Dicas eficazes para processos de retificação e soldagem

2020-08-25Como tornar o processo de retificação e soldagem eficaz e eficiente?

Apesar de todo o avanço tecnológico e automação, o processo de retificação e soldagem é e provavelmente continuará sendo uma operação intensamente manual. Quando a borracha entra em contato com a estrada, o conceito é difícil. Ou, para ser mais preciso, é quando o grão entra em contato com o metal.

Grinding can seem to be a simple process, however, for effective results, it is imperative to pay attention to details. The process demands applying the right amount of pressure on the correct angels. Doing so will ensure the removal of most metal in a short time.

There are several variables that are effective for the smooth flow of the parts. No matter how fast and the upgraded upstream process you use, it would take a parts day if not months to get through the grinding department.

This topic is extremely extensive; however, we do present some of the most effective tips to ensure the success of your grinding operations. These factors would provide you some initial ideas.

How to Ensure the Success of Grind and Welding Process

Right Tool

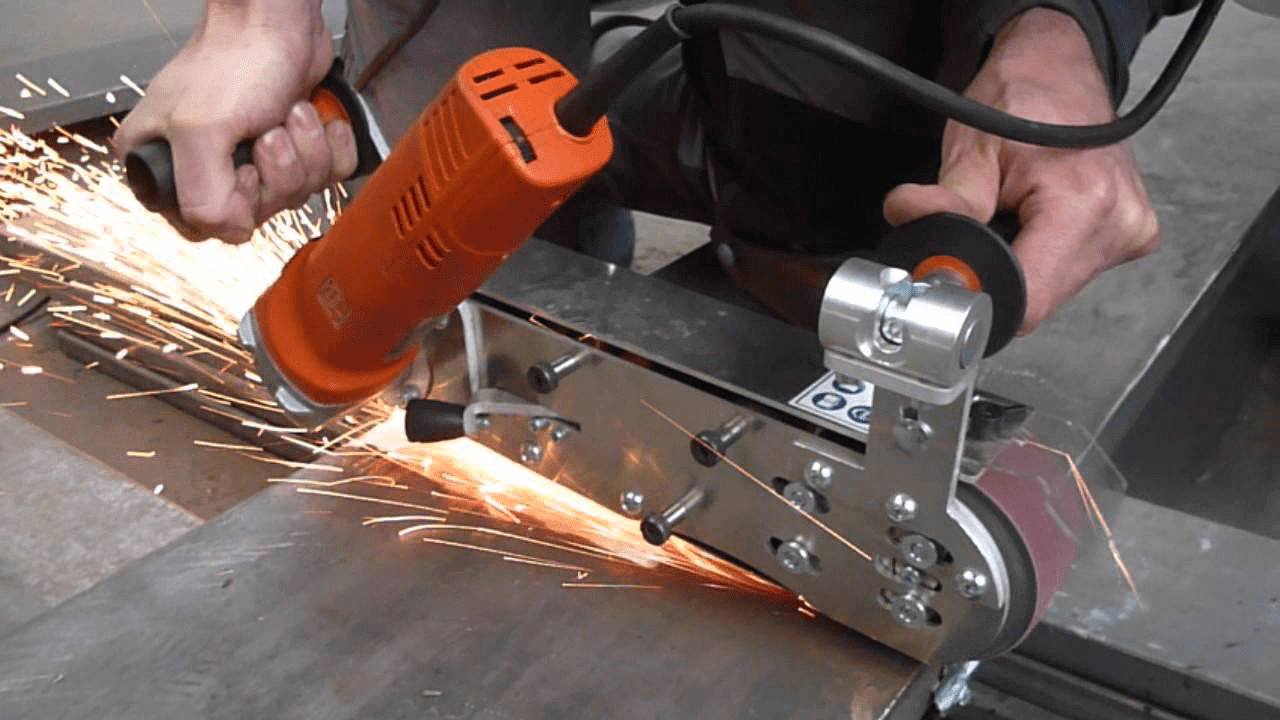

Certifique-se de que suas ferramentas elétricas não sejam consumíveis como os discos abrasivos. Portanto, você precisa ser seletivo quando se trata de moedores. Vá com qualquer um, na verdade, escolha aquele que pode lidar adequadamente com a amperagem do seu trabalho.

