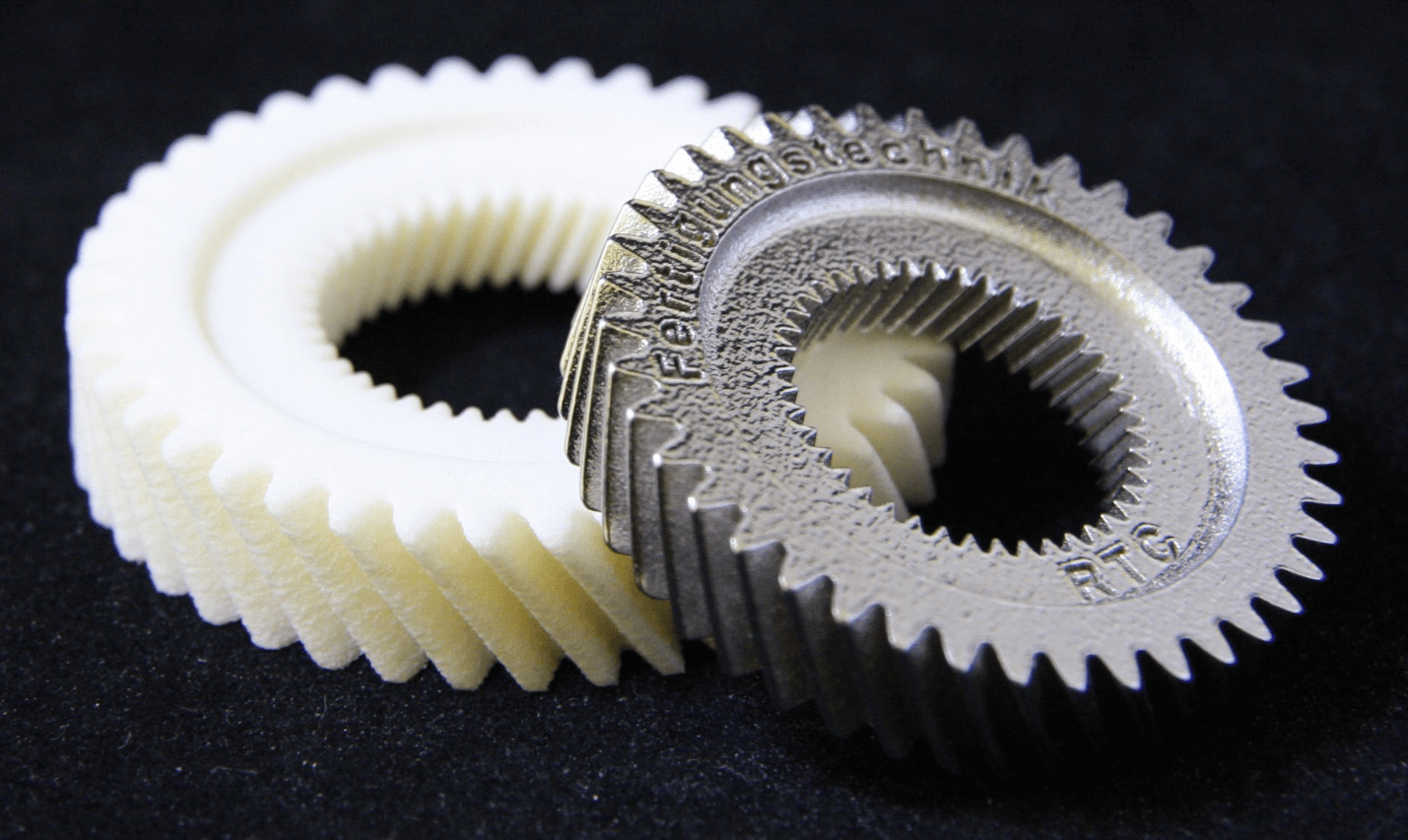

Before we look at a process, we first get an overview of custom fabrication services. It is divided into six large groups. The original form produces a solid body from an informal raw material. The plastic change of the shape of a solid body is described as forming.

The third group, separation, is defined by changing the shape of a solid body by locally breaking the cohesion. When work pieces are brought together, one speaks of joining.

The fifth group is coating. A material is influenced by a chemical reaction. For example, this step is classified in the "Change material properties" group.

How to start professional custom fabrication?

The first step is to heat the model of our component. The molding material, a resin-coated sand. It is then placed on the model. The heat causes the resin to liquefy and the grains of sand form a solid mass that then hardens. You can get this process from leading custom fabrication services companies.

Excess sand can be dumped and reused directly. Now we can already speak of the shape mask. The sand mass is further hardened under the influence of heat until it can finally be detached from the model.

Custom fabrication services carry these steps for both mold halves that are glued together. In the last step, the liquid metal or alloy is poured into the cavity between the bonded mold mask halves.

What are safety measures for metal custom fabrication services?

- Safety comes first: protective clothing for metal processing.

Protective clothing is also mandatory for metal processing. The type of injury can be much higher for metal. Where you fight a splinter on wood, pieces of metal can produce major injuries.

Safety glasses, protective gloves and, for heavy profiles, safety shoes are also mandatory. With gloves you should make sure that they are not plastic gloves. Professional custom fabrication services also follow the same pattern.

Depending on the job, high temperatures can arise during metal processing. From which plastic gloves offer no protection. Turning is an exception to the compulsory use of gloves. The glove can get caught on a spindle and therefore even increase the risk of injury.

Custom fabrication services should always clamp Work pieces firmly. If the profile jams when drilling or cutting, the material can injure the craftsman.

2. Which metal for which purpose- custom fabrication services?

As a beginner, you may be wondering which material is suitable for which purpose. Here is a small overview for a rough classification.

Steel is the all-rounder of metals. Steel profiles are very cheap and can be processed relatively easily. That is why steel is suitable for most projects. The disadvantage is the high weight and the susceptibility to rust.

Corrosion protection with varnish is therefore practically mandatory and use outdoors is therefore only conditionally recommended.

Aluminum is the lightweight among metals. The “soft” material is easy to work with common hand tools and is magnetically neutral. The self-generating oxide layer makes the aluminum particularly corrosion-resistant. It is therefore also well suited for custom fabrication services.

Unfortunately, the protective layer becomes a little milky after a while. which is only an optical flaw. It should also be mentioned that the material is unfortunately only moderately bendable.

Stainless steel lives up to its name. If weight is not a factor, it is the king of materials. It is high-strength, corrosion-resistant. It offers a classy look that can be maintained with a little care. The hard material can unfortunately only be processed with the tools provided and is the most expensive of the three materials due to the special alloy.

3. Custom fabrication services correctly process metal

Since metals are hard, tools must be used that are just as tough and have the necessary degree of hardness. The harder the workpiece, the harder the tool must be. Here you should pay attention to the labels when shopping. If you feel any difficulty, you contact nearest custom fabrication Services Company.

Rusting steel can contaminate stainless steel. In extreme cases, the stainless steel can even corrode. Therefore, tools with which steel has been processed should not be used for stainless steel work. You can find out more about this topic by contacting best custom fabrication services.

Drilling - which drill for which metal

So that drilling is not a stress test for metal, tools and nerves, there are a few points that should be considered:

It is best to use a drill with adjustable speed for metal processing. The ideal drilling speed depends on the diameter of the drill and the cutting speed specification for the material.

The correct drilling speed can then be calculated using the formula: cutting speed / pi * drill diameter. The speed should be further reduced for hardened metal.

Since metals have hard and smooth surfaces, these should be prepared before drilling. The drilling point is marked with a scribing needle. If necessary, pre-drilling can also take place. These are the most common method custom fabrication services provide.

How do custom fabrication services maintain correct feed?

The correct feed should be ensured when drilling. If this is too high, the wear on the tool increases and in the worst case it can break. Depending on the material, cooling is necessary. Special drilling oils can be used for this.

The choice of drill is based on the metal profile to be machined. In general, HSS drills are suitable for metal work. If you are unsure, ask the custom fabrication services on site.

Custom fabrication services Saw metal

Everyone knows the commercially available hand hacksaw. Compared to the saw blades of wood saws, metal saws have more teeth per centimeter. These are necessary to separate the hard and tough material. The fuller the material, the coarser the number of teeth.

Sawing metal with a hand saw puts a lot of strain on the muscles. But it requires less effort. However, the electric saw requires some preparation. With both methods you should of course clamp the workpiece firmly.

In addition, one should pay attention to the cutting speed of the metal with electric sawing.