Por exemplo, se as aplicações requerem 8 a 10 amperes de pressão e você opta por 6 amperes, esmerilhadeira de ângulo reto. Podemos garantir que você está com problemas desde o início. À medida que o processo avançava, as coisas pioravam.

Como o moedor não é uma ferramenta que você jogaria fora, é altamente recomendável investir nele. Em vez de escolher qualquer triturador aleatório, opte por um triturador industrial de alta qualidade. Custaria quase o dobro, entretanto, você pode medir sua vida útil em anos, e não em semanas.

Tanto os discos flap quanto os discos de moagem são compatíveis com as rebarbadoras de ângulo reto. Combinando um moedor de baixa qualidade, discos de moagem de alta qualidade produziriam melhores resultados. No entanto, faltaria a suavidade dos esmeris e discos de esmeril de qualidade premium.

Segurança em primeiro lugar

Quando você usa a ferramenta certa para o trabalho, ela garante operações seguras automaticamente. Por exemplo, usar um moedor sem proteção abriria portas para muitos ferimentos em potencial. Além disso, se a OSHA calcular isso, a empresa teria que pagar uma multa pesada.

Sim, entendemos que o guarda pode ser problemático em algumas situações. No entanto, sem os guardas, as coisas podem ficar sérias. As coisas ficariam ainda piores se você estiver usando a ferramenta errada ou se tiver pouco poder.

So, if you are planning to grind in the tight areas, removing your guard and squeezing in the right-angle grinder is not the way to go about it. Use the file grinder. It would be the right tool to guarantee job efficiency and accuracy.

Before you change the abrasive media, it is important to unplug the tool. When changing the media, we recommend using the power tool’s head in order to lock the key button. Put the tool on your forearm, facing upwards. Now take your time and remove the abrasive.

Performing these steps would offer more control during abrasive changeout. In addition, it won’t allow the abrasive to drop. After all, dropped abrasive is among the commonly overlooked reason behind abrasive failure.

Also, the fall of the disc during a high-RPM right angle grinder can lead to some serious damage. You need to be extra careful as the smallest crack can make the discs lose during the operation. Too often the operators are putting back the disc after it drops out. Of course, they do inspect it first, but this is not a reliable and safe solution.

Spark Flow

Limited shops do have an ammeter at hand. It is a tool that you can use to keep a close check on the operator. It lets you determine whether the operator is pushing too hard or it is taking things lightly. It is possible to alter the change depending upon the grinding wheel and the tool.

Optimal pressure for the industrial grinding application ranges between eight to ten amps. In case, the ammeters show reading above this range, you need to slow down. However, if it shows below that range, you need to gear up.

Unfortunately, not all shops have ammeter at hand. Therefore, you need an alternative. The good news almost all applications produce sparks during the grind and welding process. Manufacturers use these sparks as an indication of the pressure. These sparks act as a visual ammeter.

Wondering how the sparks can help determine whether the process is working effectively or not? In most cases, the sparks would flow about three to four feet away from the work-place. If you find the sparks not following this particular pattern it means you are either overdoing it or underdoing it.

When you push too hard, it would overheat and overload the disc. This would result in the grains to glaze over. They would then become smooth. Since the grains are no longer cutting into the weld, therefore there would be spark reduction.

Likewise, when you are not pushing enough, you are not fully engaging in the workplace. Every disc rotation would not yield enough weld metal.

Pay heed to the Grinder Sound

The grinder’s sound is another effective way to figure out the problem. Applying the right pressure would produce a sound that has a contact pitch. In case, you are underdoing, the pitch volume would increase. In the case of overdosing, there would a drop in the volume.

The Right Working Angle of Grind and Welding Process

In general, you would have to use the grinding disc at angles that are five to ten degrees horizontal. Also, the pattern present on the disc face should be double its thickness. For example, if the pattern is 0.5” wide, the disc should be 0.25” thick.

If you have a disc thickness of 0.25”, but the wear pattern is let’s say 0.75” and your approach is flat. It means that you would the angle approach is not appropriate. It is too high, especially when several grinding disc’s grains will be engaging together.