4. Connect metals

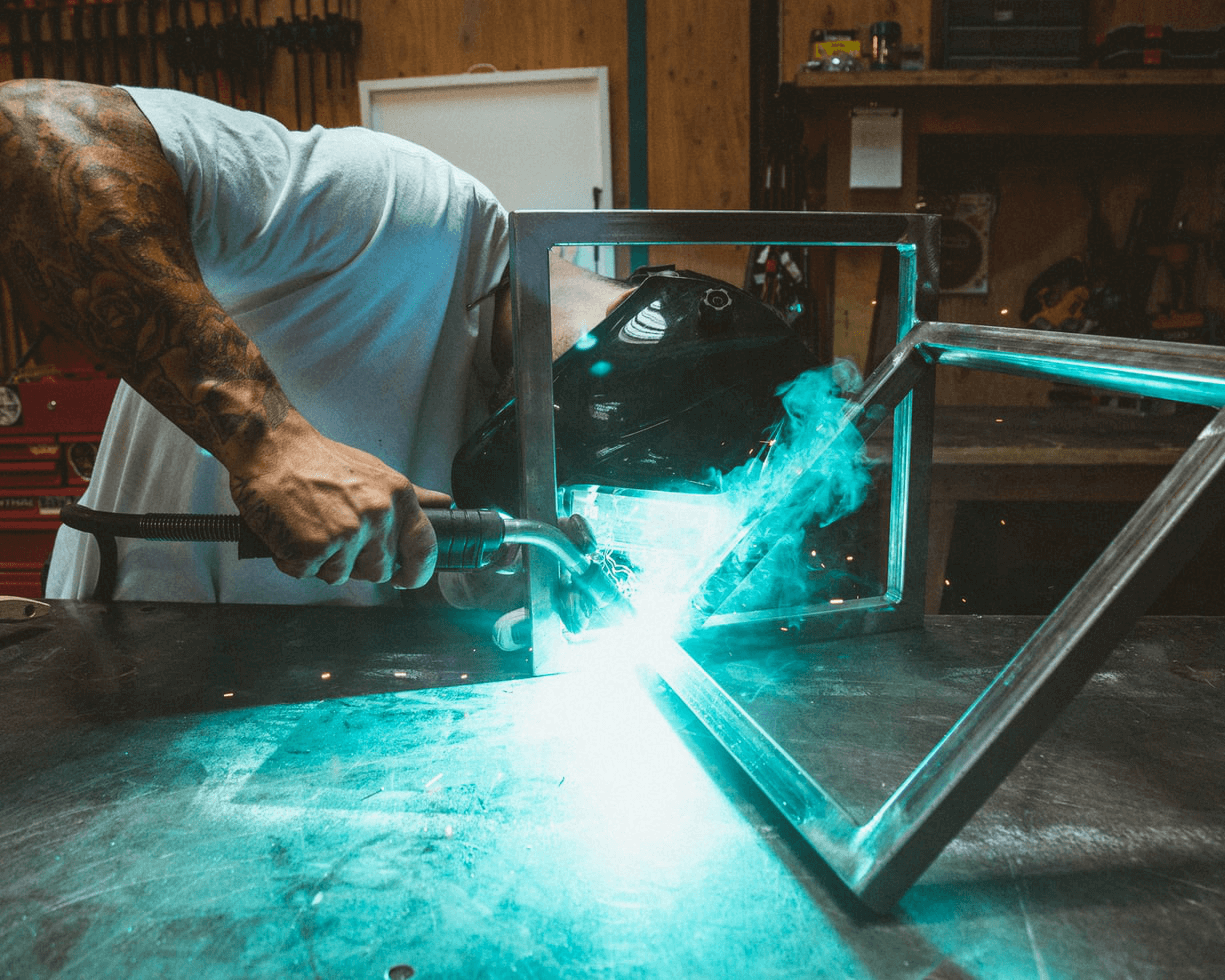

It doesn't always have to be welding to connect metals together.

Gluing metals

When it comes to metal, you don't immediately think about gluing. Custom fabrication services adhesive technology is a very simple joining process. It can be easily implemented by a layperson. Large-area materials such as sheet metal or angle profiles can be glued wonderfully.

There is a special adhesive for metal, which preferably consists of two components. It is advisable to carry out a few tests in advance. Professional custom fabrication services can also glue metals to other materials. Such as:

- Glass

- plastic

- wood

Custom fabrication services Screwing of metals

Alongside welding, screwing is one of the most common joining techniques. This technique is particularly useful if you do not want to make permanent connections.

The implementation of screw connections basically only requires boreholes. A screw connection with a nut can then be used as required. Alternatively, depending on the material, a thread can be cut directly into the metal using a tap.

Here, too, it is possible to screw metals to other materials. It is a great advantage over welding. If you are not sure about it, you can contact custom fabrication services.

- Deburring - the most important thing at the end

Follow-up is mandatory. In order to avoid injuries at work and after completion, the workpiece should be free of:

- chips

- burrs

- Fraying

- Splinters and sharp edges.

For this purpose, a file or a flex should be used. This is a complicated task. I would suggest hiring expert custom fabrication services for this. The workplace should also be cleaned thoroughly in between with a broom to avoid later injuries.